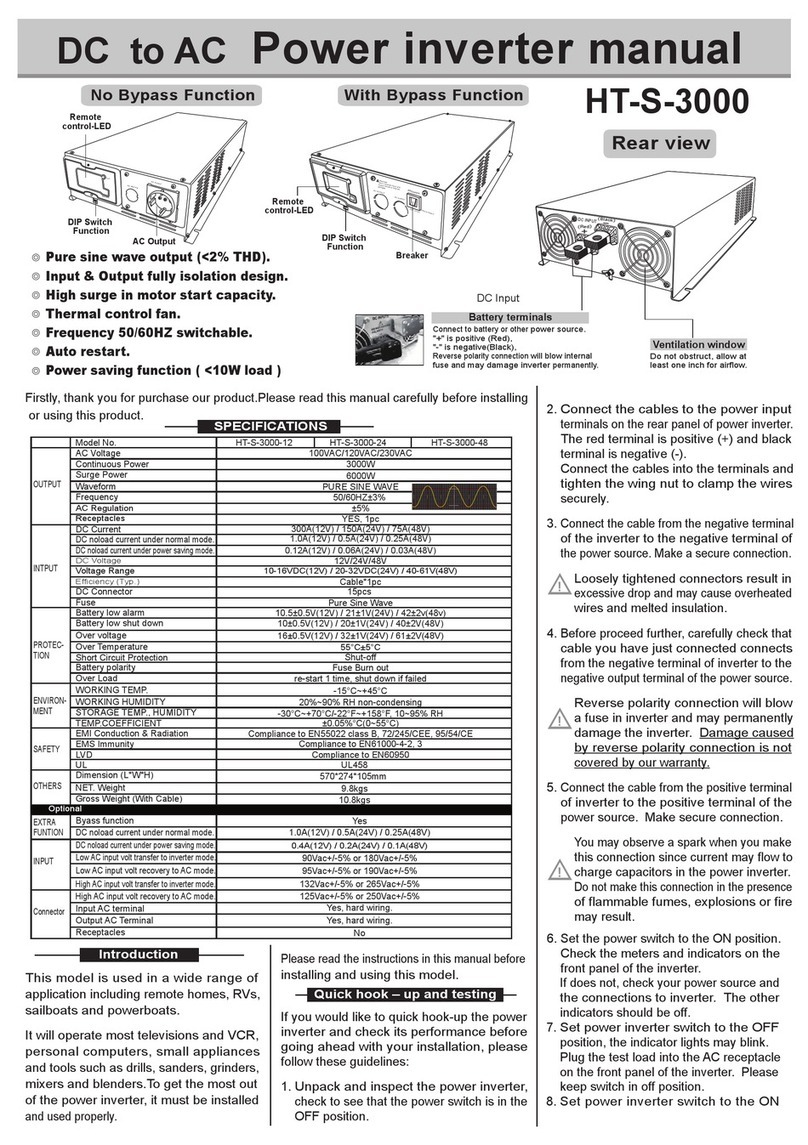

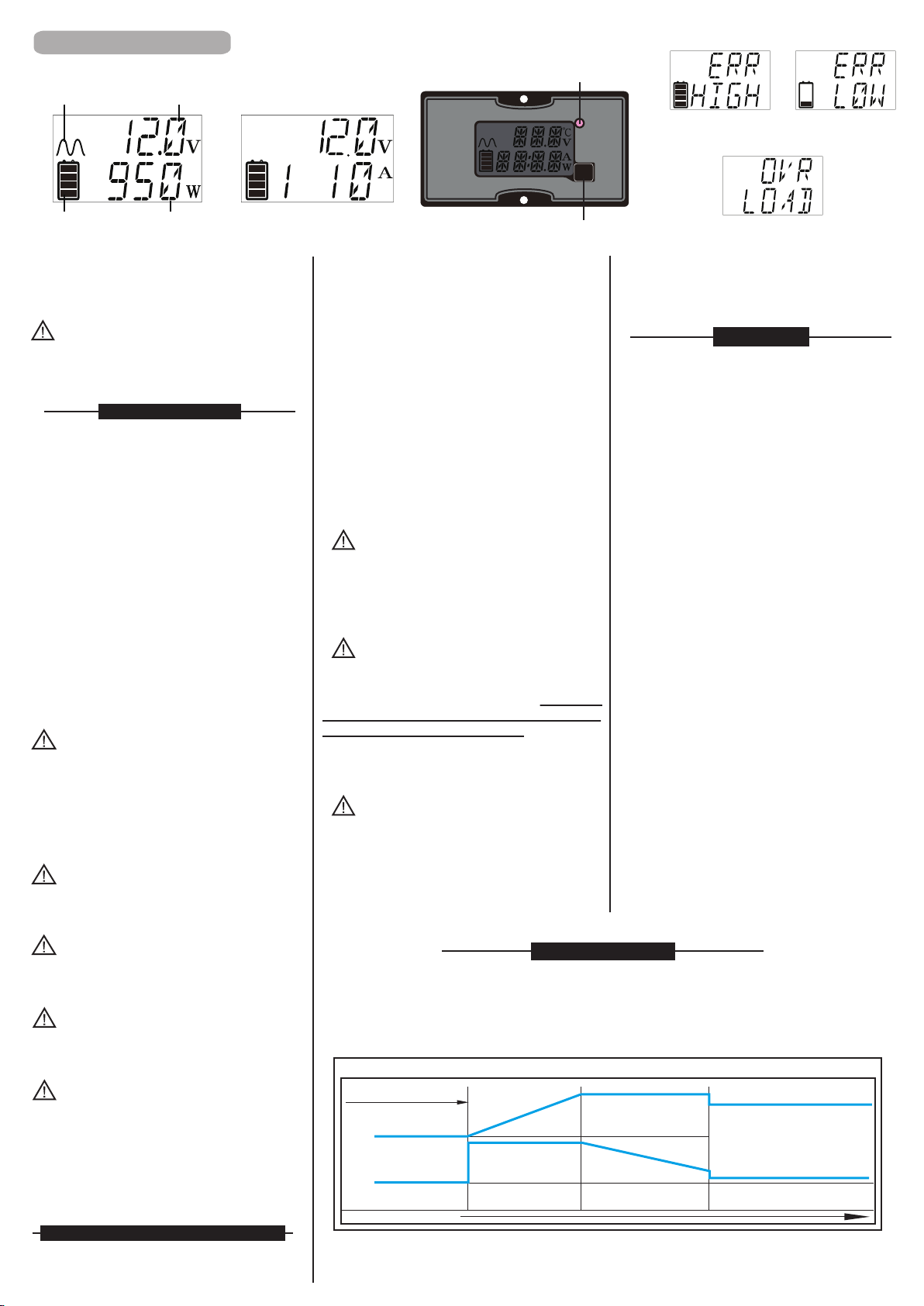

fault LED Indicator

Remote control-LCD

Power LED

Waveform

Battery volt

Load watts

Battery capacity

High battery

volt protection. Low battery

volt protection.

Over temperature / Overload

If you would like to quick hook-up the power inverter/

5.

Connect the cable from the positive terminal

of inverter/charger tothe positive terminal of

the power source. Make secure connection.

WARNING!!

You may observe a spark when you make this

connection since current may flow to charge

capacitors in the power inverter.

Do not make this connection in the presence

of flammable fumes, explosions or fire may

result.

If you would like to quick hook-up the power inverter/

charger and check its performance before going

ahead with your installation, please follow these

guideline.

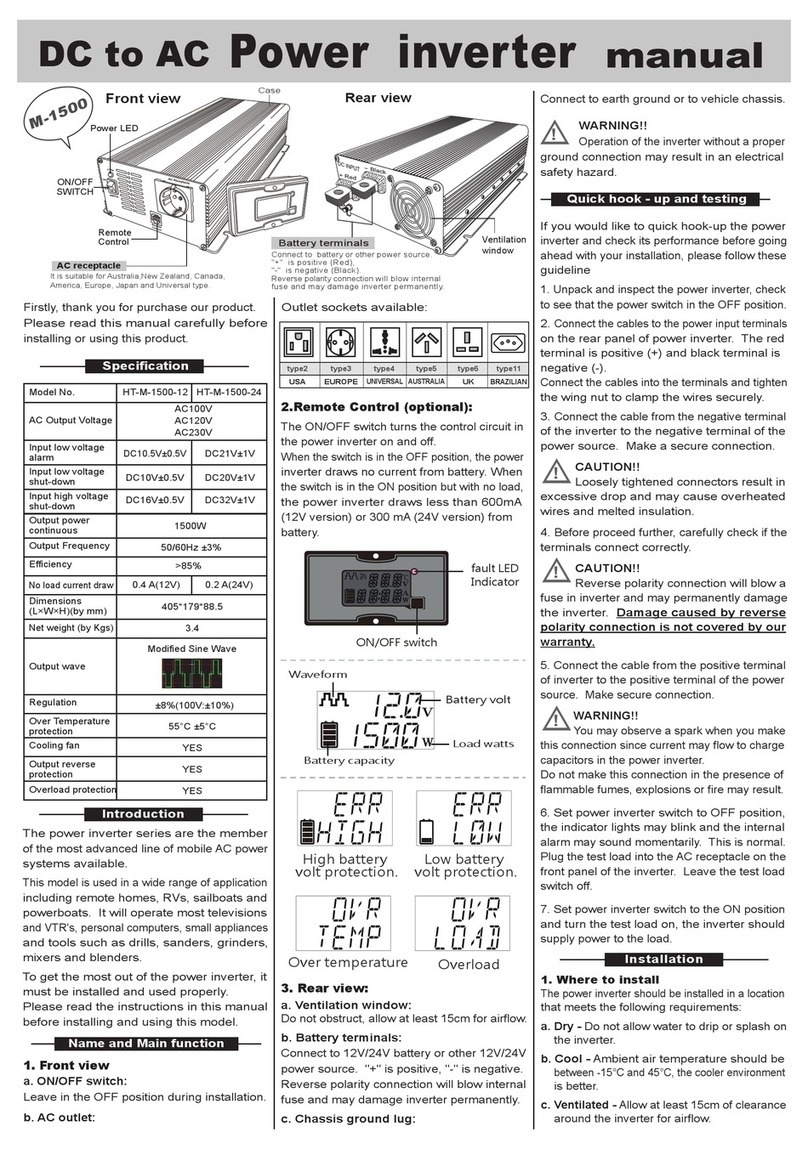

1.

Unpack and inspect the inverter/charger, check

to see that the power switch in the OFF position.

2.

Connect the cables to the power input terminals

on the rear panel of inverter/charger. The red terminal

is positive (+) and black terminal is negative (-).

Connect the cables into the terminals and tighten

the wing nut

to the wires securely.

3.

Connect the cable from the negative terminal

of the inverter/charger tothe negative terminal

of the power source. Make a secure connection.

CAUTION!!

Loosely tightened connectors result in

excessive drop and may cause overheated

wires and melted insulation.

4.

Before proceed further, carefully check if

the terminals connect correctly.

CAUTION!!

Reverse polarity connection will blow a fuse

in inverter/charger and may permanently

damage the inverter/charger. Damage

caused by reverse polarity connection is

not

covered by our warranty.

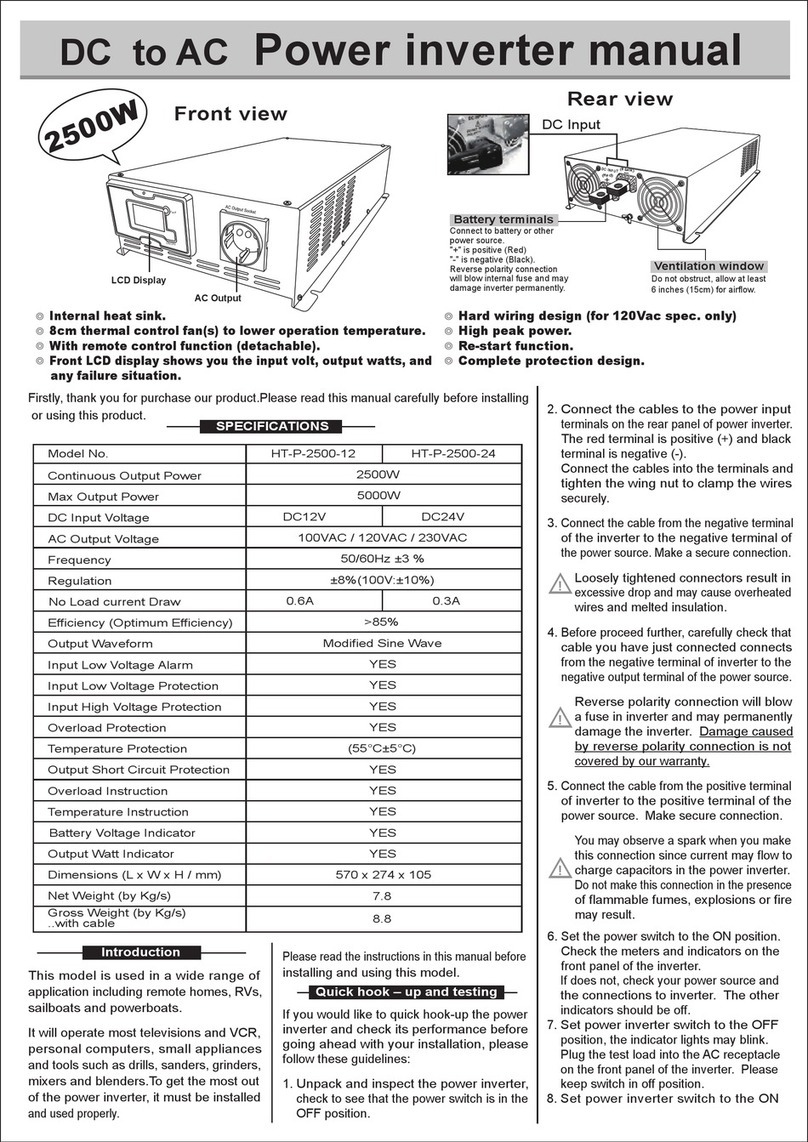

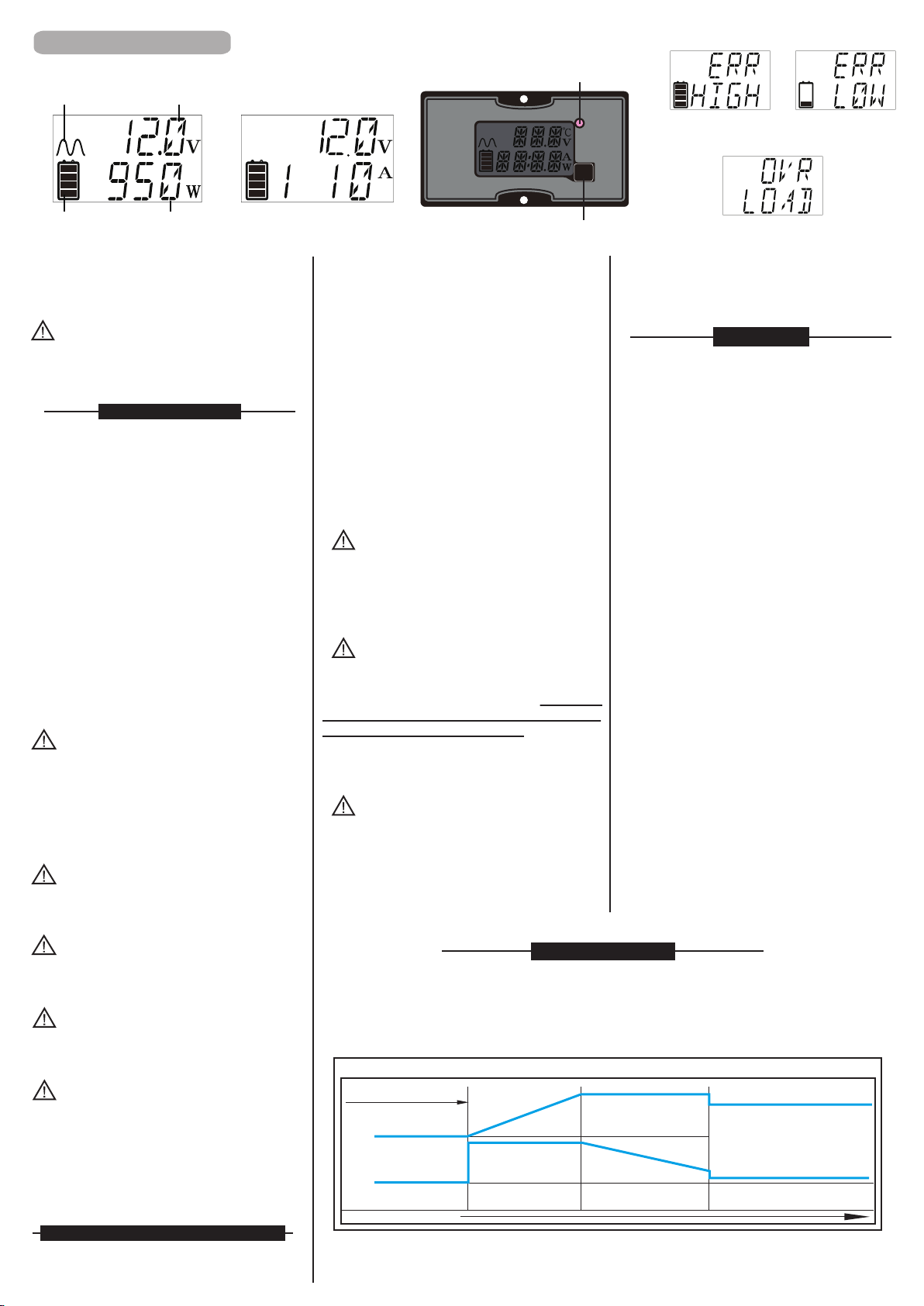

charger status display

For lead-acid and lead-calcium batteries only.

Stage1: Bulk Charge Max 14.5±0.5V, 10A.

Stage2: Absorption Charge 14.5±0.5V, 10~1A.

Stage3: Float Charge 13.6±0.5V, min. 0.5A.

Battery Charger

Charging started

Multistage Battery Charger

DC Voltage

DC Current

Time

Bulk stage

Constant current

at maximum

charge rate

Absorption stage

Constant voltage

at Absorption

voltage setting

Float stage

Constant voltage

at the Float

voltage setting

Load current on demand

Charger LED

Indicator Red Red Orange

your Amp-hour consumption between charging

cycles and use a battery bank with twice that

capacity.

To calculate Amp-hour consumption first look

at the rating plate on your AC appliance or tools.

Each appliance or tool will be rated in either

AC Amps or AC watts or AC VA (Volts-Amps)

apparent power.

Use one of the following formulas to calculate

the DC Amp-hour draw for a 12 Volt system:

(AC Amps x 10) x 1.1 x hours of operation

= DC Amp-hours

(AC watts/12) x 1.1 x hours of operation

= DC Amp-hours

(AC VA/12) x 1.1 x hours of operation

= DC Amp-hours

6. Set power inverter switch to the ON position

and turn the test load on, the inverter should

supply power to the load.

To achieve 50% cycling you should calculate

Batteries

Calculate the above for every AC appliance or

tool you intend to use on your inverter. This

will give you the total number of Amp-hours

used between recharges. Size your battery bank

using this number as a guideline.A good rule

to follow is to size the battery bank about 2times

larger than your total Amp-hour load requirement.

Plan on recharging when 50% discharged.

Many electric motors have monentary starting

requirements well above their operational rating.

Start up watts are listed where appropriate.

lndividual styles and brands of appliances may

vary.

In all formulas, 1.1 is the factor for inverter/charger

efficiency.

Quick hook - up and testing

compartment, overheating may result.

CAUTION!!

Risk of electrical shock. Both AC & DC voltage

sources are existed inside this equipment.

Each circuit must be individually installed.

CAUTION!!

Risk of electrical shock. Do not remove

cover, no user serviceable parts inside.

Refer servicing to qualified service personnel.

APPLICATION INFORMATION:

Provided with integral electronic protection

against AC & DC overloads.

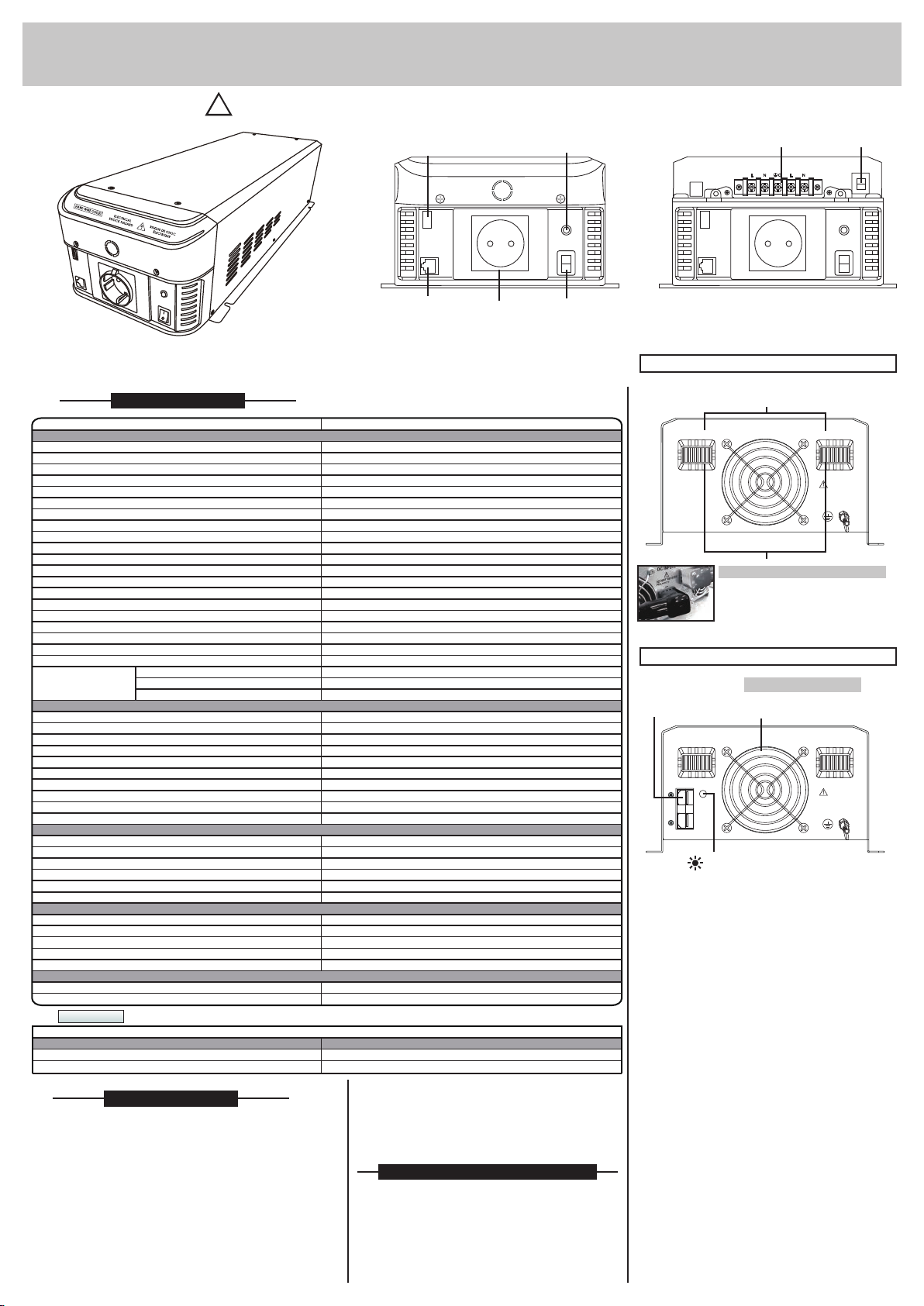

Installation

1. Where to install

The inverter/charger should be installed in a

location that meets the following requirements:

a. Dry - Do not allow water to drip or splash

on the inverter/charger.

d. Safe - Do not install the inverter/charger

in the same compartment as batteries or

in any compartment capable of storing

flammable liquids such as gasoline.

CAUTION!!

This equipment is not ignition protected and

employs components that tend to produce

arcs or sparks. To reduce the risk of fire or

explosions, do not install in compartments

containning batteries or flammable materials

or areas in which ignition protected equipment

is required.

CAUTION!!

To reduce the risk of electric shock and

prevent premature failure due to corrosion,

do not mount where exposed to rain or spray.

CAUTION!!

To prevent fire, do not obstruct ventilation

openings. Do not mount in a zero clearance

c.

Ventilated - Allow at least 3 inch (15cm)

of clearance around the inverter for airflow.

Ensure the ventilation openings on the rear

and bottom of the unit are not obstructed.

b.

Cool - Ambient air temperature should

be between -15°C ~ 45°C, the cooler

environment is better.

Reverse polarity connection will blow internal

fuse and may damage inverter/charger

permanently.

WARNING!!

Operation of the inverter/charger without a

proper ground connection may result in an

electrical safety hazard.