HM Digital PS-202 User manual

PS-202 05/05

WARRANTY

ONE YEAR LIMITED WARRANTY

HM Digital, Inc. ("the Company") products are warranted to the purchaser against defective

materials and workmanship for three (3) year from the date of purchase.

What is covered:Repair parts and labor, or replacement at the Company's option.

Transportation charges for repaired of new product to be returned to the purchaser.

What is not covered:Transportation charges for the defective product to be sent to the

Company. Any consequential damages, incidental damages, or incidental expenses, including

damages to property. This includes damages from abuse or improper maintenance such as

tampering, wear and tear, water damage, or any other physical damage. The Company's

products are not waterproof and should not be fully submerged in water. Products with any

evidence of such damage will not be repaired or replaced. See additional note below.

How to obtain warranty performance:Attach to the product your name, address, description

of problem, phone number, and proof of date of purchase, package and return to:

HM Digital, Inc.

5819 Uplander Way

Culver City, CA 90230

Implied Warranties:Any implied warranties, including implied warranties of merchantability and

fitness for a particular purpose, are limited in duration to five years from date of purchase. Some

states do not allow limitations on how long an implied warranty lasts, so the above limitation may

not apply to you. To the extent any provision of this warranty is prohibited by federal and state

law and cannot be preempted, it shall not be applicable. This warranty gives you specific legal

rights, and you may also have other rights, which vary from state to state.

NOTE: Warranties are product-specific. Third-party products and products deemed by HM

Digital as "accessories" are not covered under warranty. Third-party products include, but are

not limited to, batteries and fittings. Accessories include, but are not limited to, precipitator rods,

fuses and product cases.

This manual and all information contained herein copyright HM Digital, Inc.

An extended version of this manual can be downloaded at

www.tdsmeter.com/products/usersguideps202.pdf

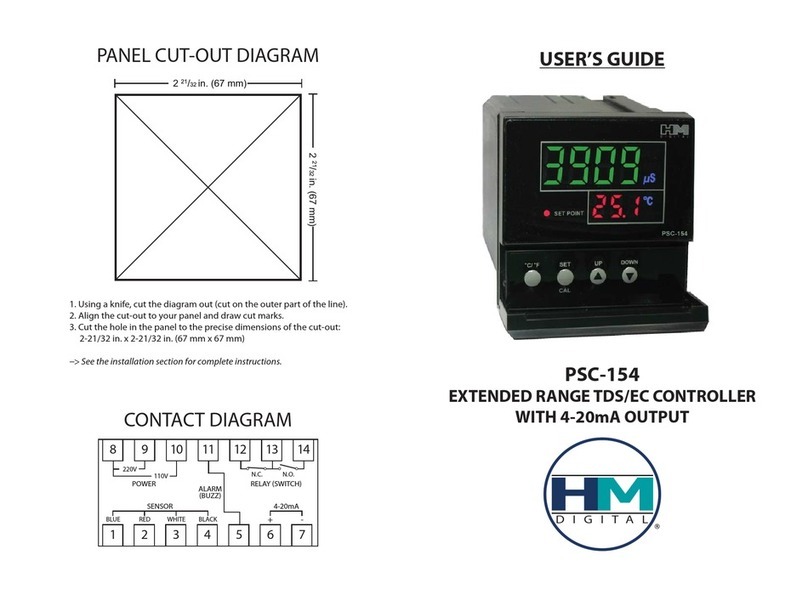

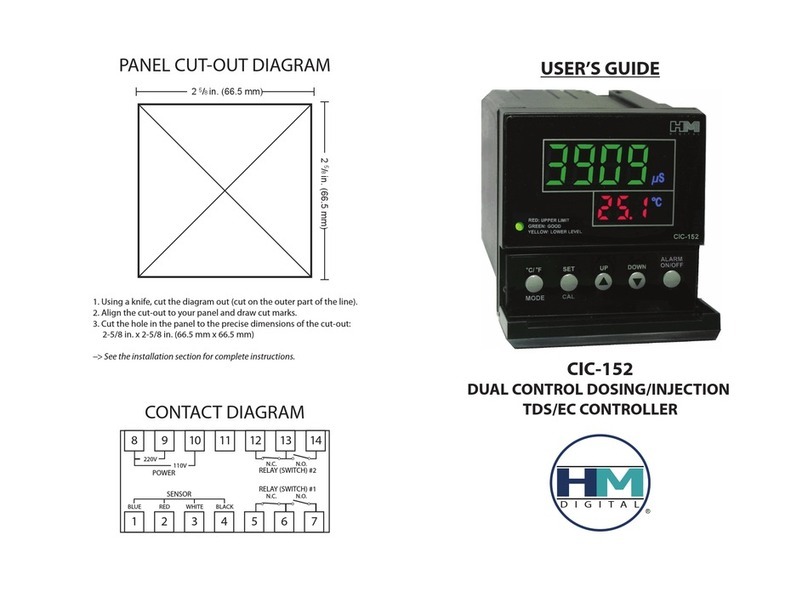

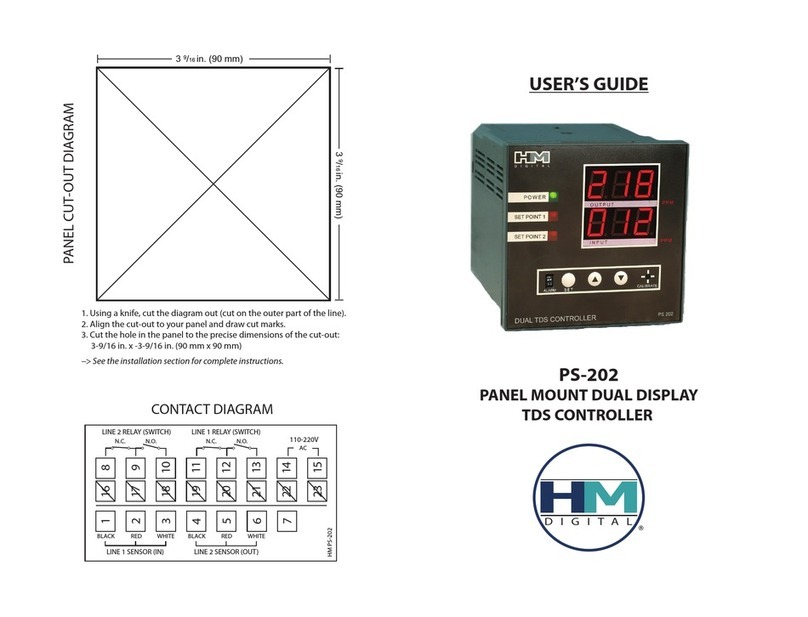

USER’S GUIDE

PS-202

DUAL DISPLAY TDS CONTROLLER

PS-202 05/05

OVERVIEW

Thank you for purchasing HM Digital’s PS-202. The PS-202 is a TDS (Total Dissolved Solids)

controller that monitors and controls the TDS levels of two water lines. If the TDS levelsof either

line reach the user-determined set-points, the controller will send an analog signal (via relay

switch) to stop a valve or pump and sound an optional alarm.

CONTACT INFORMATION

If you have any problems or questions regarding your meter, please contact HM Digital, Inc.

5819 Uplander Way www.tdsmeter.com

Culver City, CA 90230 1-800-383-2777

SPECIFICATIONS

TDS Range:0 -999 ppm

Resolution: 1 ppm

Accuracy:+/-2% F.S.

Temperature Compensation:Automatic (ATC) (1-65o Celsius)

Calibration:Manually adjustable (factory calibrated at 342 ppm NaCl)

Set-Point:Controlled by on-screen up/down buttons

Relay Control:The unit will send an analog signal to a pump/valve when the TDS levels of

either line reach the set point

Alarm:Steady beep when the set point for either line is reached

Probe:½” bushing, 3 meter (9.8 ft) shielded cable)

Display: Bright 5/8” L.E.D. dual displays

Power supply:AC 110V / AC 220V

Dimensions:9.4 x 9.4 x 12.5 cm (3.7 x 3.7 x 4.9 in.)

Monitor Weight:569.8 grams (1 lb 4.1 oz)

BOX CONTENTS

1. Controller

2. Sensor (2)

3. Sensor cable (gray) (2)

4. Power cord (black)

5. Mounting brackets

INSTALLATION INSTRUCTIONS

1. Remove the contents from the box.

2. View the diagram on the backof the controller.

3. Connect the black power cord to the outputs numbered 14 and 15. Screw in tight with a

Phillips head screwdriver. It does not matter which color wire is connected to the outputs. (Note

–If in the United States, connect the plug adapter to the power cord).

4. Connect agray sensor cable by attaching the blackwire to output #1, the red to #2 and the

white to #3. This is your output line (line 1). The output isthe top reading.

5. Connect the second gray sensor cable by attaching the blackwire to output #4, the red to

output #5, and the white to output #6. This is your input line (line 2).

6. Align the pins ofeachsensor to its cable and attach. Screw the tightening ringsclosed.

7. If the pump relay switch is already on, connect the pump relay cord (not included) for the IN

relay to outputs #9 and #10. Connect the pump relay cord for the OUT relay to outputs #12 and

#13.

8. Insert the mounting brackets into the grooves on the bottom and top of the controller. Fasten

the brackets with the included screws.

9. Mount the controller to the panel.

10. Insert the sensor electrodesinto ½” T-fittings, respectively for the output and input lines.

11.Plug the power cord into an electrical outlet.

USAGE INSTRUCTIONS

1. The controller will turn on when the power cord is plugged into an electrical outlet.

2. The controller comes factory calibrated to a 342 ppm NaCl solution. If you wish to recalibrate,

you can do so by inserting a screwdriver into the calibration trimmer pot. Turning clockwise will

increase the reading; turning counter-clockwise will decrease the reading. Calibration must be

done simultaneously for both lines.

3. To adjust the set point for the output line, press the ‘SET’ button. The reading will flash on the

display. Use the UP and DOWN buttons to adjust the reading. Pressing the button will advance

the reading by a single digit. Holding the button down will advance the reading quickly.

4. When the reading is at the desired set point, press the ‘SET’ button again. This will save the

set point and switch to the input line. Change the set point for the input line using the arrow

buttons. Pressing the ‘SET’ button again will save the setting for the input line and return to

controller/monitor mode. If you do not wish to change the input line set point, simply press the

‘SET’ button again, without pressing the arrow buttons.

5. If the TDS levels of either line reach the saved set point, the controller will send an analog

signal (via a relay switch) to the pump or valve that is attached to the in relay or out relay.

6. To turn off the controller, unplug it from the electrical outlet.

NOTE: It is advisable to test the set pointsand relay controlsprior to installing it on a water line.

Cleaning:

To clean the electrodes, use rubbing alcohol and a cotton swab. Lightly clean the electrodes.

Rinse with DI or distilled water. Air dry.

Electrode Replacement:

If your electrode has been damaged, you can purchase a new one without having to purchase a

new controller. Contact HM Digital or your authorized HM Digital distributor.

Other HM Digital Controllers manuals

Popular Controllers manuals by other brands

Lutron Electronics

Lutron Electronics Hi-lume Premier manual

cyber Switching

cyber Switching EV-Master 7700 Series user manual

Westinghouse

Westinghouse 77886 Installation & operating instructions

K-Circle

K-Circle Base Module instruction manual

Asco

Asco 643 Series Installation and maintenance instructions

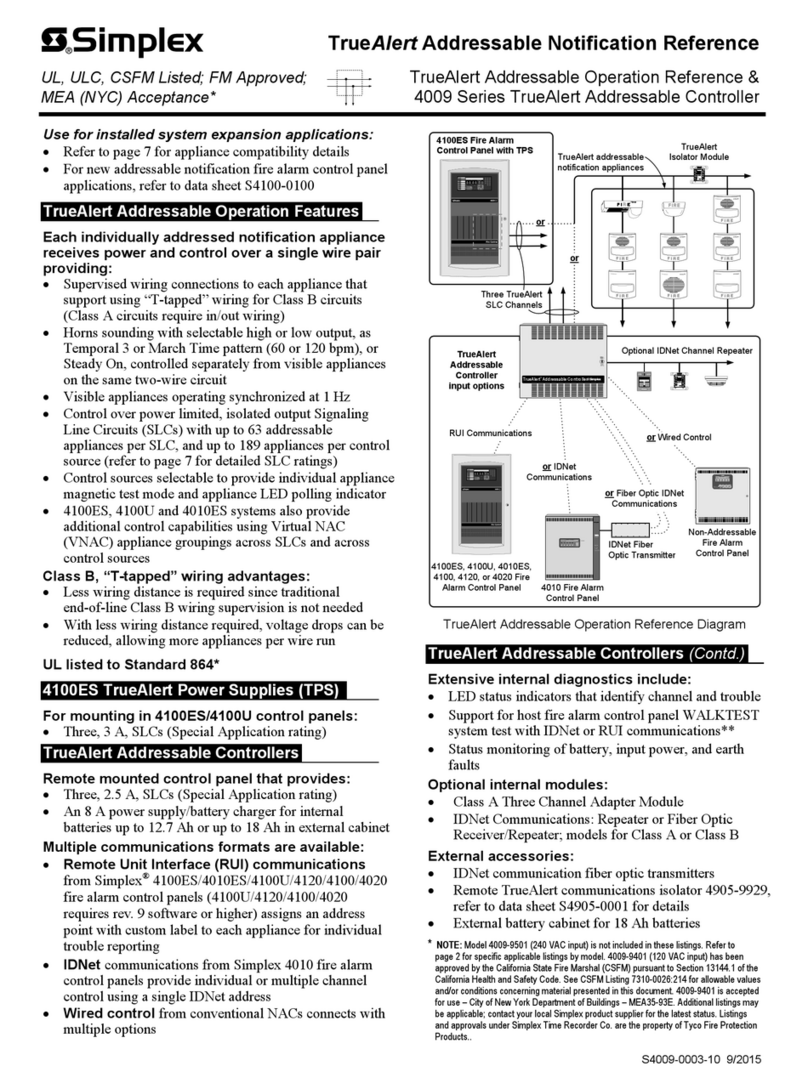

Simplex

Simplex TrueAlert 4009 Series Operation reference