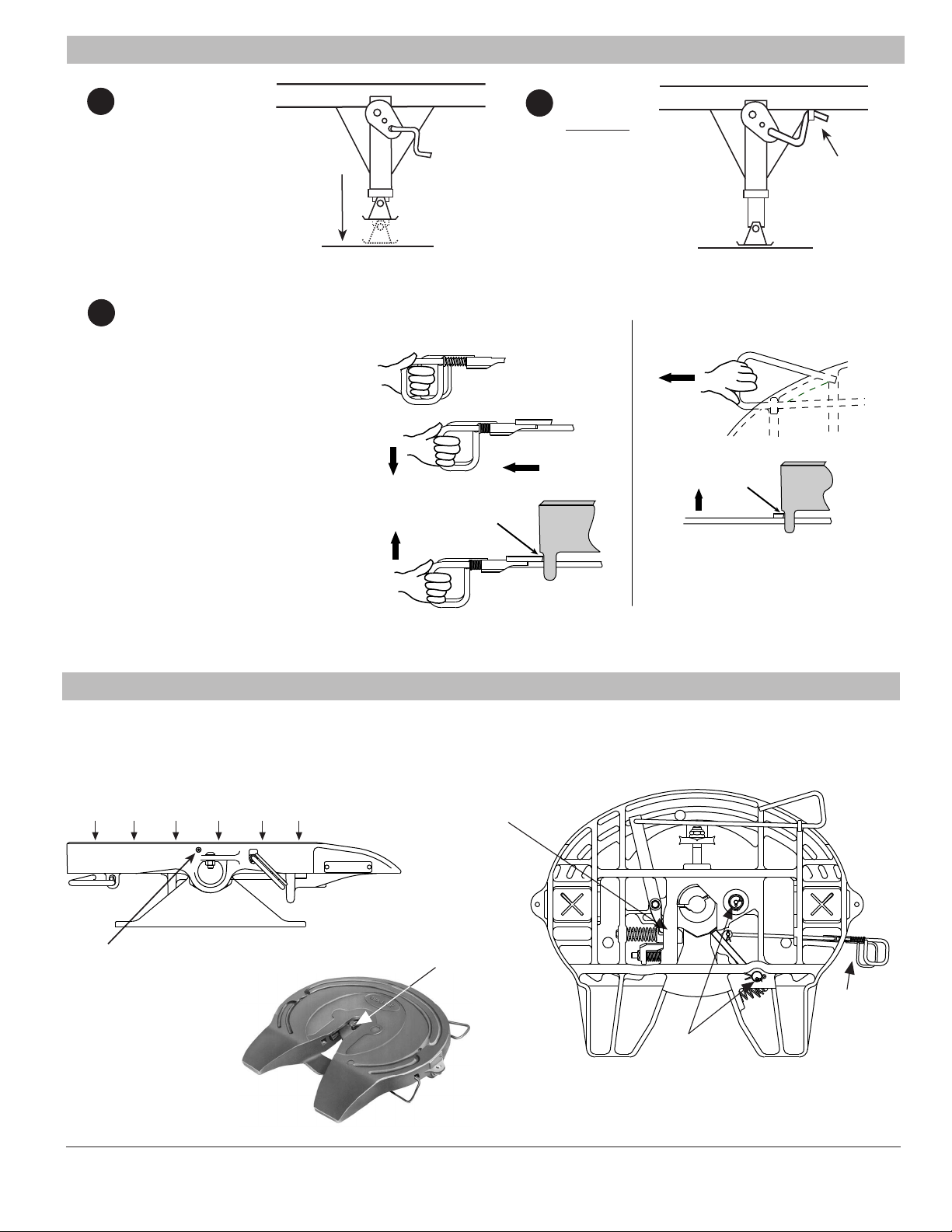

3 MAINTENANCE PROCEDURES

3.2 Required Inspections and Adjustments

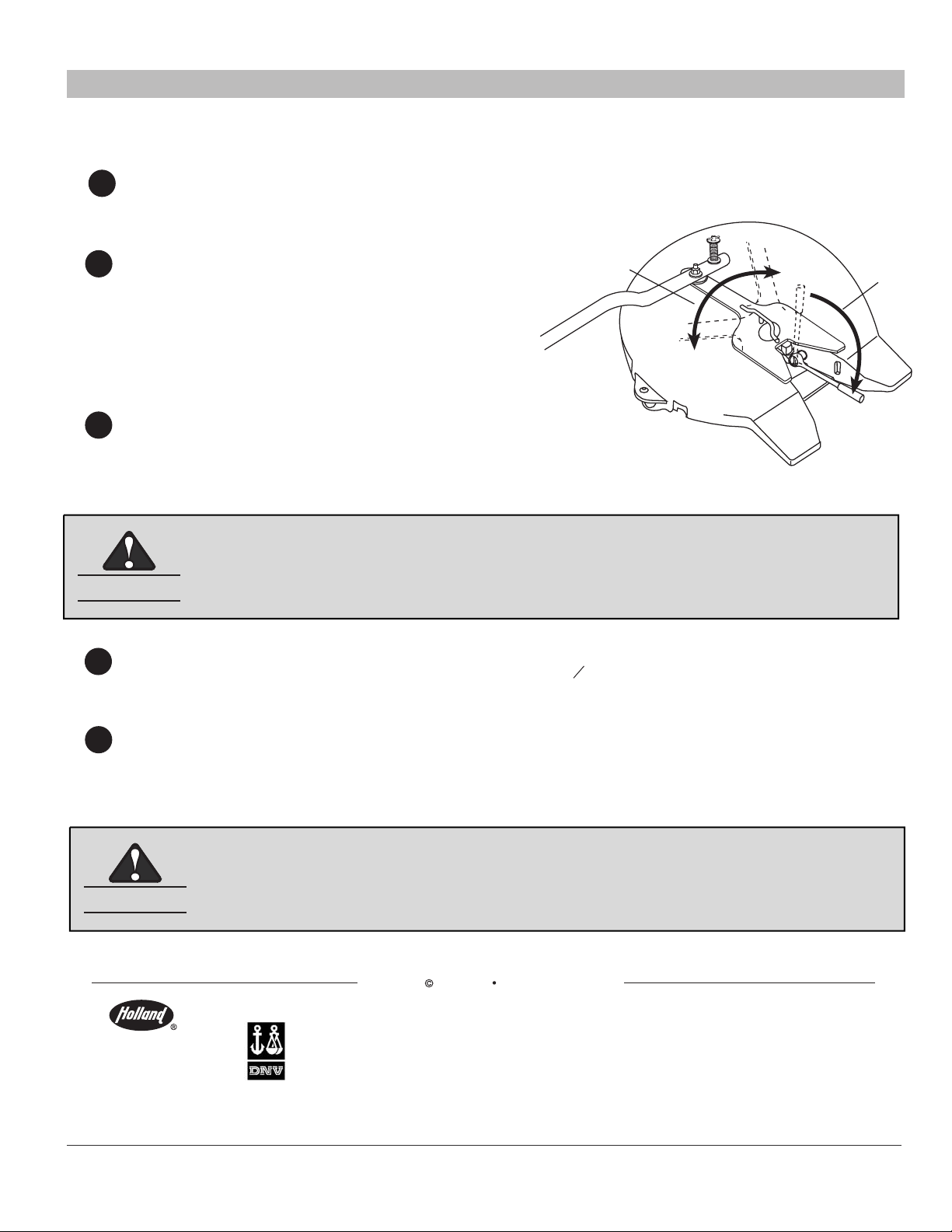

3.2.3 Lock Adjustment Procedure

2Using a socket wrench with a 1/2" Allen hex

bit socket, tighten the lock by turning the lock

adjustment bolt clockwise 1/4 turn at a time.

Remove the socket wrench from the bolt

and rotate the tool as shown to check for

resistance between the tool and lock.

TIGHTEN

ROTATE

TOOL

3Continue to alternate tightening (clockwise)

the adjustment bolt 1/4 turn at a time, until the fifth

wheel lock is tight against the kingpin in the lock tester.

4Loosen the adjustment bolt (counter-clockwise) 1 turns.

The lock is now properly adjusted.

5Verify the proper adjustment by locking and unlocking the fifth wheel several times

with the lock tester. On each attempt, make sure the locks properly engage.

1Using Holland TF-TLN-5001 Lock Adjustment Tool, lock the fifth wheel and verify

that it is closed as shown in Step 10 on Page 5.

12

XL-FW1083-01 8

WARNING

At this point the fifth wheel is OVER-ADJUSTED and NOT usable.

The remaining adjustment procedures must be completed.

WARNING

Improper adjustment can cause improper locking of the fifth wheel.

If the fifth wheel does not operate properly, DO NOT USE IT!

Repeat the adjustment procedures or contact Holland.

Copyright June 2004 The Holland Group Inc.

Holland Europe GmbH

Altenkamp 9

D-33758

Schloss Holte-Stukenbrock

Germany

Phone: +49 (0) 5207-89560

Fax: +49 (0) 5207-895656

Holland Eurohitch Ltd.

Hoo Farm Industrial Estate

Worcester Road

Kidderminster

Worcestershire

DY11 7RA

Phone: +44 (0) 1562-732010

Fax: +44 (0) 1562-732020

Holland Transtrade

Far East SDN BHD

Shah Alam, Malaysia

Phone: 60 (0)3 734-2888

Fax: 60 (0)3 736-5588

The Holland Group, Inc.

Holland, MI 49423

United States

Phone: (616) 396-6501

Fax: (616) 396-1511

Holland Transtrade

(Thailand) Company, Ltd.

Bangkok, Thailand

Phone: 66 (0)2-513-8758

Fax: 66 (0)2-513-8757

Nippon Holland, Ltd.

Tokyo, Japan

Phone: 81-(0)3-3461-9130

Fax: 81-(0)3-3463-1407

Holland Hitch (Aust.) Pty. Ltd.

Melton, Victoria, Australia

Phone: 61-(0)3-9743-6799

Fax: 61-(0)3-9747-9617

EN ISO

9001:2000

Certified

Company