Dimensions and technical information are subject to change without notice

124

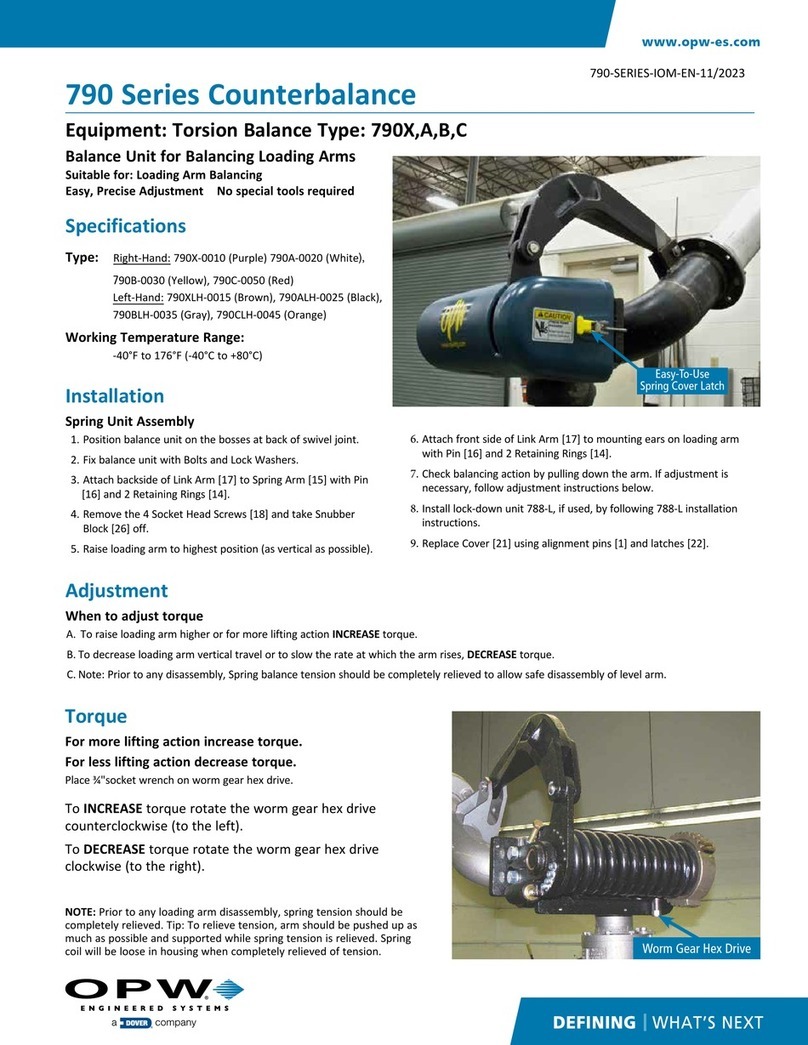

Compliance Devices | Maintenance and Assembly Procedure

CH Series

For more information call us at: 1-800-ROBOHAND or 203-261-5558 Fax: 203-452-7418 Visit us on the Internet at: www.destaco.com

8.55

CH SERIES

MAINTENANCE

Third Angle

Projection

Seal Kit

Items

Thread

Locker

Krytox™

Lubricant

Teflon®Based

Grease

Lightweight

Machine Oil

Super

Bonder

Item Qty Name

1 1 Body

2 1 Piston

3 1 Centering cone

4 1 Cap

5 1 Crossed ring

6 1 Output flange

7 1 Bottom case

8 2 Sleeve

9 4 Key

50 1 O-ring, Cap

51 2 O-ring, Cap

52 4 SS screw, Cap

53 2 SHC screw, Cap

54 1 O-ring, Piston

55 1 O-ring, Piston

56 1 O-ring, Centering cone

57 1 LHC screw, Piston

58 1 Washer, Piston

61 2 Pin, Key

62 2 Pin, Sleeve

65 2 Pin, Body

66 4 SHC screw, Flask

67 6 Spring

NOTE: Contact the Robohand Sales

Department for a complete spare parts

list with order numbers and prices.

Assembly Procedures

1) Press-in the bushing (#8) into the body (#1)

2) Insert the pins (#65) into the body (#1)

3) Lubricate and insert the pins (#62) into the bushings (#8)

4) Lubricate and insert the keys (#9) into the pins (#62)

5) Lubricate and assemble the crossed ring (#5) onto the body (#1).

The keys (#9) have to be positioned into the slots of the crossed ring

6) Insert the pins (#61) into the output flange (#6)

7) Lubricate and insert the keys (#9) into the pins (#61)

8) Assemble the sub assembly output flange and keys on the crossed

ring (#5). The keys (#9) have to be positioned into the slots of the

crossed ring

9) Mount the bottom case (#7) onto the body, positioning with the

pins (#65).

10) Fasten the bottom case (#7) using the screws (#66) with thread locker

11) Insert the O-Ring (#56) into the centering cone (#3)

12) Insert the O-Ring (#54) into the inside groove of the piston (#2)

13) Insert the O-Ring (#55) into the outside groove of the piston (#2)

14) Assemble the piston (#2) with the centering cone (#3). For -RL

option, the piston counterbore holes have to face the body

counterbore holes. Opposite mounting for -RA option.

15) Fasten the centering cone (#3) with the piston (#2) using the

washer (#58) and the screw (#57) with thread locker

16) For –RL option, insert the springs (#67) into the body and piston

counterbore holes.

17) Insert the piston + centering cone sub assembly into the body

18) For –RA option, insert the springs (#67) into the cap and piston

counterbore holes.

19) Insert the O-Ring (#50) into cap groove (#4)

20) Insert the O-Ring (#51) into counterbore holes of the cap (#4)

21) Screw the SS screws into the cap (#4) with thread locker

22) Locate and insert the cap (#4) into the body (#1) using the screws

(52) with thread locker.

66

1

2

3

4

7

6

9

8

5

50

51

52

53

54

55

56

57

58

61

62

65

67

8.1-8.111RED.qxd 2/6/06 10:42 PM Page 55