Assembly instructions Contents

Linear motor axis LMSSA LMSSA-01-1-EN-2201-MA Seite 3von 44

Contents

1General information..................................................................................................................... 4

1.1 About this user manual ................................................................................................................................ 4

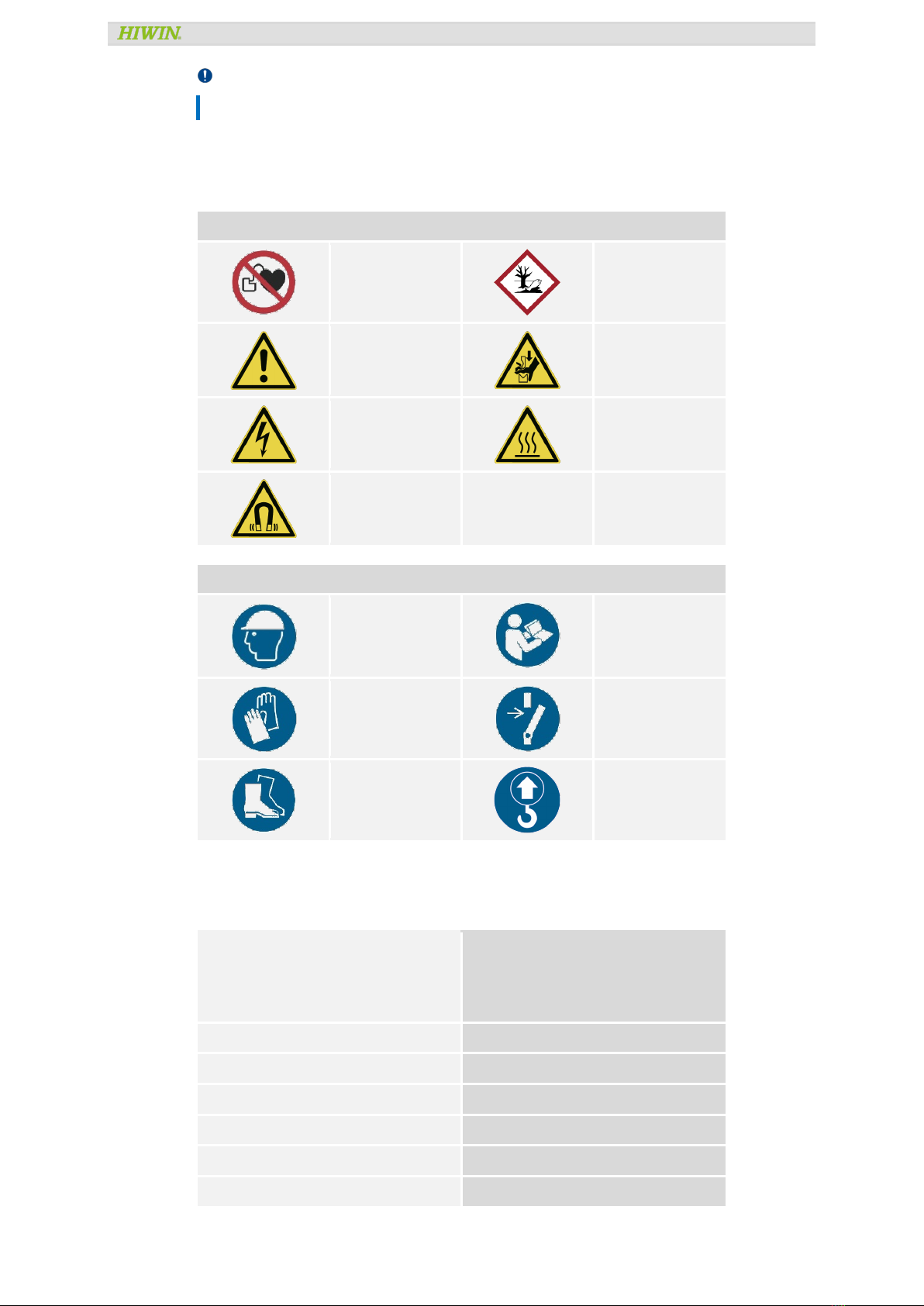

1.2 Depictions used in this user manual.............................................................................................................. 4

1.3 Manufacturer’s details ................................................................................................................................. 5

1.4 Product monitoring ...................................................................................................................................... 6

2Basic safety notices .................................................................................................................... 7

2.1 Intended use................................................................................................................................................ 7

2.2 Reasonably foreseeable misuse.................................................................................................................... 7

2.3 Conversions and modifications ..................................................................................................................... 7

2.4 Residual risks.............................................................................................................................................. 7

2.5 Personnel requirements ............................................................................................................................... 8

2.6 Protective equipment................................................................................................................................... 8

2.7 Labels on linear motor system...................................................................................................................... 9

3Description of the linear motor system..........................................................................................10

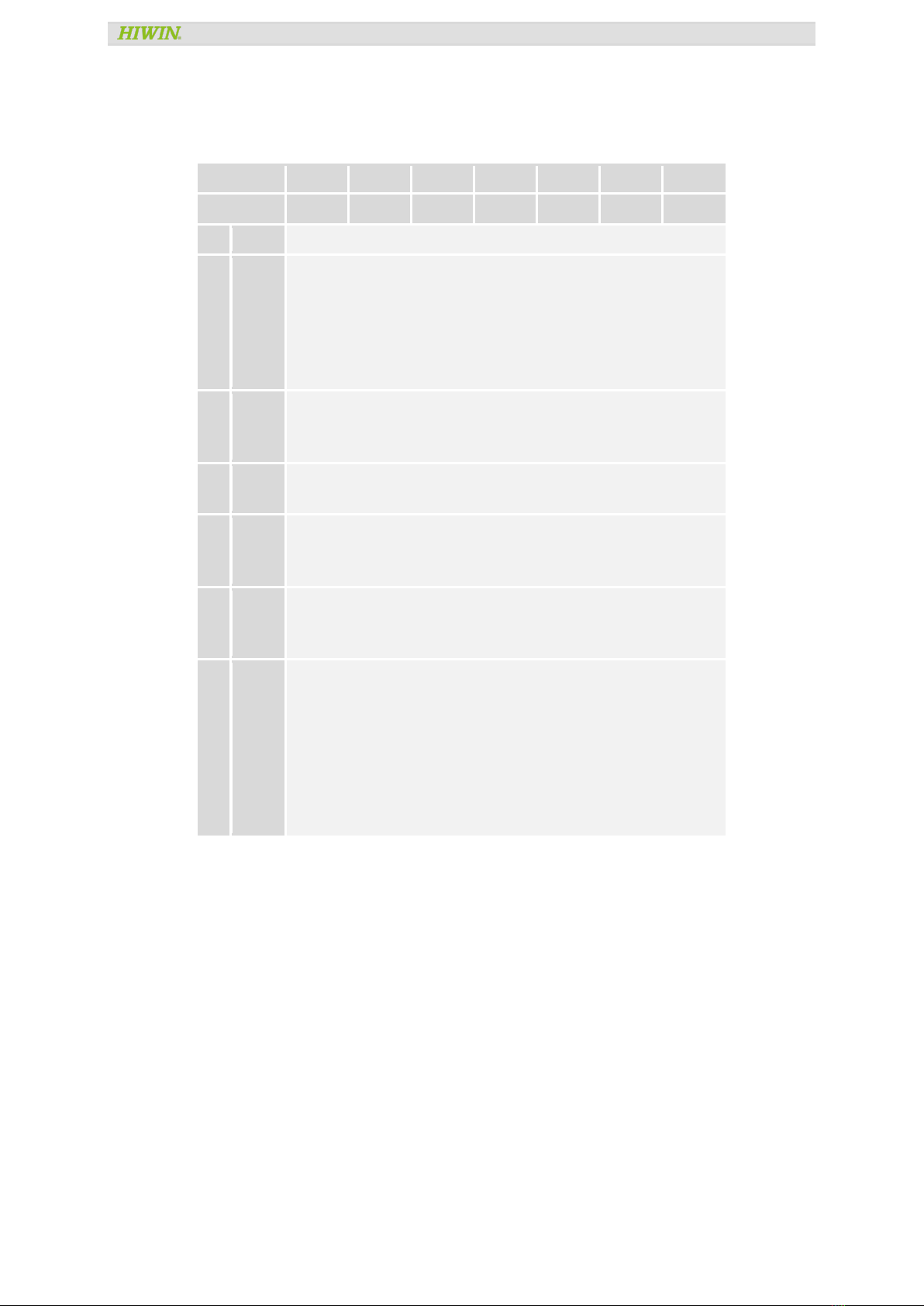

3.1 Order code..................................................................................................................................................10

3.2 Field of application .....................................................................................................................................11

3.3 Main components of the linear motor system ...............................................................................................12

3.4 Functional description.................................................................................................................................13

3.5 Linear motor-system...................................................................................................................................13

3.6 Linear motor ...............................................................................................................................................13

3.7 Positioning measurement system ................................................................................................................14

3.8 Limit switches (optional).............................................................................................................................15

3.9 Cable chain (optional) .................................................................................................................................15

4Transport and Installation ...........................................................................................................17

4.1 Delivery......................................................................................................................................................17

4.2 Transport to the installation site..................................................................................................................17

4.3 Requirements at the installation site ...........................................................................................................18

4.4 Storage ......................................................................................................................................................19

4.5 Unpacking and installing.............................................................................................................................19

5Assembly and connection............................................................................................................20

5.1 Assembling the linear motor system ............................................................................................................21

5.2 Assembling the moved load.........................................................................................................................22

5.3 Electrical connection...................................................................................................................................22

6Commissioning ..........................................................................................................................29

6.1 Switch on the linear motor system...............................................................................................................29

6.2 Programming..............................................................................................................................................30

7Maintenance and cleaning ...........................................................................................................31

7.1 Linear motor ...............................................................................................................................................33

7.2 Positioning measurement system ................................................................................................................33

7.3 Electromechanical components ...................................................................................................................33

7.4 Linear guideways ........................................................................................................................................33

8Troubleshooting.........................................................................................................................38

9Disposal....................................................................................................................................39

10 Declaration of Incorporation ........................................................................................................40