Copyright HK Instruments 2022 www.hkinstruments. Installaon version 9.0 2022

INSTALLATION

INSTRUCTIONS

CARBON DIOXIDE TRANSMITTERS

CDT2000 Series

• READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING

TO INSTALL, OPERATE OR SERVICE THIS DEVICE.

• Failuretoobservesafetyinformaonandcomplywithinstrucons

canresultinPERSONALINJURY,DEATHAND/ORPROPERTY

DAMAGE.

• Toavoidelectricalshockordamagetoequipment,disconnect

powerbeforeinstallingorservicinganduseonlywiringwith

insulaonratedforfulldeviceoperangvoltage.

• Toavoidpotenalreand/orexplosiondonotuseinpotenally

ammableorexplosiveatmospheres.

• Retaintheseinstruconsforfuturereference.

• Thisproduct,wheninstalled,willbepartofanengineeredsystem

whosespecicaonsandperformancecharacteriscsarenot

designedorcontrolledbyHKInstruments.Reviewapplicaons

andnaonalandlocalcodestoassurethattheinstallaonwill

befunconalandsafe.Useonlyexperiencedandknowledgeable

technicianstoinstallthisdevice.

•Fuseatloadsupply(normally6A,10A,16A)doesnotalwayslimit

therelayoutputloadcurrentto6A.RelayMaximumLoad(250Vx

6Ares.)

•Addanexternalfusetorelaycommonconnector.Useame-lag

fuse(max6A)thatisinaccordancewiththestandardIEC60127-2.

Theproductdoesn’thaveaninternalfusefortherelay.

CAUTION:Theproductmayonlybeconnectedtoovervoltage

categoryIIelectricitynetworkaccordingtoIEC60664-1.

SPECIFICATIONS

ThankyouforchoosinganHKInstrumentsCDT2000seriescarbon

dioxidetransmier.TheCDT2000seriesisintendedforuseincom-

mercialenvironmentsinHVAC/Rapplicaons.

TheCDT2000seriesmeasurescarbondioxide(CO2),ulizingthein-

dustrystandardNDIRmeasurementprinciple,andtemperature(T).

Oponalrelavehumidity(rH)measurementisalsoavailableinthe

samedevice.Eachmeasurementparameter(CO2,rH,T)hasasepa-

rateeldcongurableoutput.

TheCDT2000seriescarbondioxidetransmiersareavailablewith

Modbusconguraon,relayandtouchscreendisplay.

The CDT2000 series transmiers calibrate themselves automa-

callyusingABCTMlogic.TheABCTMlogicrequiresthatthespacein

which the transmier is used needs to to be unoccupied for four

hoursperdaysothattheindoorCO2concentraondropstotheout-

sidelevel.CDT2000-DCisadualchannelmodelwithameasuring

channelandareferencechannelthatmakesaconnuouscompari-

sonandthenecessaryadjustmentaccordingly.CDT2000-DCisalso

suitableforbuildingsthatareconnuouslyoccupied.

•humidityinvariousindustrialapplicaons

•temperaturesinHVAC/Renvironment

•CDT2000-DCseriesdevicescanalsobeusedinapplicaonswhere

thereisaconstantsourceofcarbondioxidepresent(forexample

hospitalsandgreenhouses)

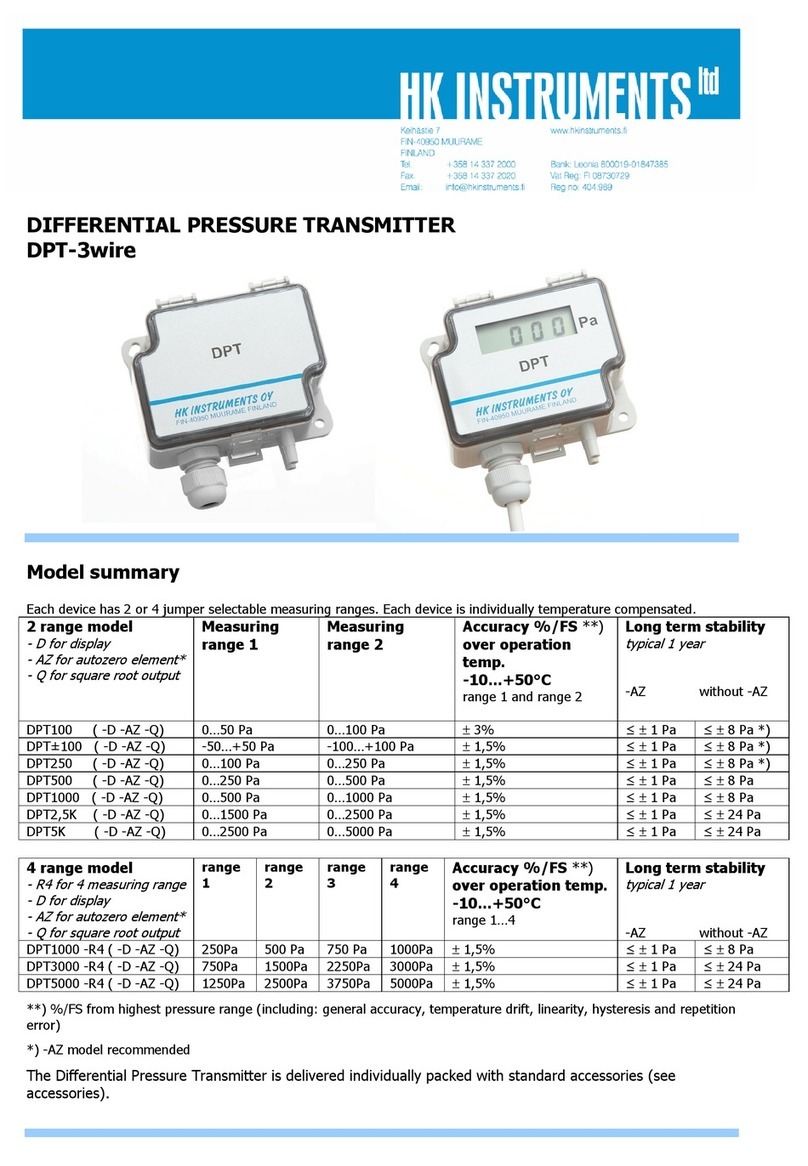

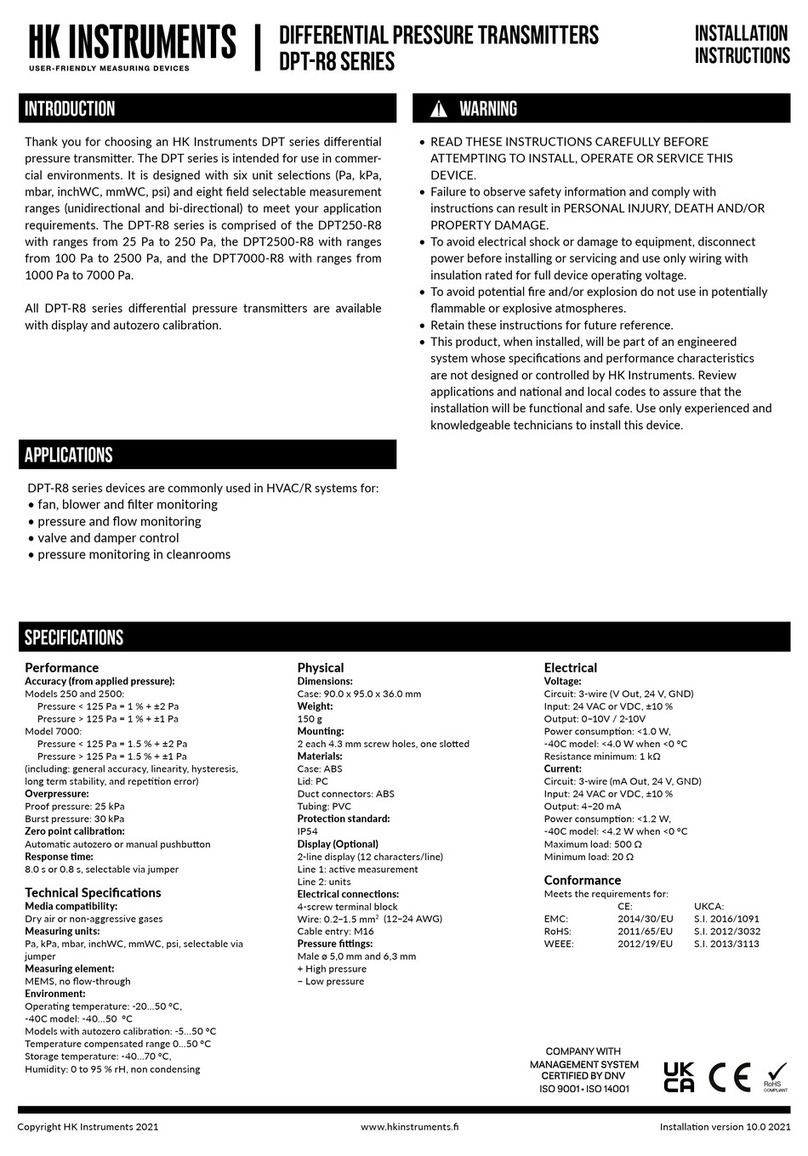

SPECIFICATIONS

Performance

Measurement ranges:

CO2:400–2000ppm

Temperature:0...50°C

Relavehumidity:0–100%

Accuracy:

CO2:±40ppm+3%ofreading,DCmodel:75ppmor

10%ofreading(whicheverisgreater)

Temperature:<0.5ºC

Relavehumidity:±2...3%at0...50°Cand10–90%rH

Totalerrorbandincludesaccuracy,hysteresisand

temperatureeectover5...50°Cand10–90%rH.

Technical Specicaons

Media compability:

Dryairornon-aggressivegases

Measuring units:

ppm,°Cand%rH

Measuring element:

CO2:Non-dispersiveinfrared(NDIR)

Temperature: Pt1000(modelswithoutrH-measurement

Integrated(modelswithrH-measurement)

Relavehumidity:Thermosetpolymercapacive

sensingelement

Calibraon:

Automacself-calibraonABCLogicTMorconnuous

comparison(DC)

Environment:

Operangtemperature:0...50°C

Storagetemperature:-20...70°C

Humidity:0to95%rH,noncondensing

Physical

Dimensions:

Case:99x90x32mm

Weight:

150g

Mounng:

3screwholessloed,3.8mm

Materials:

Case: ABS

Protecon standard:

IP20

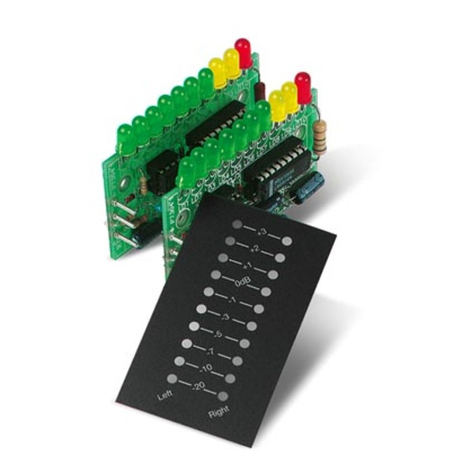

Display (Oponal)

Touchscreen

Size:77.4x52.4mm

Electrical connecons:

Powersupply:

5-screwterminalblock

(24V,GND,CO2,rH,T)

0.2–1.5mm2(16–24AWG)

Relay out:

3-screwterminalblock

(NC,COM,NO)

0.2–1.5mm2(16–24AWG)

Electrical

Input: 24VACorVDC,±10%

Currentconsumpon:max90mA(at24V)+

10mAforeachvoltageoutputor20mAfor

eachcurrentoutput

Outputsignal(CO2,rH,temperature):

0–10V,R>1kΩ

2–10V,R>1kΩ(oponalvoltageoutput,displayrequired)

4–20mA,R<500Ω

Relay out:

SPDTRelay,250VAC/30VDC/6A

Adjustableswitchingpointandhysteresis

Conformance

Meetsrequirementsfor:

CE: UKCA:

EMC: 2014/30/EU S.I.2016/1091

RoHS: 2011/65/EU S.I.2012/3032

LVD/EESR: 2014/35/EU S.I.2016/1101

WEEE: 2012/19/EU S.I.2013/3113

INTRODUCTION

APPLICATIONS

WARNING

CDTseriesdevicesarecommonlyusedtomonitor:

• CO2andhumiditylevelsinoces,publicspaces,meengrooms

andclassrooms

• CO2levelsofreturnairinvenlaonsystems

•incomingairandreturnairhumiditylevelsinvenlaonsystem

RoHS

COMPLIANT