HV350 Mini Frequency Inverter User Manual

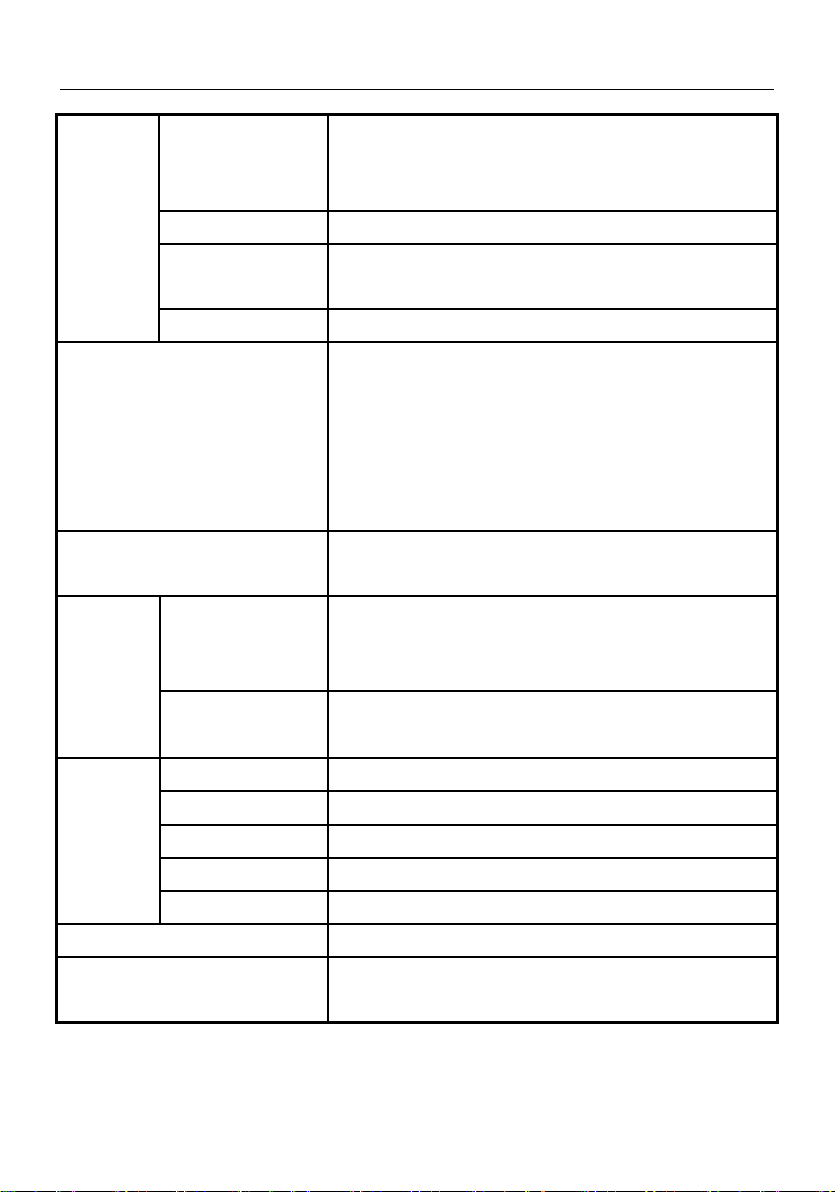

Contents

Chapter 1 Introduction to HV350 Series Inverter ...............................................................................3

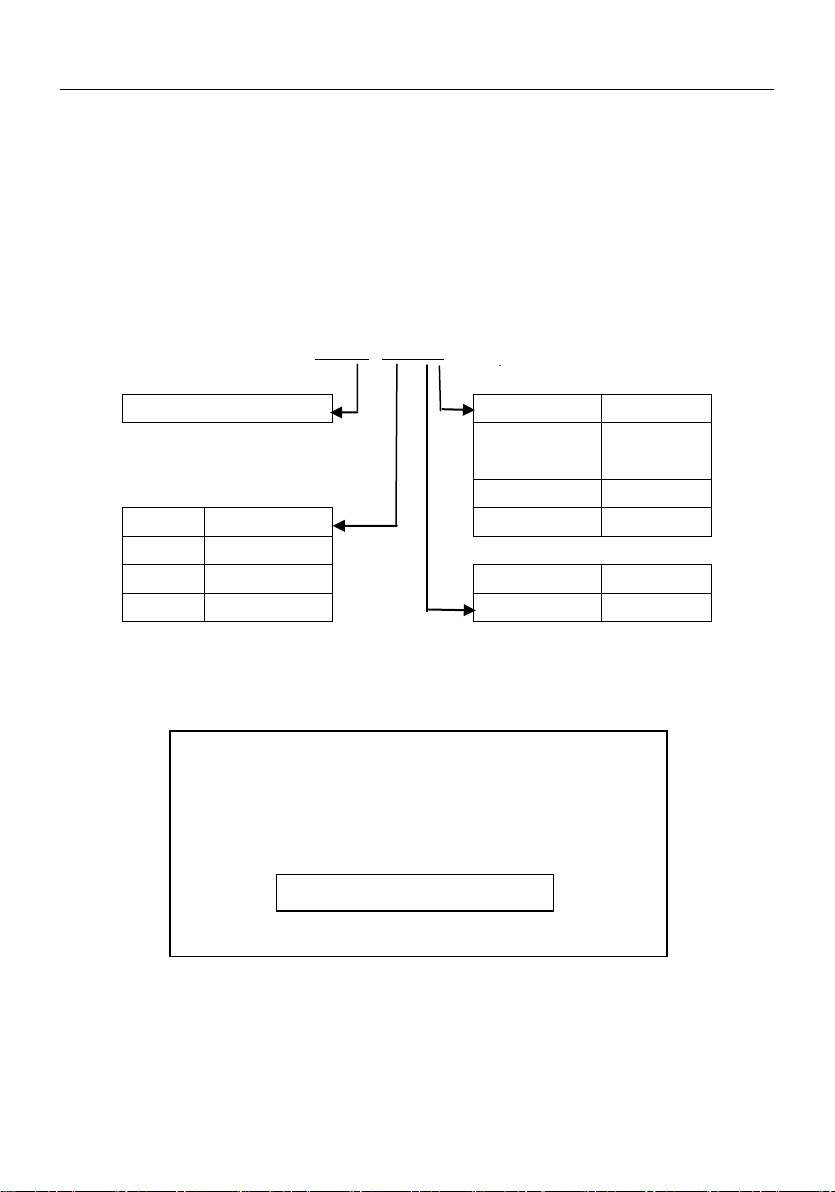

1.1 Product Model Description..................................................................................................................3

1.2 Safe Precaution..................................................................................................................................4

1.3 Product Series....................................................................................................................................7

1.4 Product Specifications........................................................................................................................8

1.5 Product Component Name...............................................................................................................10

1.6 Product Outline, Mounting Dimension, and Weight ...........................................................................10

1.7 Operation Panel Outline and Mounting Dimension............................................................................11

1.8 Braking Resistor Lectotype...............................................................................................................11

Chapter 2 Inverter Installation...........................................................................................................12

2.1 Environment for Product Installation.................................................................................................12

2.2 Mounting Direction and Space..........................................................................................................12

2.3 Removal and Mounting of Operation Panel and Cover......................................................................13

Chapter 3 Wiring of Inverter..............................................................................................................16

3.1 Connection of the Product and Peripheral Devices ...........................................................................16

3.2 Description of Peripheral Devices for Main Circuit.............................................................................17

3.3 Lectotype of mMain Circuit Peripheral Devices.................................................................................18

3.4 Product Terminal Configuration.........................................................................................................18

3.5 Functions of Main Circuit Terminal....................................................................................................18

3.6 Attention for Main Circuit Wiring........................................................................................................20

3.7 Terminal Wiring ................................................................................................................................20

3.8 Functions of Control Circuit Terminals...............................................................................................21

3.9 Lectotype of Control Circuit Peripheral Devices ................................................................................23

Chapter 4 Using Instructions of Operation Panel ............................................................................24

4.1 Introduction to Operation Panel........................................................................................................24

4.2 Descriptions of Indicators .................................................................................................................25

4.3 Description of Keys on Operation Panel............................................................................................25

4.4 Keypad Operating Status..................................................................................................................25

4.5 Panel Operation Method...................................................................................................................25

4.6 Parameter Display............................................................................................................................28

4.7 Motor auto-tuning procedure ............................................................................................................29

4.8 Running for the First Time................................................................................................................29

Chapter 5 List of Parameters ............................................................................................................30

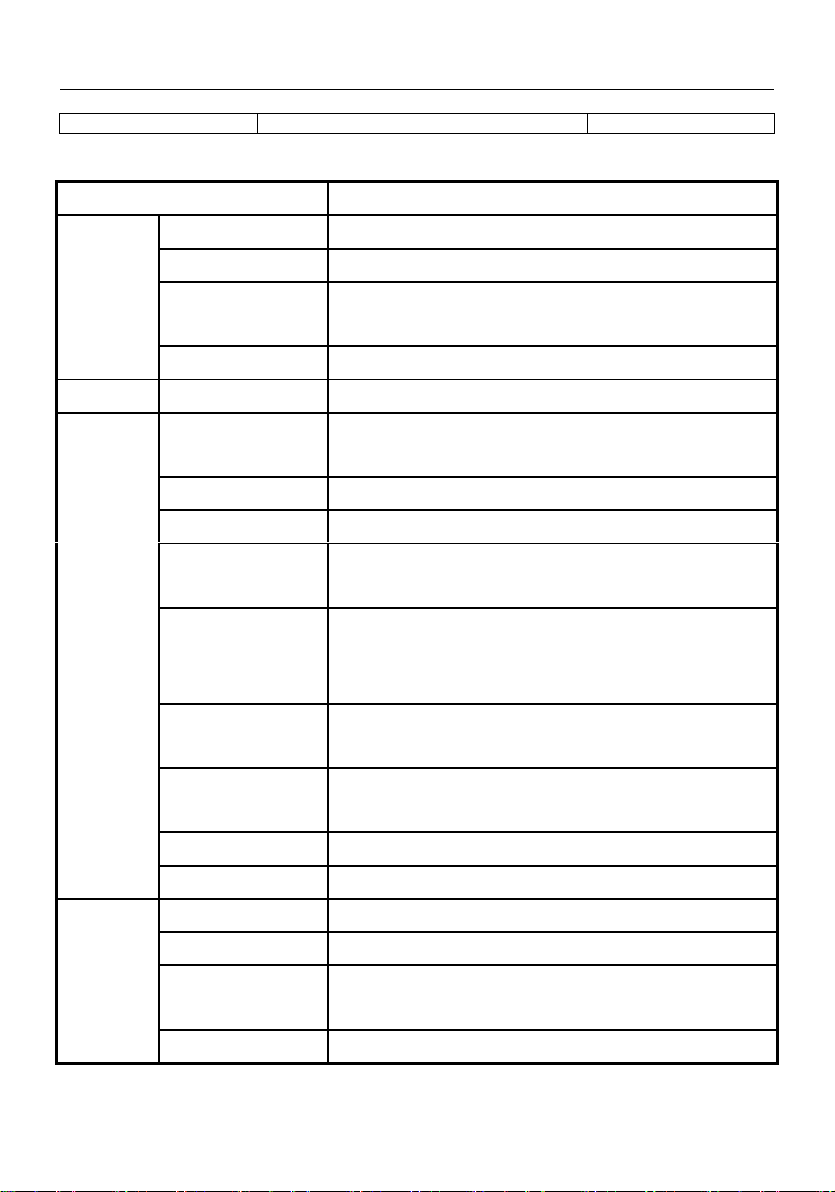

5.1 Function Parameter Table.................................................................................................................30

Chapter6 Detail Function Introduction................................................................................................49

P0 Basic function parameters.................................................................................................................49

P1 Auxiliary function parameters 1 .........................................................................................................54

P2 Auxiliary function parameters 2 .........................................................................................................58