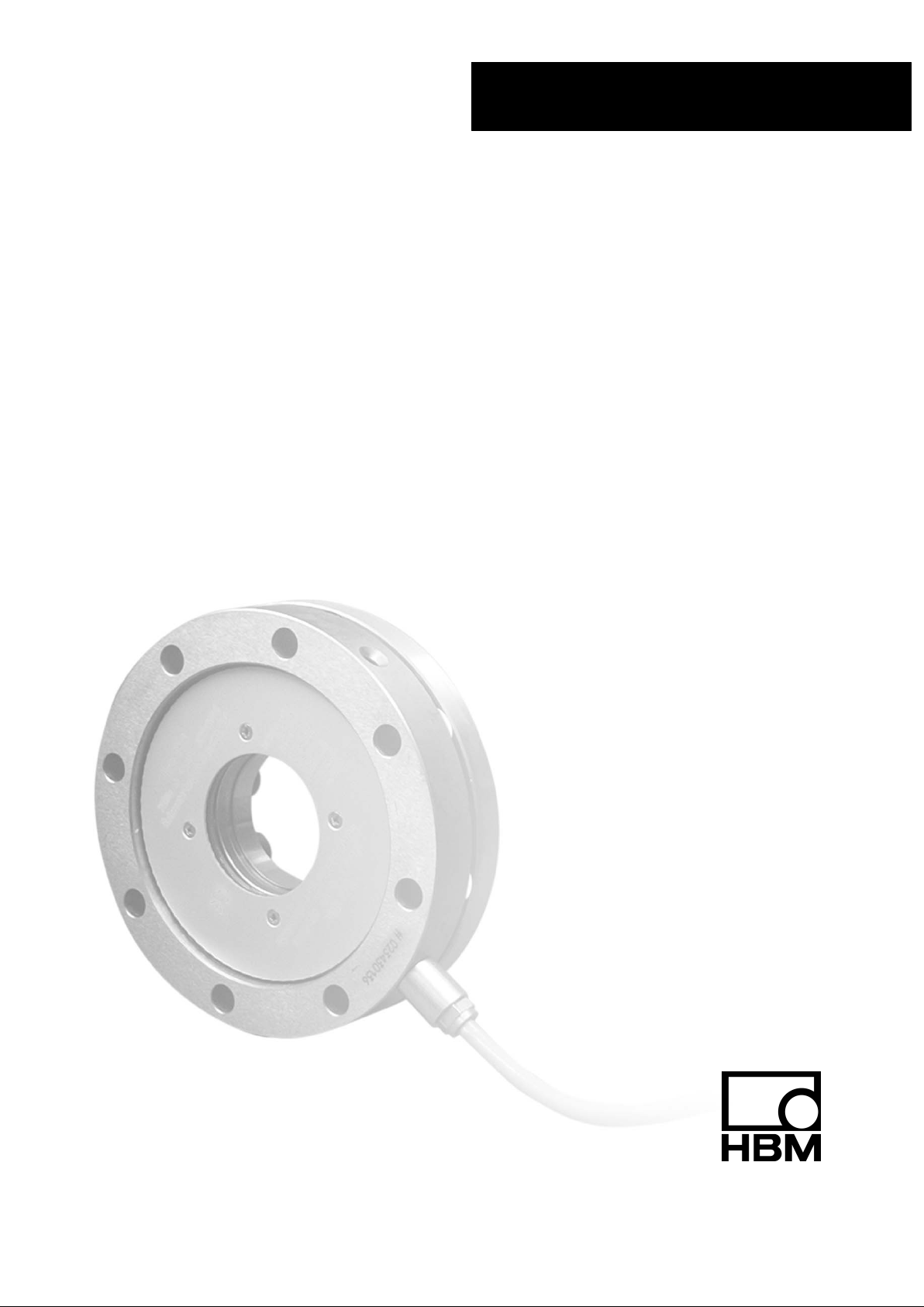

8TB1A

HBM A01627.0en/de/fr

1 Scope of supply

The scope of supply includes the following:

1Reference torque measuringdisc

1 Mounting Instructions

1 Test record

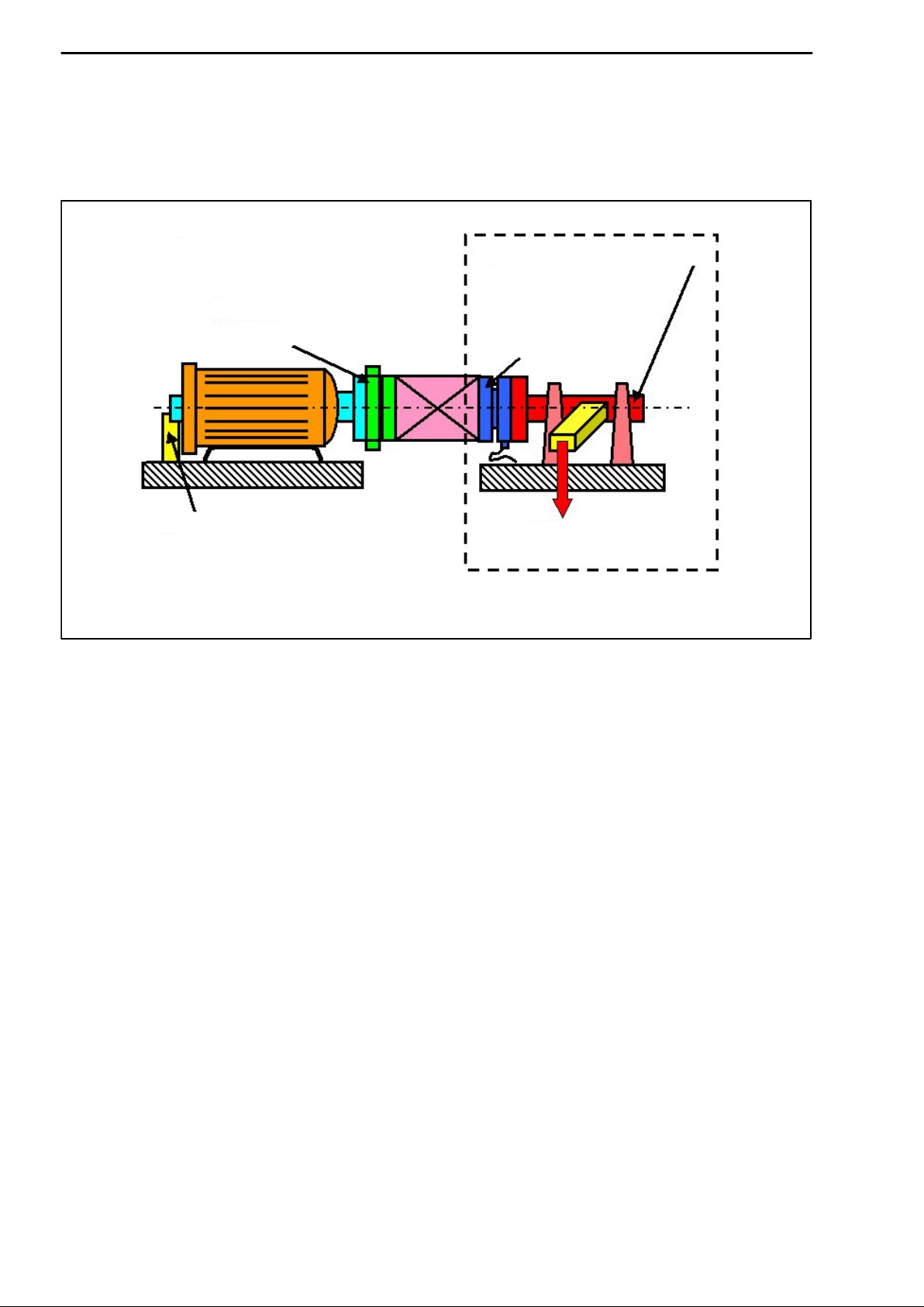

2Application

Transducers measure static and dynamic torques in nonturning mode. The

nominal torques fall within the range 100 N⋅m to 10kN⋅m.

Transfertorque transducer

The main applications are torque transfer, for example, when calibrating

reference transducers in test and calibration machines and comparisons of

the reference normals of various calibration laboratories.

In the case of transfer transducers, a high degree of comparability is import

ant, as when relaying torque, this provides a gage for various observers, test

conditions, laboratories and the installation and time situation. So for relay, the

same installation conditions should be created as for calibration in the refe

rence normal, or relevant adapters (for recommendations, see Page 17f)

should be included in the calibration.

Reference torque transducer

Reference torque transducers are mounted in a calibration device and then

the entire calibration machine is qualified or certified by means of transfer

torque transducers, for example. The precise sensitivity of the transducer is

thus less important.

General torque measurements in nonturning mode

Because of the high mechanical loading capacity, the permissible vibration

bandwidth of 160% (10kN⋅m=120%) of nominal torque and the compact

design, the transducers are also eminently suitable for use in testing

machines for component testing (rotary alternating stress) or as reaction

torque transducers, for example in agitators with direct drive motor or gearbox

connection.