7

XL-FW20130RM-en-US Rev C · 2022-01-03 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

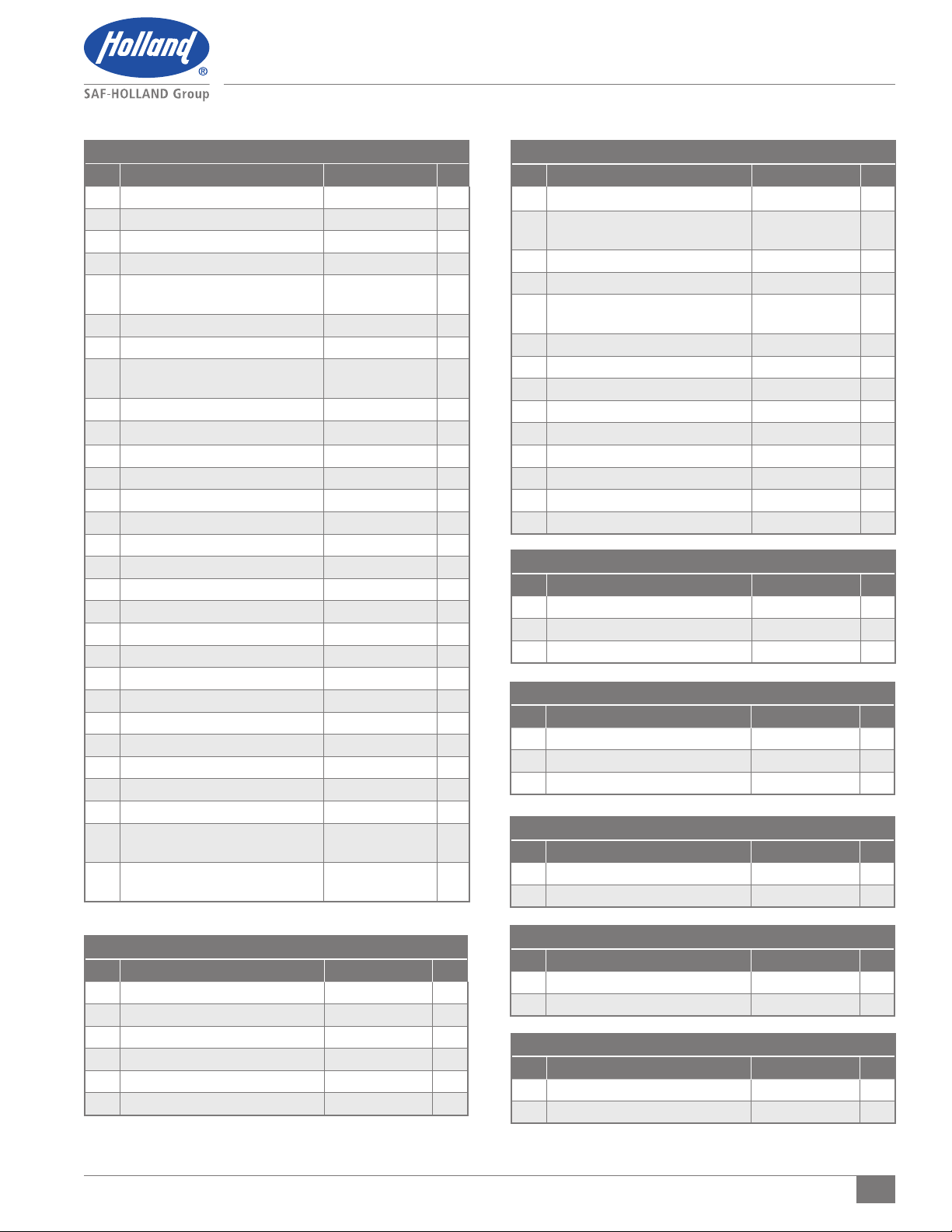

Parts List

RK-351-TT AND RK-351-UBT PARTS LIST

ITEM DESCRIPTION PART NUMBER QTY

1Yoke XA-12044-P 1

2 Yoke Shaft XA-12038-ST 1

3 Yoke Spring XB-1505-P 1

4 Spring Block XD-12028-P 1

5Hex Head Cap Screw,

M12 x 1.75 x 40 mm XB-HCS-M12-40-Z 5

6 Roller, 5/8" I.D. XA-1507-1-P 1

7 Washer, 5/8" I.D. x 1-3⁄4" O.D. XB-460 1

8Hex Head Cap Screw, M16 x 2 x

50 mm (Yoke/Cam Connection) XB-12049 1

9 Roll Pin, Ø1/2" x 2-3/4" XB-21-S-500-2750P 1

10 Torsion Spring XB-2149-P 1

11 Secondary Lock XA-3542-T-P 1

12 Lock Nut, M12 x 1.75 XB-HLN-M12-Z 3

13 Washer, 14 mm I.D. x 45 mm O.D. XB-76004 2

14 Cam Plate Assembly XA-12036-A 1

15 Roller, 1/2" I.D. XA-1029-P 1

16 Cam Spring, Inner XB-10087-P 1

17 Cam Spring, Outer XB-10088-P 1

18 Clevis Pin XA-12039-P 1

19 Washer, 5/8" I.D. x 1-1/4" O.D. XB-06180 1

20 Bushing XA-10810-P 2

21 Air Cylinder XA-12057 1

22 Lock Pin XA-12046-P 2

23 Lock Set XA-08332-1-P 1

24 Lock Pin Washer, 1-1/8" I.D. x 2" O.D. XB-10249 2

25 Lock Nut, M27 x 3 XB-12027 2

26 Lock Spring XB-07628-P 1

27 Never-Seez®(Not Shown) XB-02967 1

28a Pocket Insert (included with

RK-351-TT kit) XD-12026-P 2

28b Pocket Insert (included with

RK-351-UBT kit) XD-08908-P0 2

RK-12196 PARTS LIST

ITEM DESCRIPTION PART NUMBER QTY

2 Yoke Shaft XA-12038-ST 1

5Hex Head Cap Screw,

M12 x 1.75 x 40 mm XB-HCS-M12-40-Z 3

6 Roller, 5/8" I.D. XA-1507-1-P 1

7 Washer, 5/8" I.D. x 1-3⁄4" O.D. XB-460 1

8Hex Head Cap Screw, M16 x 2 x

50 mm (Yoke/Cam Connection) XB-12049 1

12 Lock Nut, M12 x 1.75 XB-HLN-M12-Z 3

13 Washer, 14 mm I.D. x 45 mm O.D. XB-76004 2

14 Cam Plate Assembly XA-12036-A 1

15 Roller, 1/2" I.D. XA-1029-P 1

16 Cam Spring, Inner XB-10087-P 1

17 Cam Spring, Outer XB-10088-P 1

18 Clevis Pin XA-12039-P 1

19 Washer, 5/8" I.D. x 1-1/4" O.D. XB-06180 1

20 Bushing XA-10810-P 1

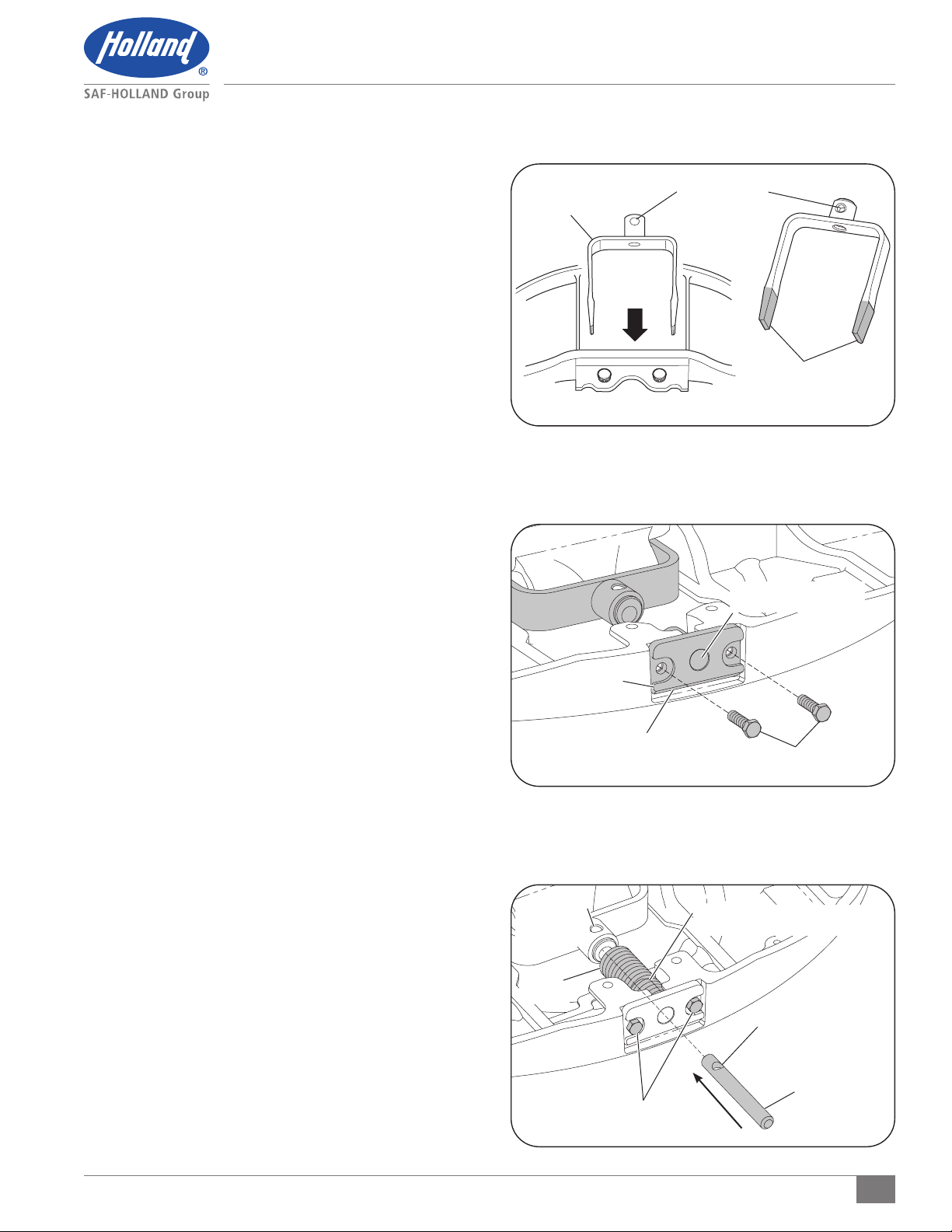

RK-12058 PARTS LIST (XA-351-TT SERIES ONLY)

ITEM DESCRIPTION PART NUMBER QTY

29 Clinch Pin XB-12043 2

30 Bracket Pin XA-12037-P 2

31 Rubber Bushing XB-0011 2

BRACKET COMPONENTS (XA-351-UBT SERIES ONLY)

ITEM DESCRIPTION PART NUMBER QTY

32 Hex Head Cap Screw, 1-1⁄8"-7 x 7" XB-BR-118-C-7 2

33 Lock Washer, 1-1⁄8" XB-E-536 2

34 Rubber Bushing XB-1604-5 2

SERVICE TOOLS

ITEM DESCRIPTION PART NUMBER QTY

36 Kingpin Gauge TF-0110 1

37 Kingpin Lock Tester TF-TLN-5001 1

RK-PKT-5 PARTS LIST (XA-351-TT SERIES ONLY)

ITEM DESCRIPTION PART NUMBER QTY

28a Pocket Insert XD-12026-P 2

35 Double Face Tape XB-09422 4

RK-PKT-2 PARTS LIST (XA-351-UBT SERIES ONLY)

ITEM DESCRIPTION PART NUMBER QTY

28b Pocket Insert XD-08908-P0 2

35 Double Face Tape XB-09422 4

RK-12197 PARTS LIST

ITEM DESCRIPTION PART NUMBER QTY

22 Lock Pin XA-12046-P 2

23 Lock Set XA-08332-1-P 1

24 Lock Pin Washer, 1-1/8" I.D. x 2" O.D. XB-10249 2

25 Lock Nut, M27 x 3 XB-12027 2

26 Lock Spring XB-07628-P 1

27 Never-Seez®(Not Shown) XB-02967 1

Note: Kits available from a local SAF-HOLLAND Distributor.