HK Instruments DPT-R8 Series User manual

Thank you for choosing an HK Instruments DPT Series Differential

Pressure Transducer. The DPT Series is intended for use in commercial

environments. It is designed with four unit selections (inWC, mmWC, Pa,

mbar) and eight eld selectable measumerement ranges (Unidirectional

and Bi-directional) to meet your job measurement requirements. The

DPT-R8 Series Differential Pressure Transducers is comprised of the

DPT1-R8 with ranges from 0.1 to 1.0 inWC, the DPT10-R8 with ranges

from 0.5 to 10.0 inWC, and the DPT30-R8 with ranges 10.0 to 30.0 inWC.

All DPT-R8 Series Differential Pressure Transducers are available with

display, and NIST standard calibration certicates.

APPLICATIONS

DPT-R8 series devices are commonly used in

HVAC/R systems for:

• fan, blower and filter monitoring

• pressure and flow monitoring

• valve and damper control

• pressure monitoring in clean rooms

Copyright HK Instruments Installation Version 1.0 2012

DIFFERENTIAL PRESSURE TRANDUCERS - AIR

DPT1-R8 / DPT10-R8 / DPT30-R8

INTRODUCTION WARNING

INSTALLATION

INSTRUCTIONS

●READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING

TO INSTALL, OPERATE OR SERVICE THIS DEVICE.

●Failure to observe safety information and comply with instructions could

result in PERSONAL INJURY, DEATH AND/OR PROPERTY DAMAGE.

●To avoid electrical shock or damage to equipment, disconnect power

before installing or servicing and use only wiring with insulation rated for

full device operating voltage.

●To avoid potential re and/or explosion do not use in potentially

flammable or explosive atmospheres.

●Retain these instructions for future reference.

●This product, when installed, will be part of an engineered system whose

specications and performance characteristics are not designed or

controlled by HK Instruments, Inc. Review applications and national an

local codes to assure that the installation will be functional and safe. Use

only experienced, knowledgeable, technicians to install this device.

SPECIFICATIONS

Performance

Accuracy (at applied pressure):

Ranges < 0.5 inWC = ±0.01 inWC

Ranges ≥ 0.5 inWC = ±1.5% inWC

Accuracy specications include: general accuracy, temperature drift, linearity,

hysteresis, long term stability, and repetition error).

Thermal Effects:

Temperature compensated across the Full Spectrum of capability.

Overpressure:

Proof Pressure: 100 inWC

Burst Pressure: 120 inWC

Zero Point Calibration:

Automatic with circuit or Manual pushbutton Auto-Zero

Response Time:

4.0 sec or 0.8 sec, selectable via jumper

Technical Specications

Media Compatibility:

Dry air or non-aggressive gases

Measuring units:

Pa, mbar, inWC, mmWC, selectable via jumper

Measuring element:

Piezoresistive

Environment:

Operating Temperature: 14 -122°F (-10 - 50°C)

Storage Temperature: -4 - 158°F (-20 - 70°C)

Humidity: 0 to 95% RH, non condensing

Physical

Case:

Dimensions: 3.54” x 3.74” x 1.4” (90.0 x 95.0 x 36.0 mm)

Weight: 5.3 oz (150 g)

Mounting: 2 each 0.1875” (4.3mm) screw holes, one slotted

Materials: Case: ABS (UL 94 V-0 Approved)

Lid: PC (UL 94 V-0 Approved)

Protection standard: IP54 / NEMA3

Display (Optional)

3 1/2 Digit LCD Backlit Display

2-Line Display (12 character/line)

Line 1: Active Measurement

Line 2: Units

Size: 1.81” x 0.57”

Electrical Connections:

4 screw terminal block

Wire: 12-24AWG (0.2 – 1.5 mm)

Cable Entry:

Strain Relief: M16

Knockout : 0.625” (16mm)

Pressure Fittings:

3/16” (5.2mm) barbed brass

+ High pressure

− Low pressure

Electrical

Voltage:

Circuit: 3-wire (V Out, 24V, GND)

Input: 24VAC or VDC, ±10%

Output: 0-5V or 0-10V, selectable via jumper

Power Consumption: <1.0W

Resistance Minimum: 1k

Current:

Circuit: 3-wire (mA Out, 24V, GND)

Input: 24VAC or VDC, ±10%

Output: 4-20 mA, selectable via jumper

Power Consumption: <1.2W

Maximum load: 500

Conformance

Meets requirements for CE marking:

EMC directive 2004/108/EY

RoHS Directive 2002/95/EY

Meets safety requirements for electrical equipment for measurement, control,

and laboratory use:

ETL marking, standard IEC61010-1

Product is tested and meets the NRTL product-approval requirements.

Copyright HK Instruments Installation Version 1.0 2012

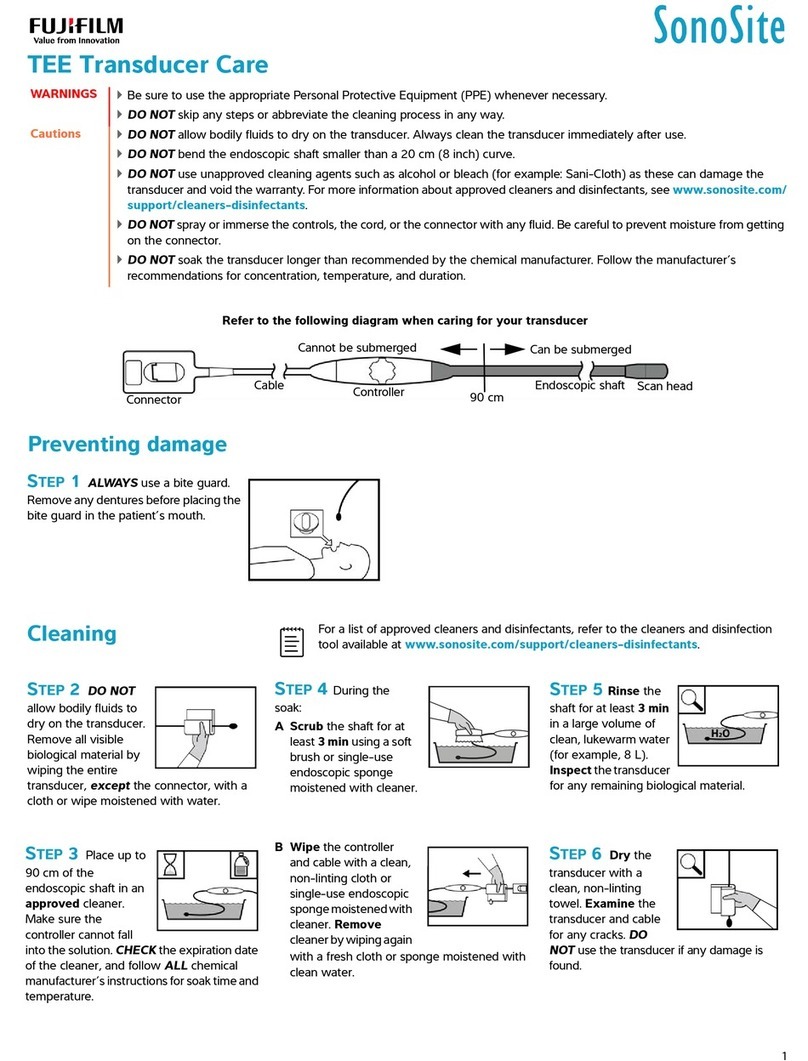

SCHEMATICS

MOUNTING THE DEVICE

INSTALLATION

STEP 1

1) Select mounting location (duct, wall, panel)

2) Use the device as a template and mark the screw holes

3) Mount with appropriate screws (not included)

YES NO NO

Figure 3b - Mounting Orientation

3.54

(90.0)

3.03

(77.0)

2.815

(71.5)

2.086

(53.0)

0.169

(4.2)

3.74

(95.0)

1.41

(36.0)

in

(mm)

Pressure Sensor

Zero Button Connection for

optional display

Terminal Block

LED

Jumpers

1) Mount the device in desired location (see step 1)

2) Open lid and route cable through strain relief and connect wires to

terminal block (see step 2)

3) Device is now ready for conguration

WARNING! Apply power after the device is properly wired.

Figure 3a - Surface Mounting

DIMENSIONAL DRAWINGS

Figure 3c - Application Connections

Static Pressure Filter/Damper

Monitoring

Fan/Blower

Monitoring

Not

Connected

Copyright HK Instruments Installation Version 1.0 2012

SELECTING RESPONSE TIME

The response time affects how fast the transducer reacts to

changes in the system. Response time is the time the device takes

to reach half of the change in the measured value. To smooth out

unstable pressure uctuations in airow applications, select longer

response time.

Example:

Selected response time: 4.0 seconds

Selected measurement unit: inWC

Change in the system: increase of ∆P1= 2

Result: Output signal = ∆P2= 1, in 4.0 seconds after the change in

the system (½ ∆P1= ∆P2= 1).

To change response time, install or remove jumper on J4 (see

gure 5)

1) Install jumper on J4 for 4.0 Second response time.

2) Remove jumper from J4 for 0.8 Second response time.

CONFIGURATION

1) Select the desired measurement unit (see step 3)

2) Select the desired measurement range (see step 4)

3) Select the desired response time (see step 5)

4) Zero the device (see step 6)

5) Connect pressure tubes. Connect postive pressure to port

labeled “+” and negative pressure port to “-”

6) Close the lid. The device is ready to use.

SELECTING MEASUREMENT UNIT

1) To change the measurement unit appearing on the display, install

a Jumper to both pins of J5 (See gure 5)

2) Push down the zero button (joystick) and the measurement unit

options (inWC, mmWC, Pa, mbar) will cycle on the display.

3) To select a unit option to display, remove the jumper from J5

while the measurement unit is visible in the display.

STEP 3

SELECTING THE MEASUREMENT RANGE

1. Determine Range Number.

a. Find Model # in Chart 1.

b. Find Measurement Unit (selected in Step 3), in the left

column, under applicable Model #.

c. Find required Measurement Range on the same line as the

Measurement Unit (b above) and determine Range Number

in the header.

2. Install jumpers on J1, J2, and J3 as required.

a. Using the Range Number from 1c above, nd corresponing

Range Number in Chart 2.

b. Install jumpers on J1, J2, and J3 on device, as shown

under the Range Number in Chart 2. (Grey color indicates

that a jumper is installed. Reference Figure 5 for jumper

installation)

Range 1 Range 2 Range 3 Range 4 Range 5 Range 6 Range 7 Range 8

inWC

Pa

mbar

mmWC

-0.1-0.1

-25-25

-0.25-0.25

-2.5-2.5

-0.25-0.25

-62-62

-0.62-0.62

-6.4-6.4

-0.5-0.5

-125-125

-1.25-1.25

-12.7-12.7

-1.0-1.0

-250-250

-2.5-2.5

-25.4-25.4

0-0.1

0-25

0-0.25

0-2.5

0-0.25

0-62

0-0.62

0-6.4

0-0.5

0-125

0-1.25

0-12.7

0-1.0

0-250

0-2.5

0-25.4

Model# DPT1-R8

Model# DPT10-R8

Range 1 Range 2 Range 3 Range 4 Range 5 Range 6 Range 7 Range 8

inWC

Pa

mbar

mmWC

-0.5-0.5

-125-125

-1.25-1.25

-12.7-12.7

-2.5-2.5

-622-622

-6.2-6.2

-64-64

-5.0-5.0

-1250-1250

-12.5-12.5

-127-127

0-0.5

0-125

0-1.25

0-12.7

0-1.0

0-250

0-2.5

0-25.4

0-2.5

0-622

0-6.2

0-64

0-5.0

0-1250

0-12.5

0-127

0-10.0

0-2500

0-25

0-254

FIGURE 3

For CE compliance, a properly grounded shielding cable is

required.

1) Unscrew strain relief and route cable.

2) Connect the wires as shown in gure 4a or 4b.

3) Tighten the strain relief.

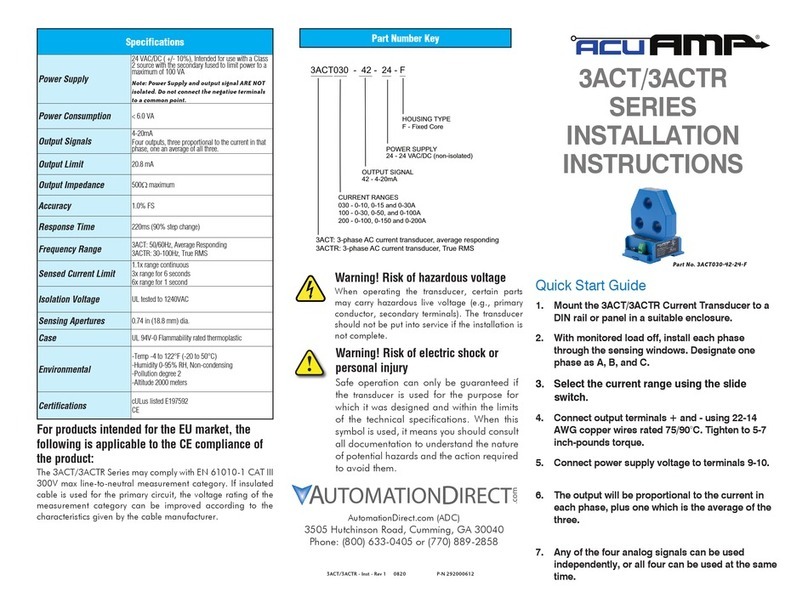

WIRING DIAGRAMS STEP 2

V

0-10V

Not Used

24V

GND

+ Power Supply

24VDC / 24VAC

A

Not Used

4-20mA

24V

GND

+ Power Supply

24VDC / 24VAC

STEP 4

STEP 5

Figure 4a - Wiring Diagram 0-10V Output

Figure 4b - Wiring Diagram 4-20mA Output

Chart 1

Model# DPT30-R8

inWC

Pa

mbar

mmWC

-5.0-5.0

-1250-1250

-12.5-12.5

-127-127

-10.0-10.0

-2500-2500

-25-25

-254-254

-15.0-15.0

-3750-3750

-37.5-37.5

-380-380

0-10

0-2500

0-25

0-254

0-15

0-3750

0-37.5

0-380

0-20

0-5000

0-50

0-508

0-25

0-6250

0-62.5

0-635

0-30

0-7500

0-75

0-762

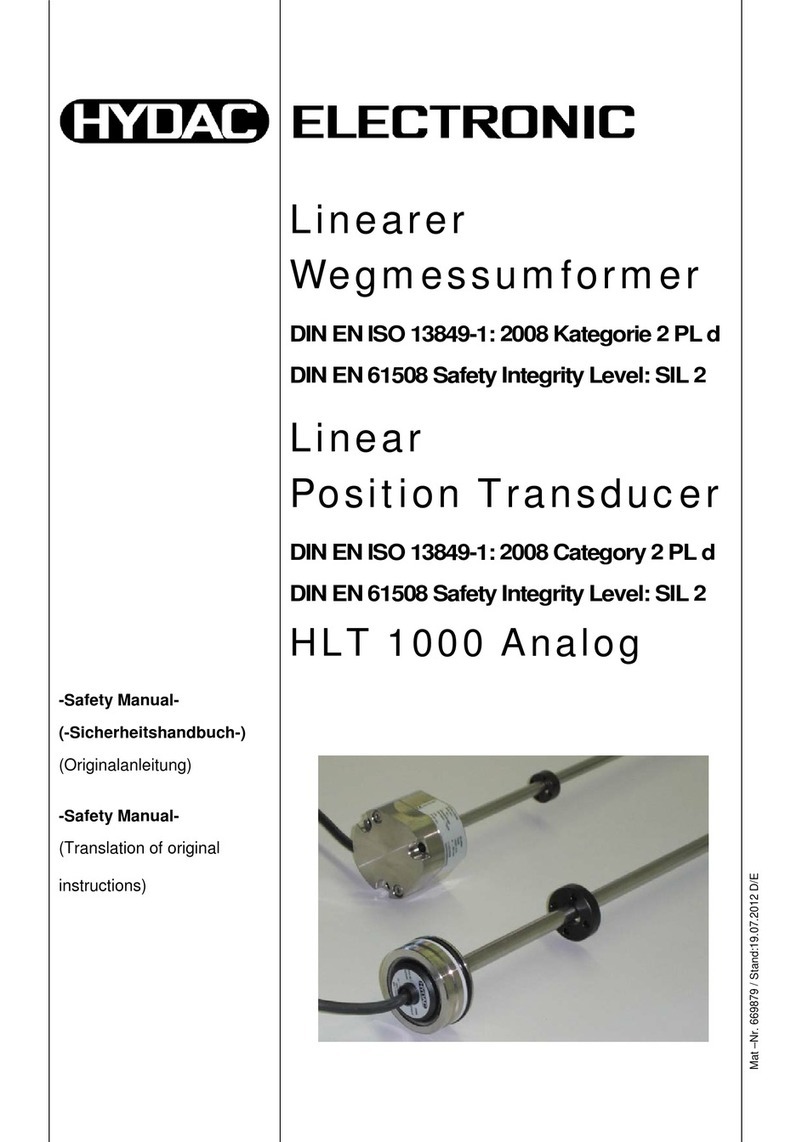

Range 1 Range 2 Range 3 Range 4 Range 5 Range 6 Range 7 Range 8

Range 7 Range 8Range 1 Range 2 Range 3 Range 4 Range 5 Range 6

Jumper J1

Jumper J2

Jumper J3

Chart 2

(Grey color indicates that a jumper is installed. Reference Figure 5 for jumper installation)

Figure 5 - Jumper Installation

No Jumper

Circuit Open

Jumper StoredJumper Installed

Cicuit Closed

(Grey color indicates that a jumper is installed)

Copyright HK Instruments Installation Version 1.0 2012

ZERO THE DEVICE STEP 6

a) Disconnect both pressure tubes from the pressure ports labeled

+ and –.

b) Push down the zero button (joystick) until the LED light (red)

turns on and the display reads “zeroing” (display option only). (see

Figure 6)

c) The zeroing of the device will proceed automatically. Zeroing is

complete when the LED turns off, and the display reads 0 (display

option only).

d) Reinstall the pressure tubes, ensuring the High pressure tube is

connected to the port labeled +, and the Low pressure tube is

connected to the port labeled −.

NOTE: The zero point should be calibrated via manual auto zero,

one hour after installation and at least every 12 months during

normal operations.

2) function

If the device includes the optional e-zero circuit, no action is

required.

(-AZ) is a True Auto Zero function in the form of an

automatic zeroing circuit built into the PCB board. The

function electronically adjusts the transducer zero at predeter-

mined time intervals (every 10 minutes). The function

eliminates all output signal drift due to thermal, electronic or

mechanical effects, as well as the need for technicians to remove

high and low pressure tubes when performing initial or periodic

transducer zero point calibration. The adjustment takes 4

seconds after which the device returns to its normal measuring

mode. During the 4 second adjustment period, the output and

display values will freeze to the latest measured value.

Transducers equiped with the function are virtually

maintenance free.

To zero the device two options are available:

1) Manuel Pushbutton Auto Zero

2) zero point calibration function

Does my transducer have an function?

See the product label. If it shows –AZ in the model number, then you

have the function.

1) Manual Pushbutton Auto Zero

NOTE: Supply voltage must be connected at least one hour prior to

zero point adjustment.

Figure 6 - Zeroing

Press Down Button

LED turns ON

Display reads “Zeroing”

LED

FIGURE 3WARRANTY POLICY

(a) WARRANTY COVERAGE: HK warrants to the original end user

of the Products that the Products will, at the date of initial

purchase, meet the applicable specication for such Products (as

described by HK in its product literature) and, under normal use

and service, will be free from any defects in materials or manufac-

ture for (a) one (1) year from date of sale to end user for electrome-

chanical Products and (b) ve (5) years from date of manufacture

for electronic Products.

(b) NO WARRANTY OF PRODUCT SUITABILITY: Neither HK nor

the manufacturer of the Products to be sold hereunder

(“Manufacturer”) makes any warranty that Products are suitable for

a particular purpose, application or design. Many states and

localities have differing codes or regulations governing the installa-

tion and/or use of HK products. HK does not guarantee compli-

ance with such codes or regulations; the end user is solely

responsible for safe and correct installation and use of the Prod-

ucts and for compliance with such codes and regulations.

(c) EXCLUSION OF IMPLIED WARRANTIES: THE WARRANTY

HEREIN IS THE ONLY WARRANTY APPLICABLE TO THE PROD-

UCTS AND EXCLUDES ALL OTHER WARRANTIES, INCLUDING

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, AND ANY IMPLIED WARRANTY ARIS-

ING FROM COURSE OF DEALING OR USAGE OF TRADE.

(d) REMEDIES FOR NON-CONFORMITY OR BREACH OF WAR-

RANTY: If the Product purchased does not conform to the appli-

cable warranty, HK will provide, at its option, one of the following

remedies: (1) repair of the non-conforming Product, (2) replace-

ment with a conforming Product, or (3) refund of the original

purchase price. THESE REMEDIES SHALL BE THE EXCLUSIVE

AND SOLE REMEDY for any breach of warranty. HK and Manufac-

turer have no other responsibility or liability for breach of warranty

or otherwise.

(e) LIMITATION OF LIABILITY: NEITHER HK NOR MANUFAC-

TURER WILL BE LIABLE FOR ANY INCIDENTAL, SPECIAL,

INDIRECT, OR CONSEQUENTIAL DAMAGES UNDER ANY

CIRCUMSTANCE, INCLUDING WITHOUT LIMITATION ANY

DEFECT IN THE PRODUCT PURCHASED.

(f) FURTHER LIMITATIONS: The warranty herein does not cover

damage caused by lightning, ood or other natural phenomenon;

normal wear and tear; accident, improper or careless handling,

abnormal use, overloading, improper storage or abuse; incorrect

installation, care or reconstruction; or alteration, calibration,

reconguration, maintenance or installation work done by unquali-

ed personnel. Should Manufacturer alter the structure of any

Product in the future, HK and Manufacturer shall not be obligated

to make comparable changes to Products already purchased. HK

will give a new warranty for Products being replaced or repaired

within the warranty period, however only to the expiration of the

original Product’s warranty period. The warranty includes the repair

of a defective part or device, or if needed, a new part or device,

but no other costs except as otherwise stated in the HK Distributor

Terms and Conditions.

This manual suits for next models

3

Other HK Instruments Transducer manuals