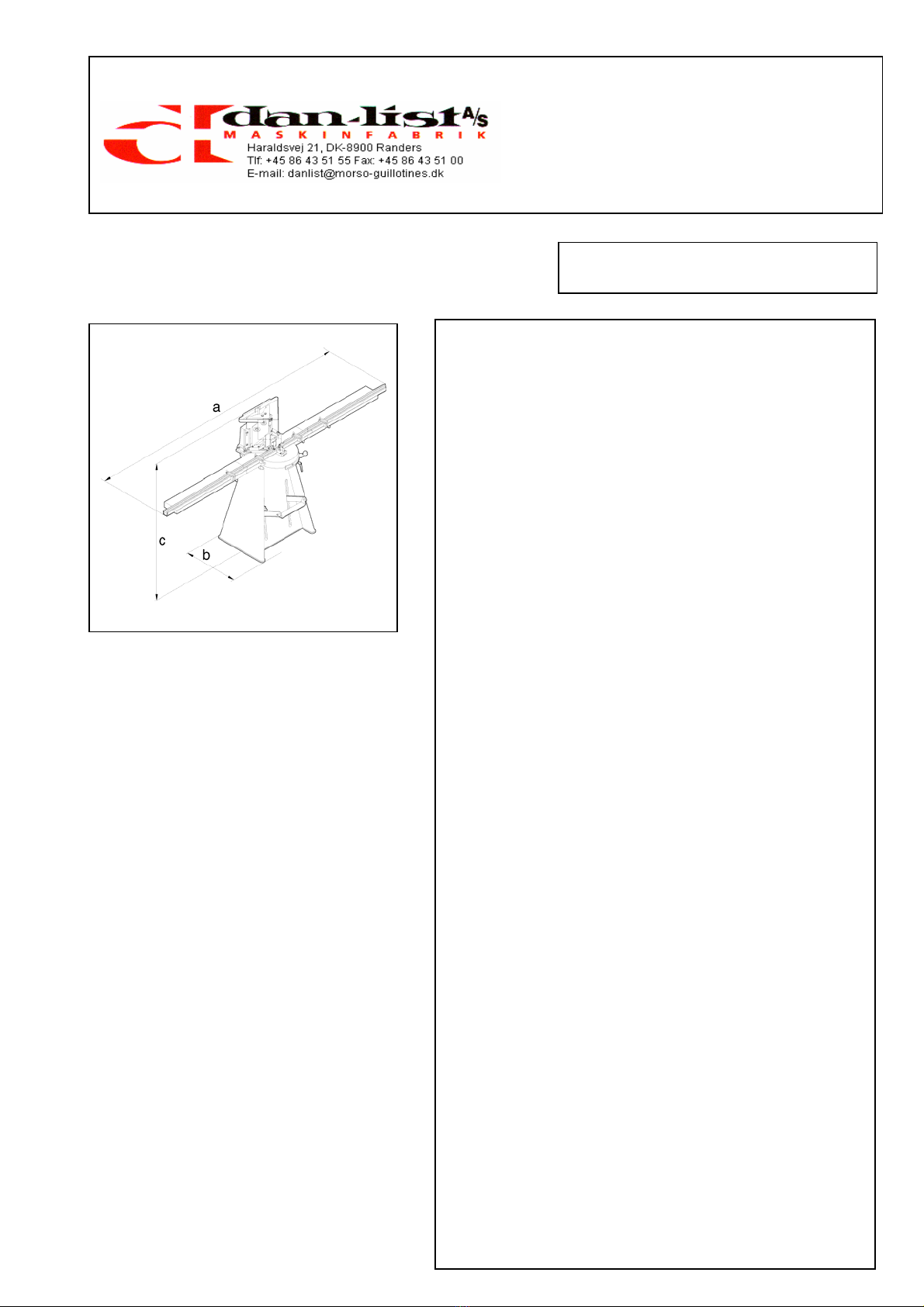

Instructions Manual

MORSØ

Notch Cutting Machine

Model NF

-

In General

The machine is delivered ready for start and

complete with standard equipment.

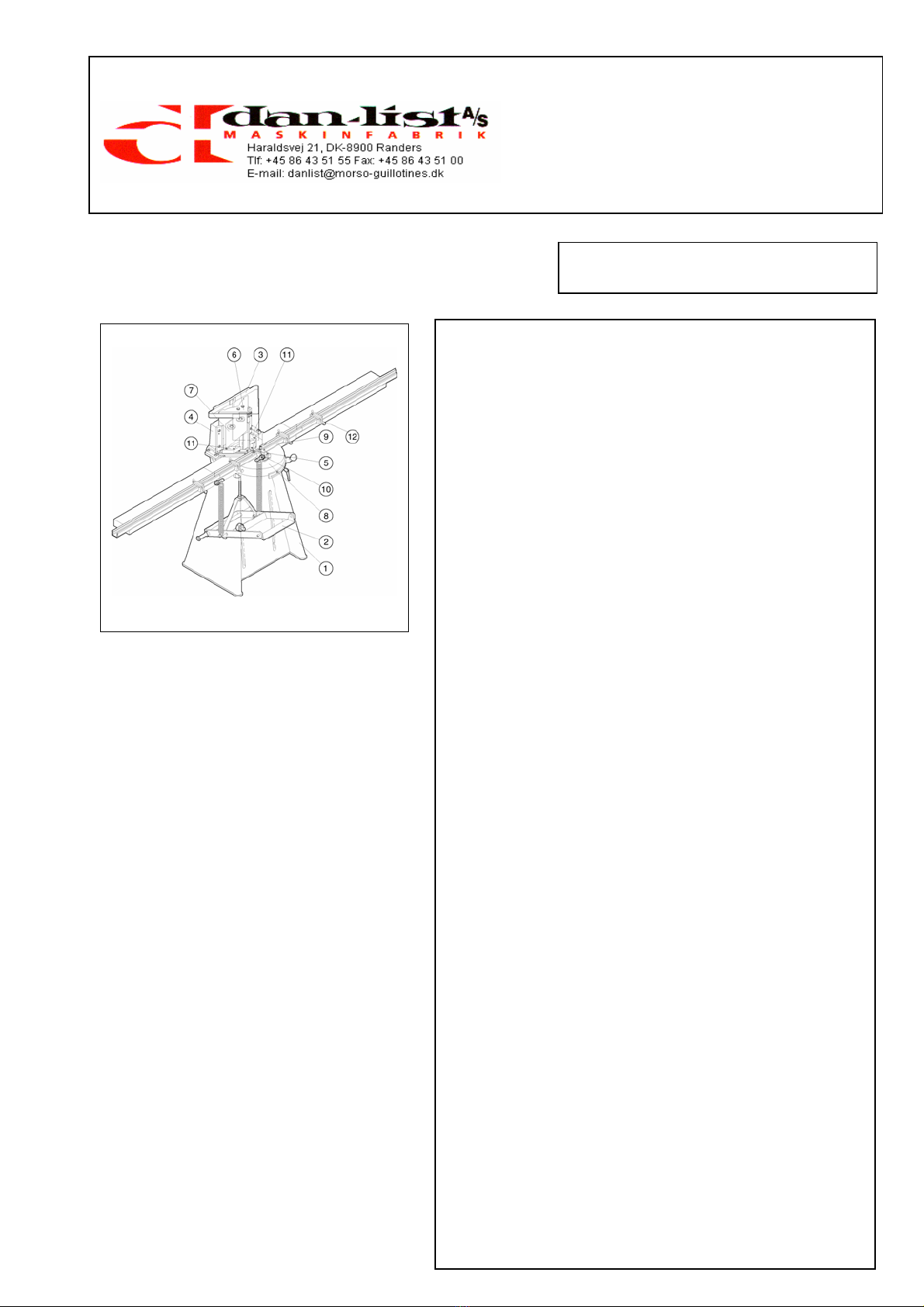

Only the table extensions (1) and fences (2) are

dismounted during transport.

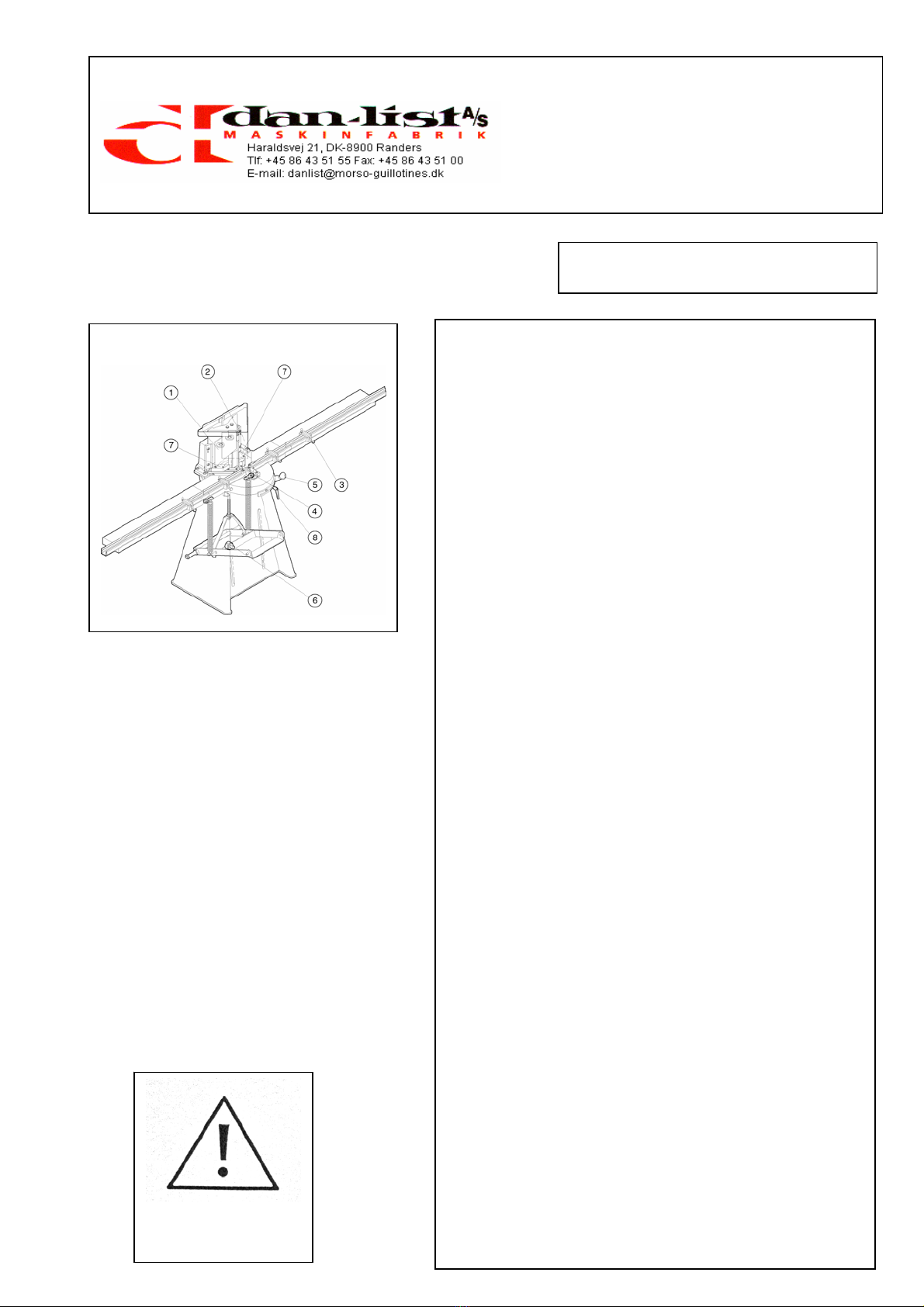

NOTE before starting up first time:

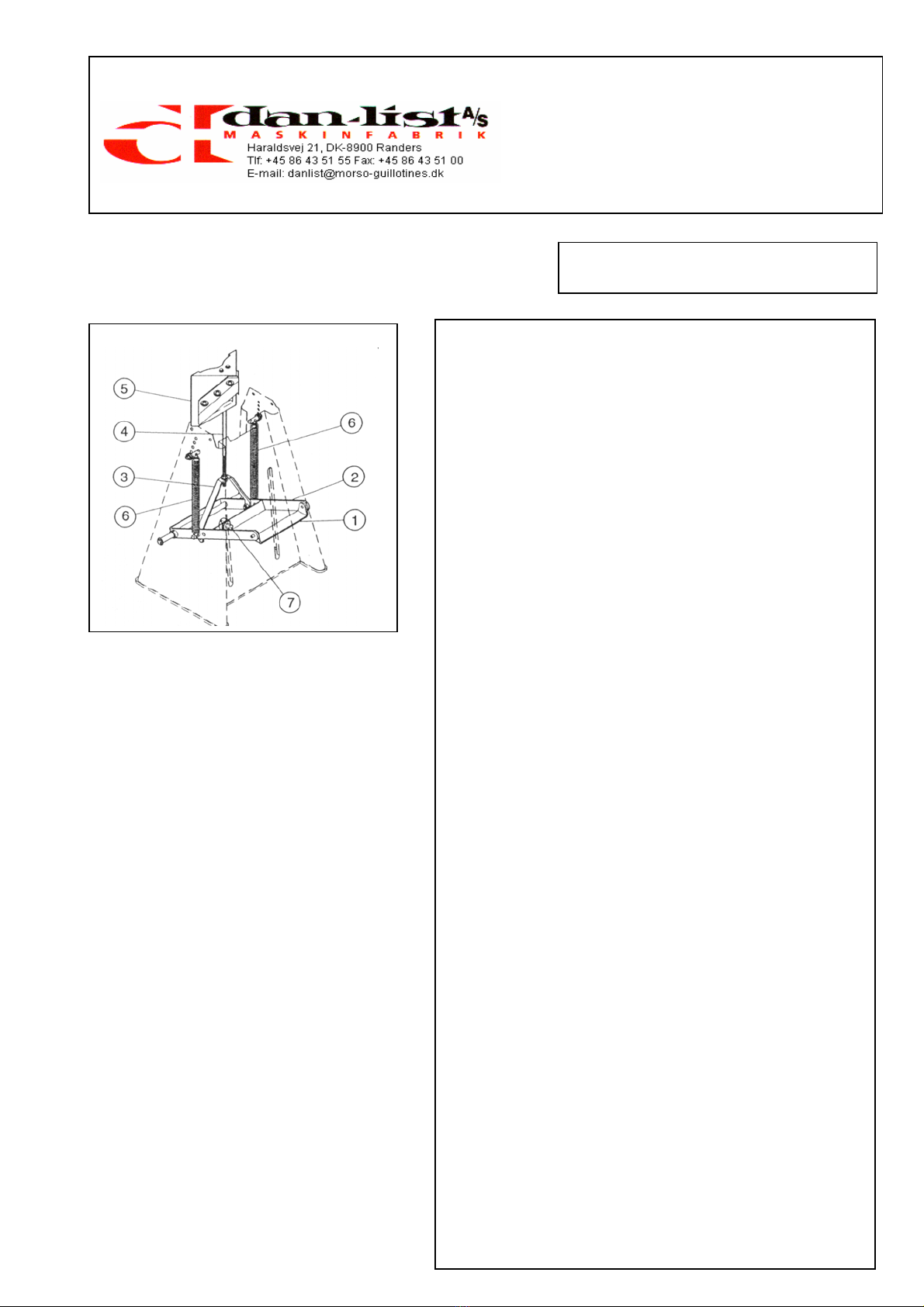

1. The handle on the tooth arc is loosened (it

functions as the rear stop when moving the

knife block backwards).

2. The knife block is moved halfway backwards,

and the waste chute is fitted.

Placing according to the spaciousness to wall

stated in D-1. The machine can be fastened to the

floor with screws in the two holes in the bottom of

the machine frame.

Check before each start that all protection

devices are fitted correctly.

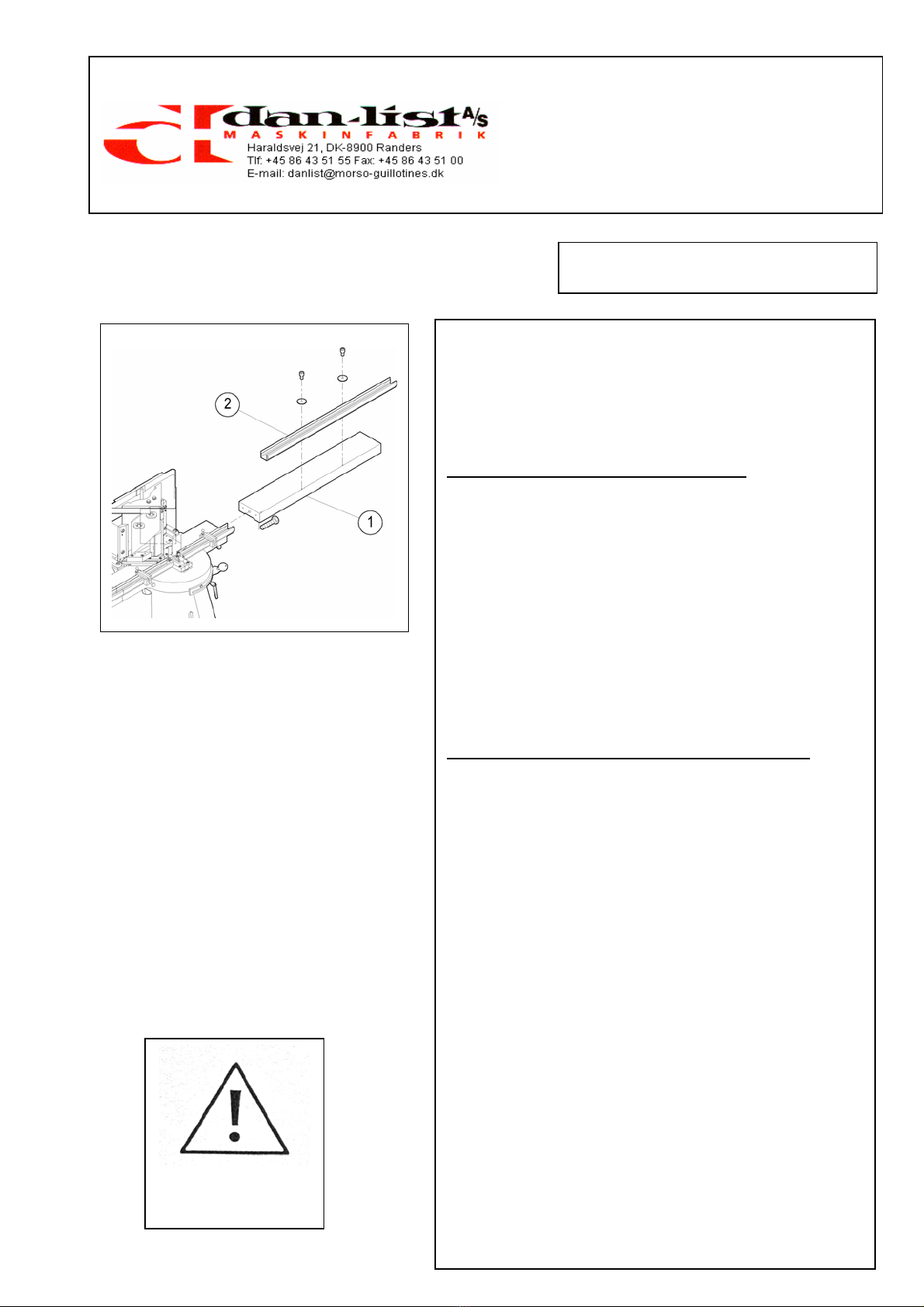

Fitting of the Table Extension and fences

(on the drawing the right side is shown, the same

procedure on the left side).

Before fitting the table extension (1) the ends of

the table extension and the table must be cleaned

very thoroughly. Special attention must be paid to

the pin and screw holes, as the smallest amount

of dirt will prevent the correct alignment.

After the cleaning, the table extension is pressed

against the table so that the pins placed in the

table extension are inserted in the pin holes in the

table. The included screw is now inserted in the

screw hole and fastened with a standard screw

driver.

The fence (2) is fitted on the table extension (pins

are fitted in the table extension). It is fastened with

cylinder screw.

(Extra extension table and supporting leg can be

delivered as accessories).

BEWARE OF THE

EXTREME SHARP

KNIVES