page 4 of 16

ALFA IN a.s. © www.alfain.eu

cause noise levels to exceed safe limits. You must protect your ears from

loud noise to prevent permanent loss of hearing.

To protect your hearing from loud noise, wear protective ear plugs and/or

ear muffs. Protect others in the workplace.

Noise levels should be measured to be sure the decibels (sound) do not

exceed safe levels.

The operator must ensure all flammable materials are removed from the

work area to avoid any risk of fire.

The operator must NEVER weld containers that have previously

contained petrol, lubricants, gas or similar flammable materials, even if

the container has been empty for a considerable time. THERE IS A

VERY HIGH RISK OF EXPLOSION.

The operator must be aware of all the special regulations which he needs

to conform to when cutting in enclosed spaces with a high risk of

explosion.

To prevent electric shock, we strongly suggest the following rules:

Do not work in a damp or humid environment.

Do not use the machine if its cables are damaged in any way.

Make sure that the earthing system of the electric equipment is

correctly connected and operational.

The operator must be insulated from the metal components

connected to the return wire.

The earthing of the piece being worked could increase the risk of

injury to the operator.

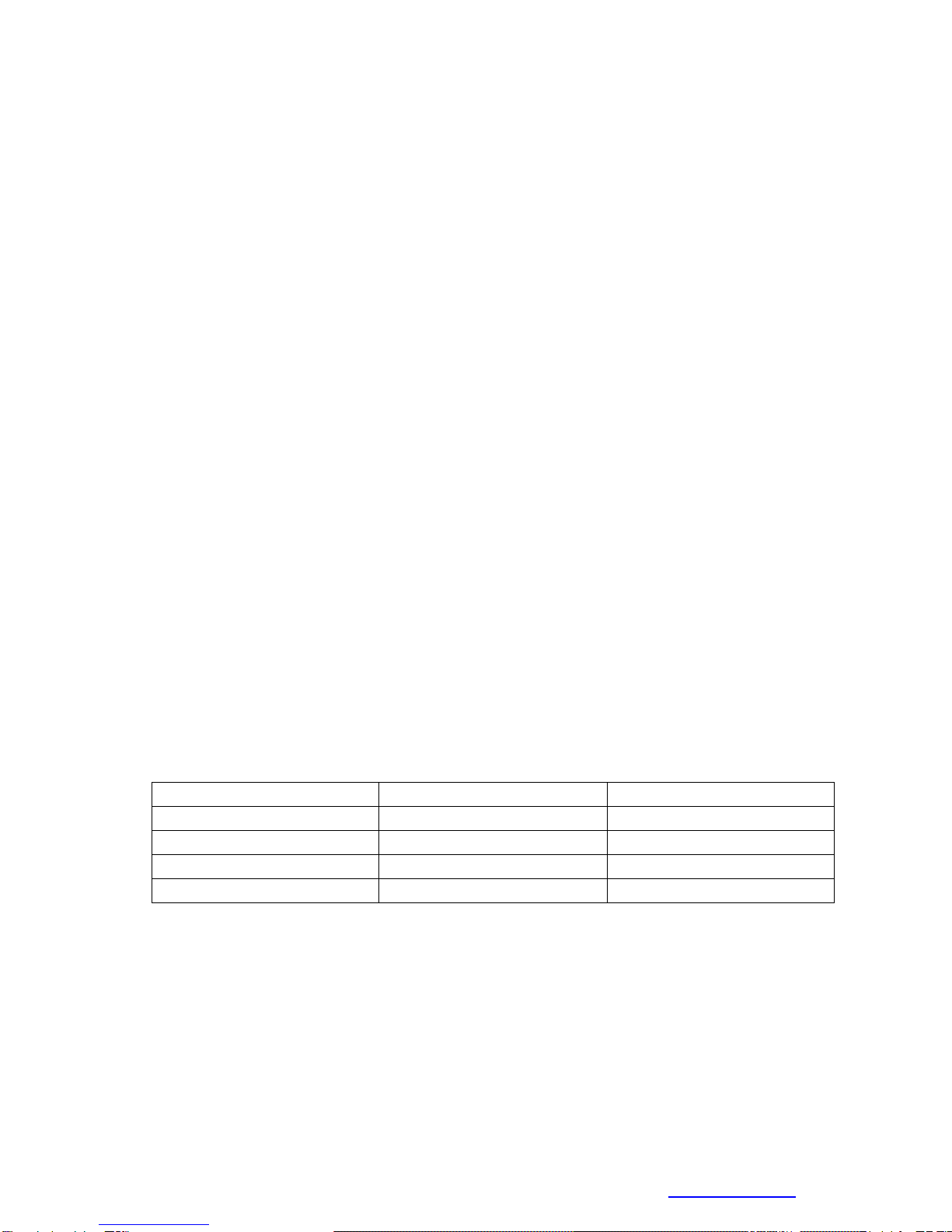

EN 60974-1 Standard: Open-circuit voltage. During the operation of the

machine, the highest voltage, with which it is possible to come into

contact, is the open-circuit voltage between the clamps.

The maximum open-circuit voltage of the plasma machines is established

by national and international standards (EN 60974-1) depending on the

type of current to be used, on its waveform and on the hazards arising

from the work place. These values are not applicable to the strike

currents and those for stabilisation of the arc that could be above it.

The open-circuit voltage, for as many adjustments as possible, must

never exceed the values relating to the various cases shown in the

following table:

Case Working conditions Open-circuit voltage

1 Places with increased

risk of electric shock DC current: 113V

peak value AC current: 68V

peak value and 48V

effective

2 Places without increased

risk of electric shock DC current: 113V

peak value AC current: 113V

peak value and 80V

effective

3 Torches held DC current: 141V AC current: 141V