HMC Trainer 5008 User manual

Note:

Before installaon and operaon, please read this operaon manual carefully and

save this manual for future reference.

te:

HARDCORE TRAINING

Safety Instrucons

Parts List

Hardware & Tool List

Overview Drawing

Assembly

How to Use

Warm Up

Trouble Shoot & Main Tenance

Contents

2

3

4

6

7

14

13

12

3

Read all the instrucons in this manual and do warm up exercises beforeusing this

equipment.

Before using this equipment, please consult your physician for a complete physical

examinaon. If you feel any discomfort while exercising, please stop immediately and

consult your doctor.

Before exercising and to avoid injuring your muscles, perform warm-up exercise for each

muscle group is highly recommended. Please refer to Warm Up secon of the Owner’s

Manual.

Keep the equipment indoors, away from moisture and dust. Place the equipment on a

level surface, with a mat beneath it to protect the floor or carpet. Make sure that there

is enough clearance around the equipment to mount, dismount, and use it.

Inspect and properly ghten all parts regularly. Replace any worn parts immediately.

Ensure that your fingers or clothing do not catch in the equipment moving parts.

Please keep children and pets away from the equipment at all mes. It is only suitable

for adults.

The equipment should not be used by persons weighng more than 150 kg. Serious

injury may occur if the user’s weight exceeds the limit shown here.

If you hear unusual noise when exercising, please stop your training immediately.

Do not use the equipment unl the problem has been resolved.

To prevent injuring you when stop exercising, do not touch the flywheel immediately.

Safety Instrucons

4

noitpircseD.oNnoitpircseD.oN

cp1L-revoccitsalptengaML62cp1emarFniaM1

2 Front stabilizer bar 40x80x2T 1 pc 27 Support bar 20x20x1.4T 1 pc

cp1tekcarbtengaM82cp1T2x08x04rabrezilibatsraeR3

4 Upright post 40x80x2T 1 pc 29 Tension control bar 1 pc

cp1revocdexiF03cp1T2x08x04tsoptaeS5

6 Handlebar Φ25.4x2T 1 pc 31 Пcp2renetsafepahs

cp1rehsawgnirpS23cp1tekcarbgnivomraeS7

CP26MtunnolyN33cp2lmm001x001x05renetsafictsalP8

CP28MtunnolyN43cp10016-LVtaeS9

10 Flywheel Φcp401MtunpaC53cp1864

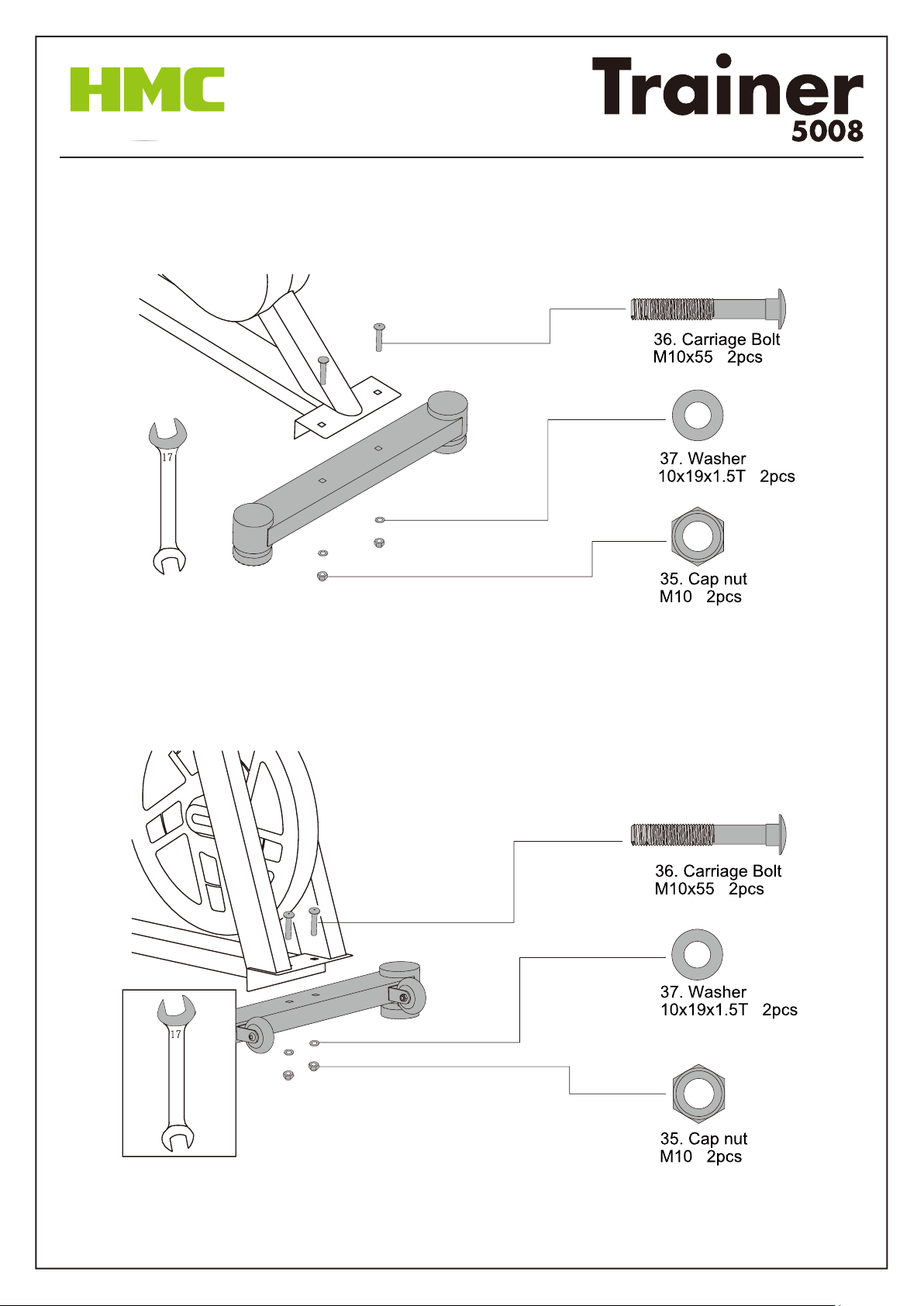

11 Belt wheel Φ260 with Axis 1 pc 36 Carriage bolt M10x55 4 pc

CP6T5.1x91x01rehsaW73c

p15KP0951tleB21

cp4T6x01MtuN.xeH83cp1R-revocniahcniaM31

14 Main chain cover-L 1 pc 39 Hex socket head bolt M8x38 2 pc

15 Inner chain cover-R 1 pc 40 Spring Φcp181x6.2

16 Inner chain cover-L 1 pc 41 Adjustment bar Φ6x60 1 pc

gnirpsdesserpmoC24cp1revocmirtediS71 Φ1.5x9 1 pc

cp2gulpknarC34cp1R-knarCSCP3R81

cp4T4.01x5.1x21MtuNegnalF44cp1L-knarCSCP3L81

19 Plastic cap for Crank 2 pc 45 Hex socket head bolt M8x15 3 pc

cp2T2x92x01rehsaW64cp1R-V403-DJladePR02

cp521x5Mwercsgnippat-fleS74cp1L-V403-DJladePL02

cp1redlohelttoB84cp262x61MbonkgnirpS12

cp201x5MwercS94cp102

x01Mbonk-L22

cp201x3MwercsspilihP05cp182x01MbonK32

eveelsleetS15cp101MtuNkcoL42 Φ12*17*9 1 pc

25 Washer 19.5x38x2T 1 pc 52 Self-tapping screw M4.5x15 2 pc

26R Magnet plastic cover-R 1 pc 53 Self-tapping screw M4.2x10 13 pc

YT'QYT'Q

Parts List

5

noitpircseD.oNnoitpircseD.oN

cp2T0.1x71x21rehsaW07cp153x6MtloB.xeH45

gniraebcitsalP17cp1erutxifleehweldI55 Φ12.8x21.4x6.7T 4 pc

56 Nylon nut M10x9T 2 pc 72 Plastic sleeve Φ7.9x12.7x23.5mm 2 pc

57 Steel sleeve Φcp2etalpdexiF37cp1T01x23x1.52

58 Steel bearing 6005-2RS 2 pc 74 Cushion knob M10x25 4 pc

59 C-ring ΦpaC57cp202 Φcp467

60 C-ring ΦleehwtropsnarT67cp152 Φ70 2 pc

cp101MbonklortnocnoisneT77cp1leehweldI16

cp251x5MtloB87cp1T3.0x43x72rehsawevaW26

cp201x5MtloB97cp2T2x02x01rehsawcitsalP36

64 Wire plug Φcp552x5.4Mwercsgnippat-fleS08cp1

71

65 Steel sleeve Φcp1paccitsalP18cp1T6x51x2.01

66 Axis Φ20x155mm 1 pc 82 Washer 12x24x1.5T 2 pc

67 Wave washer 21x27x0.3T 1 pc 83 Washer Φcp25

cp1revoccitsalP48cp1T5.0x52x5.02rehsaW86

69 Hex. Bolt M10x32 1 pc 85 Washer 10x16x1.5T 1 pc

YT'QYT'Q

6

Hardware and Tools List

15

13

NO.35 Cap nut

M10 4PCS

NO.37 Washer

10x19x1.5T 4PCS

17

14

NO.46 Washer

10x29x2T 2PCS

NO.25 Washer

19.5x38x2T 1PC

NO.24 Lock Nut

M10 1PC

NO.22 L-knob

M10 1PC

NO.23 Knob

M10x28 1PC

NO.36 Carriage bolt

M10x55 4PCS

Open end wrench

14,17mm 1PC

Open end wrench

13,15mm 1PC

Screwdriver 1PC

7

Overview Drawing

8

Assembly

9

10

11

12

How to use

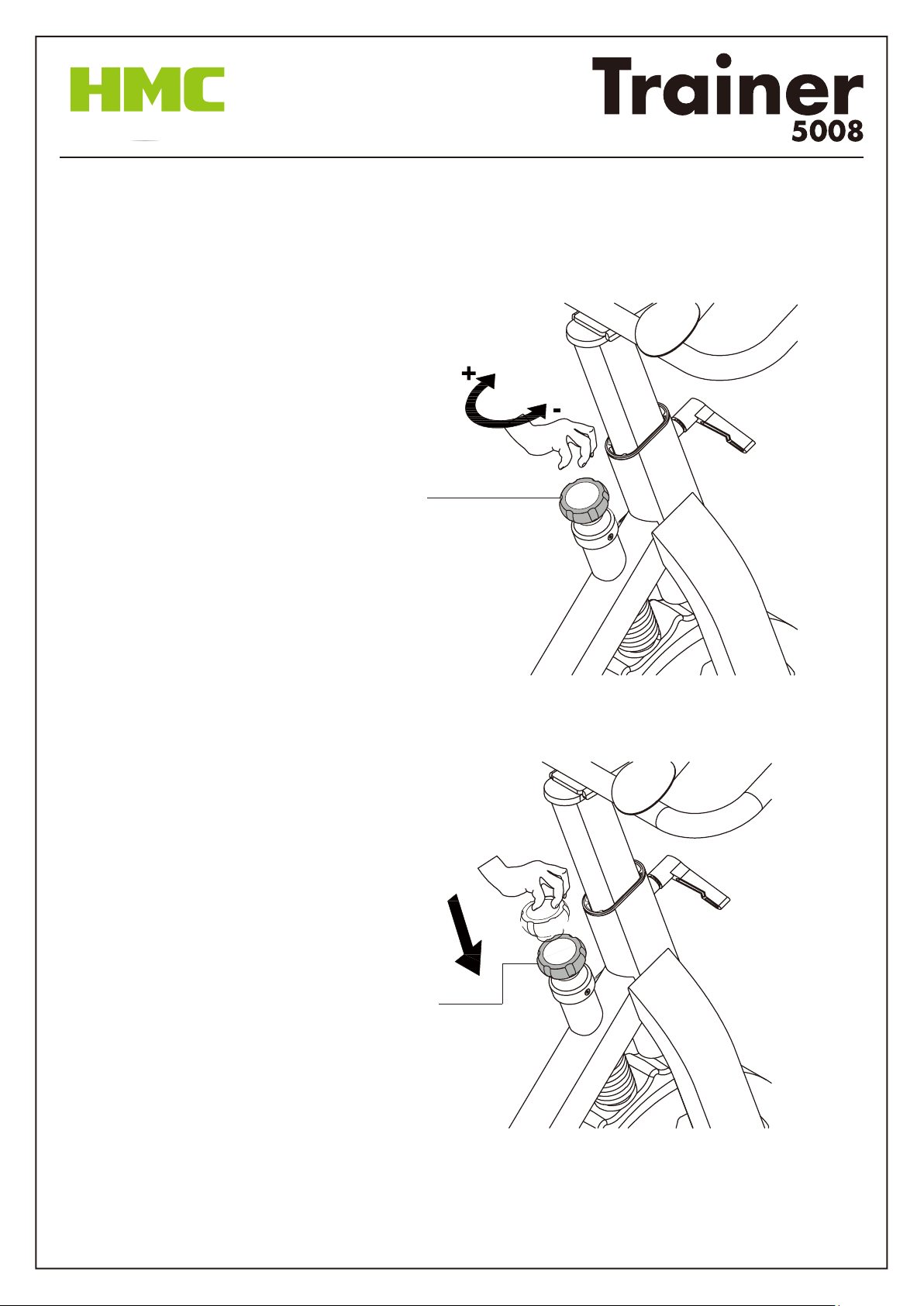

Tension Adjustment

Turn knob clockwise to increase tension

Turn knob counter-clockwise to decrease tension

Emergency Stop

Press down the knob to stop the flywheel

13

Quadriceps Stretch

With one hand against a wall for balance, reach behind you and

pull your right foot up. Bring your heel as close to your buocks

as possible. Hold for 15 counts and repeat with le foot up.

Inner Thigh Stretch

Sit with the soles of your feet together with your knees poinng

outward. Pull your feet as close to your groin as possible.

Gently push your knees towards the floor and hold for 15 counts

Toe Touching

Slowly bend forward from your waist, leng you back and

shoulders relax as you stretch toward your toes. Reach down

as far as you can and hold for 15 counts.

Hamstring Stretch

Sit with your right leg extended. Rest the sole of your le

foot against your right inner thigh. Stretch toward your toe

as far as possible. Relax and hold for 15 counts. Repeat with

le leg extended

Warm Up

14

The bike trainer wobbles or shakes when in use

Turn the adjustable leveler on the front stabilizer or rear stabilizer as needed to level the

bike trainer.

TROUBLESHOOTING

Squeaking noise when in use

The bolts may be loose on the bike trainer. Inspect all bolts and ghten as needed.

MAINTENANCE

Cleaning

The bike trainer can be cleaned with a so cloth and mild detergent. Do not use abrasives

or solvents on plasc parts. Please wipe your perspiraon off the bike trainer aer each

use. Please inspect all assembly bolts and pedals on the machine for proper ghtness

every week.

Storage

Store the bike trainer in a clean and dry environment away from children.

Thread sealant instrucon

If any parts need to be applied thread sealant, the parts must be cleaned before applying.

It needs at least 12 hours to a day to wait the sealant dry, do not use the bike unl the

thread sealant is fully dry.

www.hmcspin.com

Table of contents

Popular Exercise Bike manuals by other brands

Body Sculpture

Body Sculpture BC-6800G-HB Assembly and operating guide

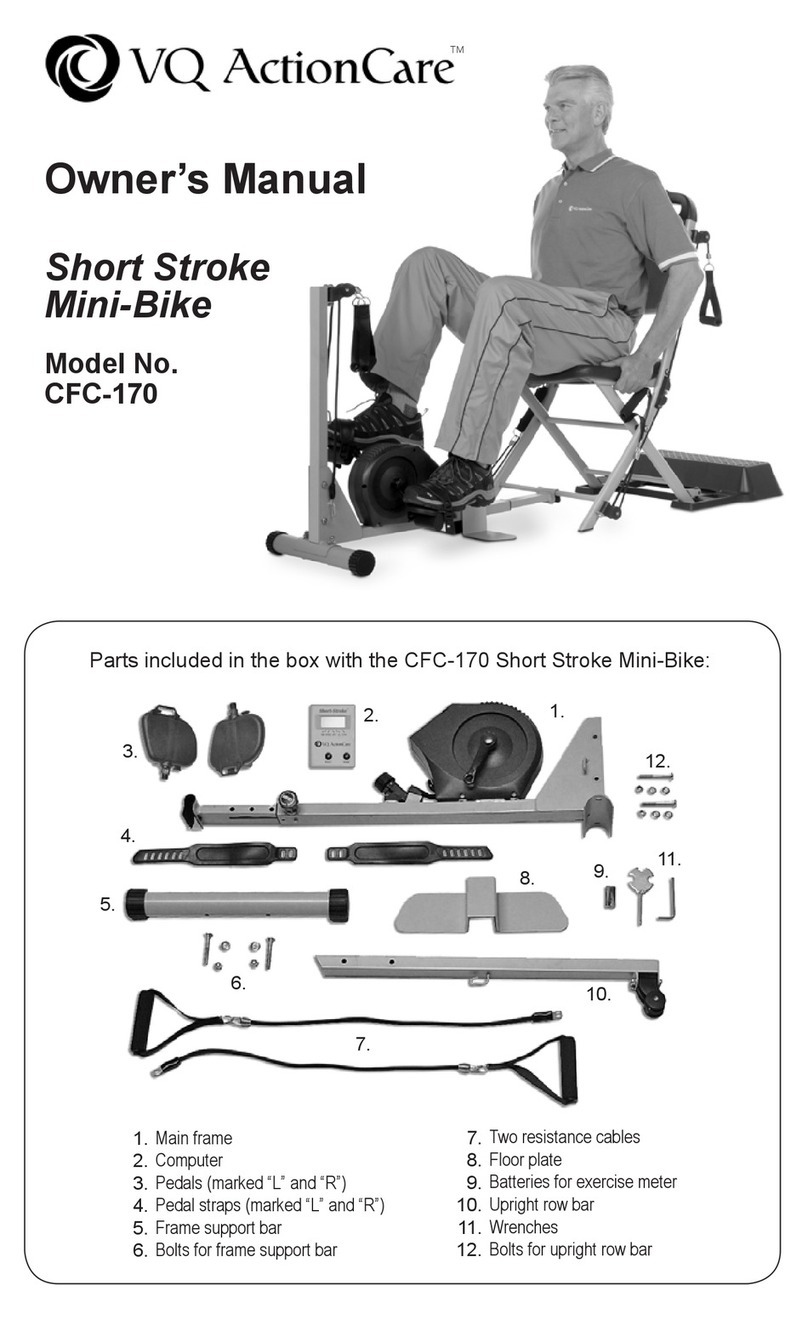

VQ ActionCare

VQ ActionCare CFC-170 owner's manual

Stages cycling

Stages cycling StagesBike Assembly and Start Up Guide

SportsArt Fitness

SportsArt Fitness C530 owner's manual

AB-Bike

AB-Bike E0001-00 User Manual and Workout

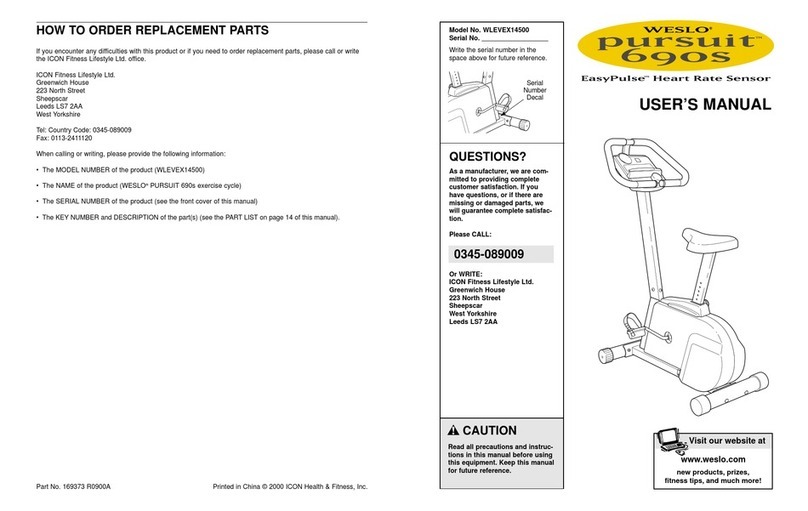

Weslo

Weslo Pursuit 690s user manual

Vision Fitness

Vision Fitness R2000 Assembly instruction

Reebok

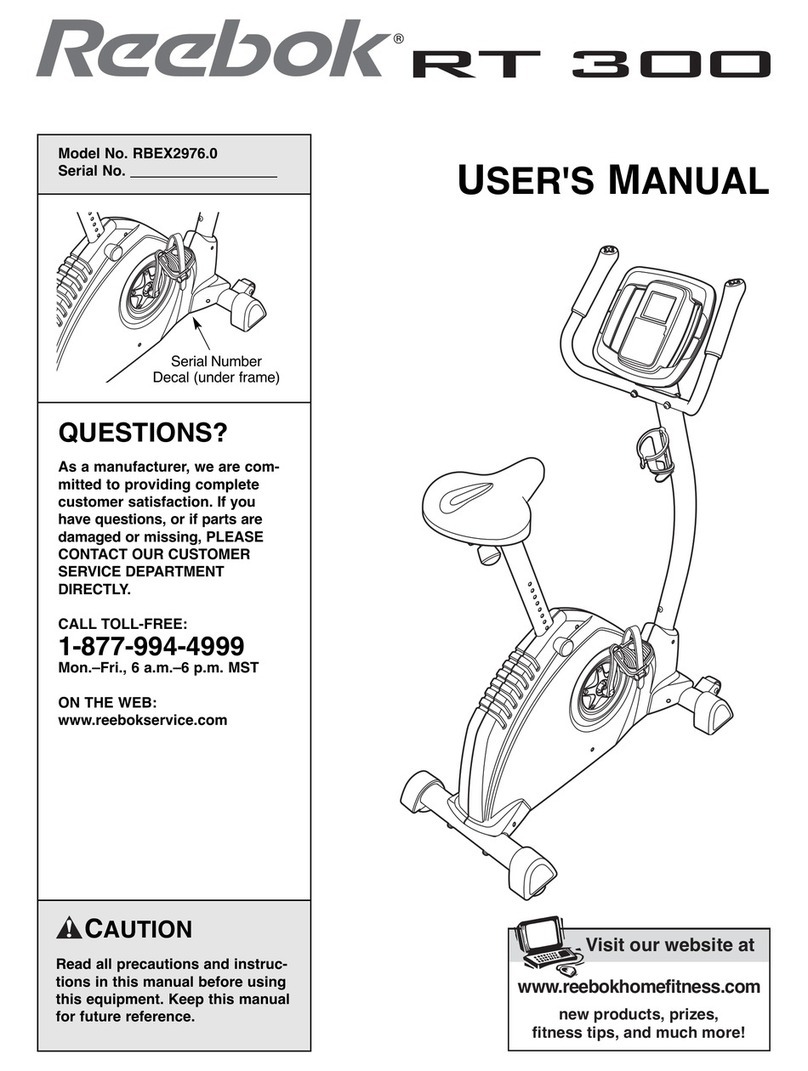

Reebok RT 300 RBEX2976.0 user manual

Tunturi

Tunturi S30 user manual

MINOURA

MINOURA B60-D instruction manual

HIT FITNESS

HIT FITNESS G8 PRO user manual

Christopeit Sport

Christopeit Sport KINOMAP RACER BIKE 4.0 Assembly and operating instructions