2XL-AR452 Rev. C

TABLE OF CONTENTS

Introduction...............................................................................2

Warranty ....................................................................................2

Notes, Cautions, and Warnings...................................................2

Installation Preparations ............................................................3

Installation .................................................................................3

Plumbing Diagram .....................................................................5

Parts List.....................................................................................5

Operating Instructions...............................................................6

Contact Information ..................................................................8

INTRODUCTION

This manual provides you information necessary for the

installation, adjustment, inspection, and safe operation of the

Holland air release feature for Trailer Sliding Suspensions.

No more pulling. New Air release effectively retracts and engages

slider pins with the pull/push of a knob. For added simplicity,

the Air Release operates with a proven design air brake chamber

just likecurrent braking systems.

No training is required and faster slide relocation is enabled by

the simple switch operation.

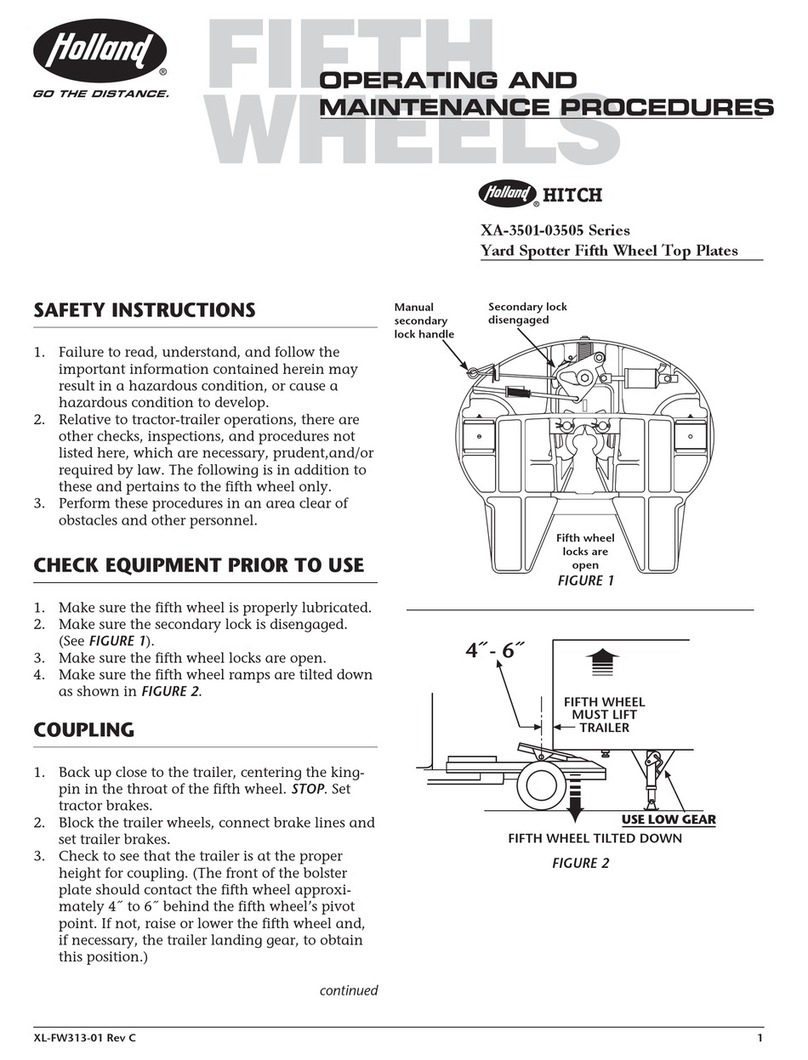

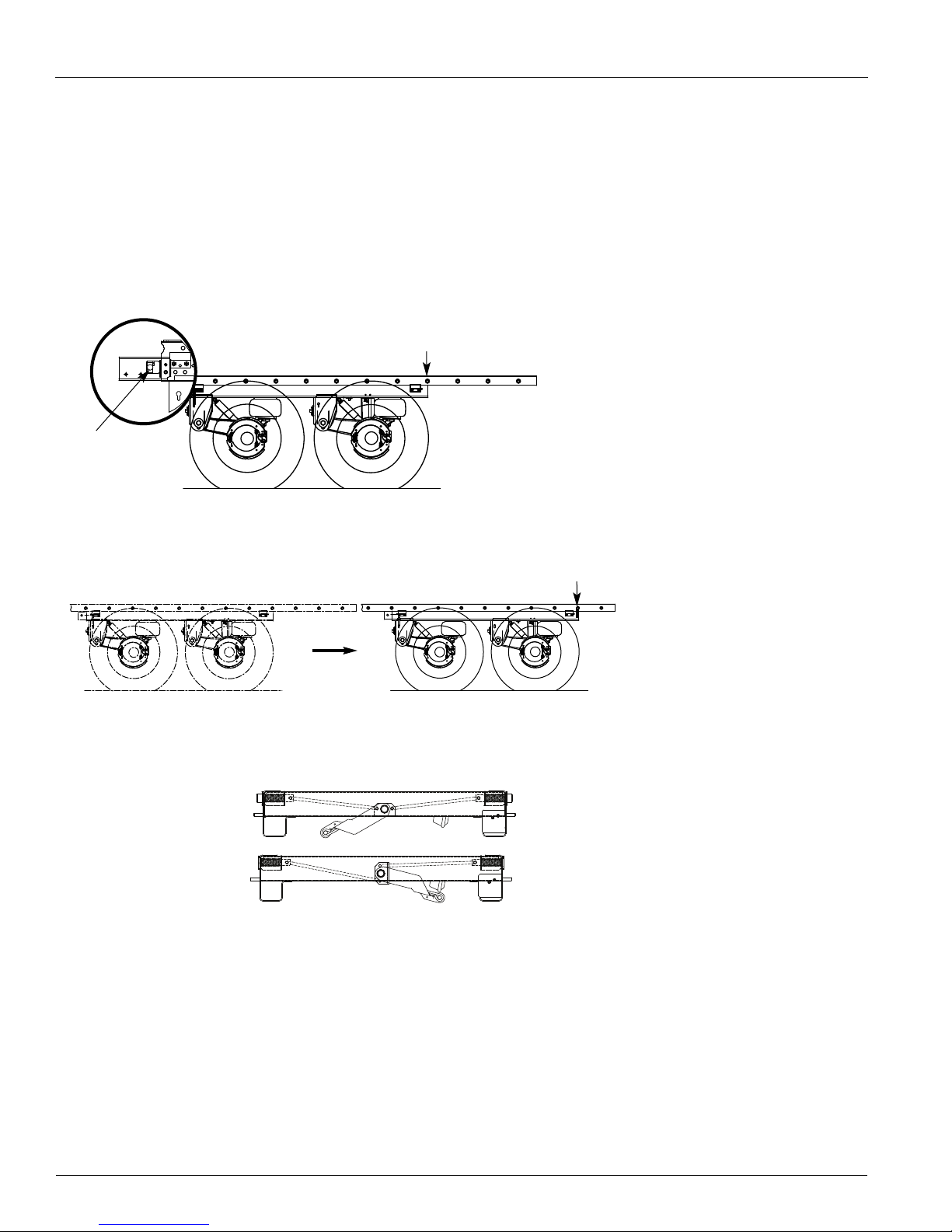

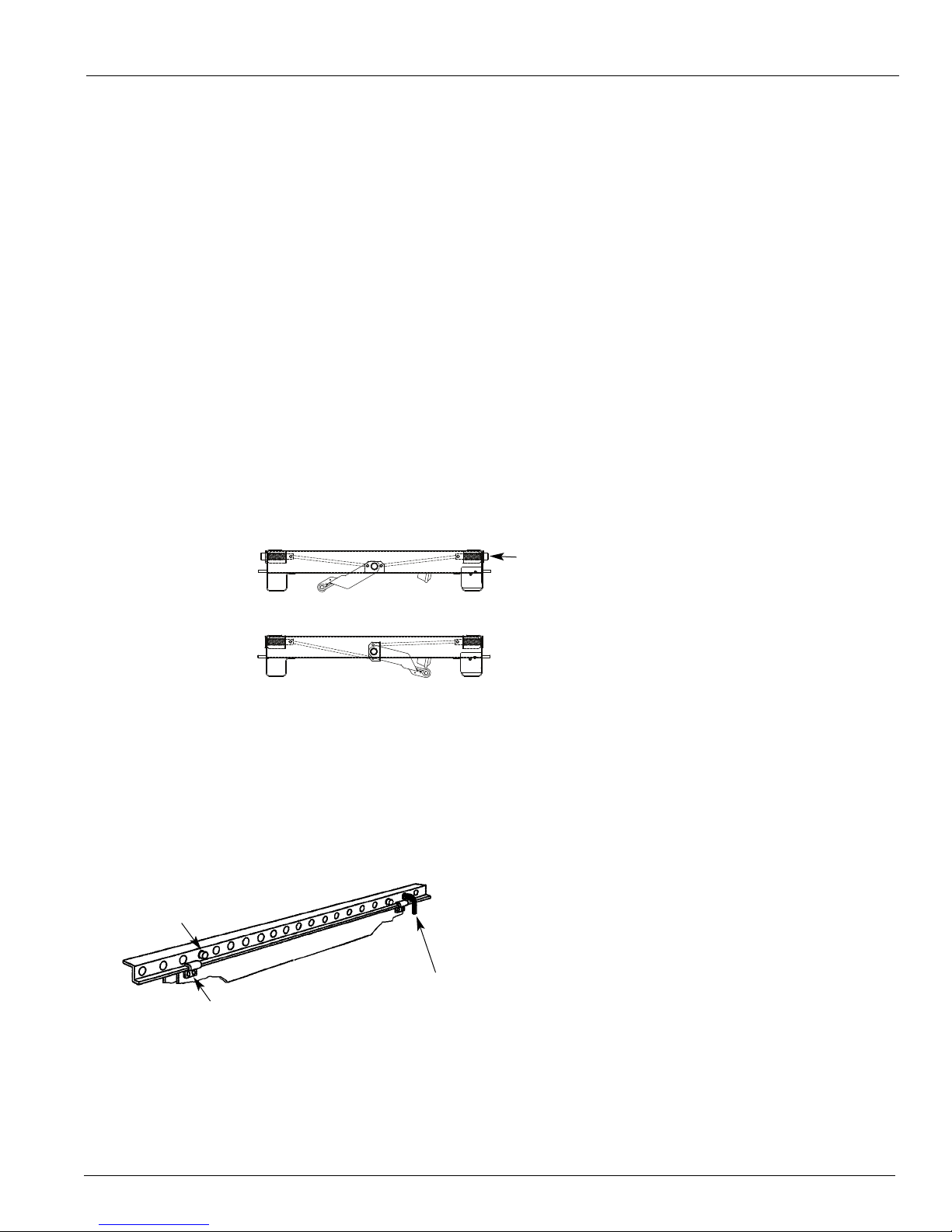

To adjust the slide, the driver must park on level ground and set

all the brakes.The driver reloactes the stop bar to the desired

location and pulls out the Air Release knob located on the front

of the slider. The air brake chamber then releases the pins and

locks in the out position to allowmovement.When pins have

released the driver slowly repositions the tractor until slide

contacts the manual stop bar. Set tractor brakes after positioning

is complete. Push in the knob and pins automatically engage and

lock into place.

The driver must check to ensure lock pins extend through upper

rail.As an added measureof safety, the stop bar must be relocat-

ed 1 hole behind slider before operating the vehicle.

For added driver safety, the Air Release only works when the

parking brake is set and is connected to the air supply with a

valve to prevent draining.

Air Release is available on all models of Holland slides - new and

retrofit. Optional manual back up also is available.

WARRANTY

Refer to the complete warranty for the country in which the

product will be used.A copy of the written warranty is included

with the product as well as in the suspension catalogs and on

the Holland Group Web Site (www.safholland.us).

It may also be ordered directly by calling 1-888-396-6501.

NOTES, CAUTIONS,

AND WARNINGS

You must read and understand all of the safety procedures

presented in this manual before starting any work on

the suspension.

Proper tools must be used to perform the maintenance and

repair procedures described in this manual. Many of these

procedures require special tools.

Failure to use the proper equipment could result in

personal injury and/or damage to the suspension.

Safety glasses must be worn at all times when

performing the procedures covered in this manual.

Throughout this manual, you will notice the terms “NOTE,”

“IMPORTANT,”“CAUTION” and “WARNING” followed by impor-

tant product information. So that you may better

understand the manual, those terms are as follows:

NOTE: Includes additional information to enable accurate

and easy performance of procedures.

IMPORTANT: Includes additional information that

if not followed could lead to hindered

product performance.

Used without the safety alert symbol,

indicates a potentially hazardous situation

which, if not avoided, may result in

property damage.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor

or moderate injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.