Honeybee AirFlex SDX User manual

200 Series & SDX

Quick Start Guide

2019

®

This guide is a supplement to the operators manual, do

not aempt to operate your equipment without rst

reading and understanding the full operator manual.

When you exit the combine, shut o the combine,

engage the parking brake, and wait for all moving parts

to come to a complete stop before approaching the

header.

If working on a raised header, ensure the feeder house

cylinder locks are in place.

Do not wear loose clothing or jewelry around moving

parts.

Avoid high pressure hydraulic spray. Seek medical

aenon immediately if it punctures your skin.

Ensure all equipment is secured against sudden drops.

Read and understand all safety instrucons in the

operator manual before proceeding.

Revision 1.2 P/N: 95111

Document Revision History

Revision Author Date Description

1.0 AD 05/26/2019 Document Created

1.1, 1.2 AD 05/29/2019 Spelling corrected, removed mention of upper stop bolt on

auger drum.

Page 3 Revision 1.2 P/N: 95111

Honey Bee Manufacturing Ltd.

AirFLEX 200 Series & SDX Header - Quick Start Guide

Header Preparaon

Raise front reel bats to

operaonal posion and

secure to the control arms

using the preinstalled nut and

bolt.

Remove and store the e-down brackets located

on the transport mounng bracket and strut on

the le side of the header.

Reinstall the ngs which secure the paddle pivot

pin.

Remove the wire holding the reel arms

and reel in place. Inspect thoroughly as

the wires can be in mulple locaons.

Ensure dividers are

securely installed

Secure divider with bolt.

Secure divider with handle.

Page 4 Revision 1.2 P/N: 95111

Honey Bee Manufacturing Ltd.

AirFLEX 200 Series & SDX Header - Quick Start Guide

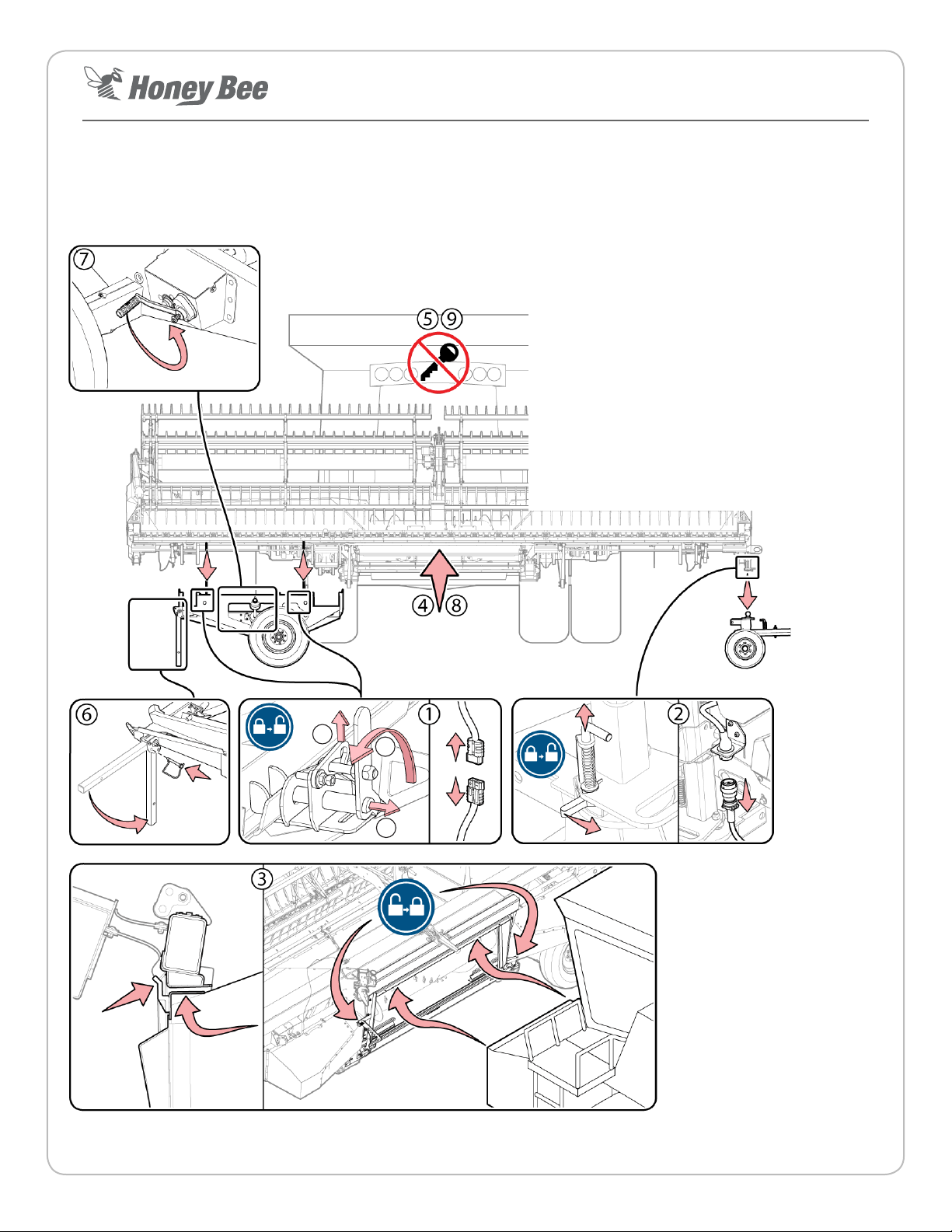

Mounng the Header 1 Release the two transport cart locks and disconnect

the cart’s electrical harness.

2 Release the draw bar lock and disconnect it’s

electrical harness.

3 Slowly drive the combine forward unl the feeder

house is inserted into the feeder house opening.

Ensure it is properly aligned

4 Slowly li the header 1-2 feet above its current

posion to release the transport cart & drawbar.

5 Shut down the combine, engage the parking brake

and engage the feeder house locks.

6 Lower the transport cart support bar and secure pin.

7 Lower the trasport cart with the hand crank and

unhook the straps from the header.

8 Raise the header and back away from the cart,

lower the header back down to a working height.

9 Shut down the combine, engage the parking brake

and engage the feeder house locks.

AB

C

Page 5 Revision 1.2 P/N: 95111

Honey Bee Manufacturing Ltd.

AirFLEX 200 Series & SDX Header - Quick Start Guide

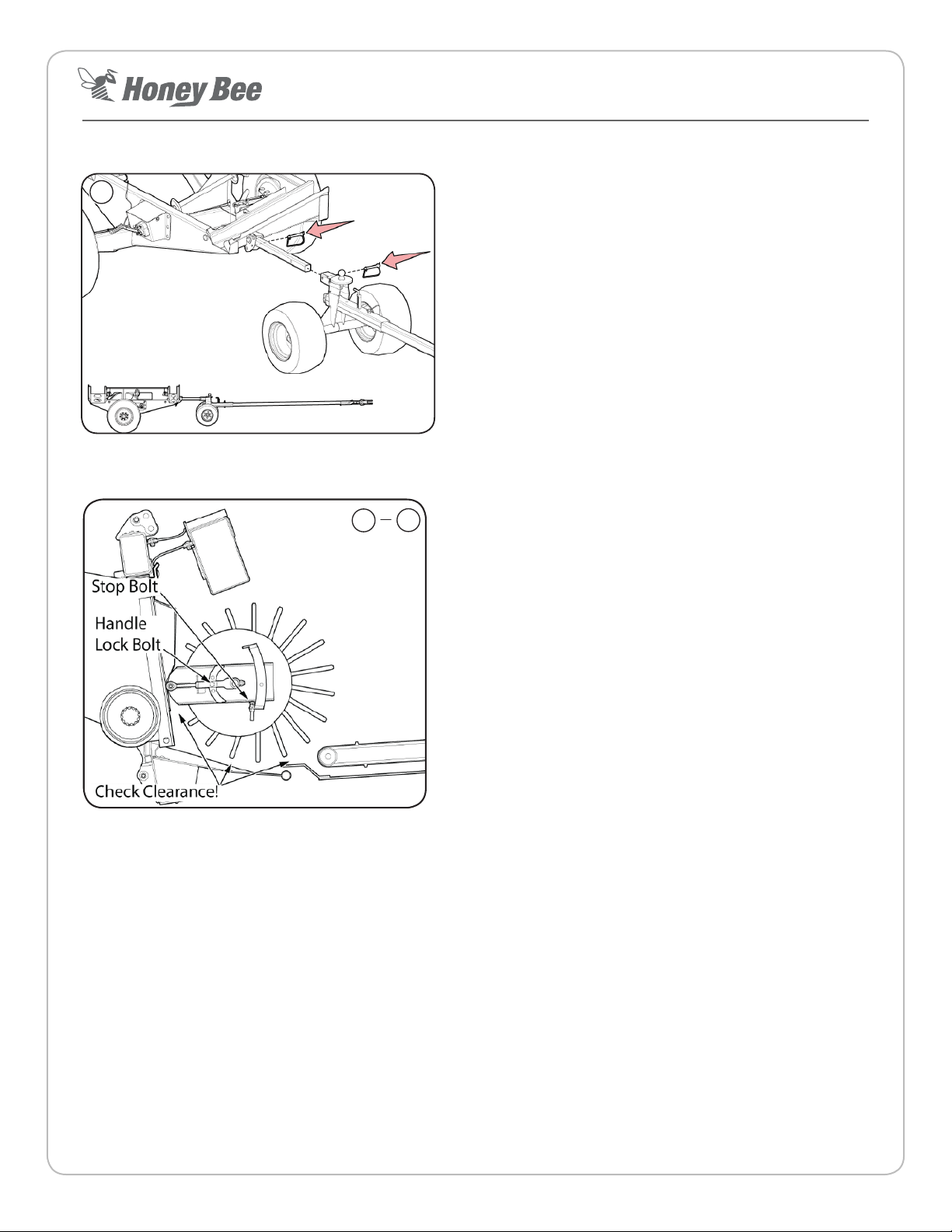

Secure the transport cart and draw bar cart together, secure

with pins as illustrated and place in a storage locaon.

Evenly adjust the le and right eye bolts on the feed auger drum

so it is moved to within 1/2”(1.3 cm) of the combine feeder

house protrusions.

Set the feed auger drum lower stop bolts to prevent the drum

from contacng the rest of the header.

Rotate the auger drum by hand to ensure it will not contact the

protrusions, ghten the lock nuts on the eye bolts.

Set Feed Auger nger ming so the feed auger ngers maintain

adequate clearance from the components surrounding the feed

auger drum.

Check All Clearances around the feed auger drum and adjust

accordingly.

10

Finish Mounng

11 15

Page 6 Revision 1.2 P/N: 95111

Honey Bee Manufacturing Ltd.

AirFLEX 200 Series & SDX Header - Quick Start Guide

Make Connecons

1 Turn o the combine’s master baery switch.

2 Make the hydraulic and electrical

connecons at the mulcoupler

located on the le side of the

feeder house. Connect both

drive shas to the combine.

3 Starng at the front of the combine, route

the automax harness under the combine

cab and inside. Connect to the automax

display. Route the remianing poron of the

harness to the combine’s baery. Connect

the harness to the power system aer the

power switch to ensure the Automax does

not drain the baery when the combine is

turned o.

Ensure enough slack is le in the electrical

harness at the feeder house pivot for it to go

through its full range of moon.

Page 7 Revision 1.2 P/N: 95111

Honey Bee Manufacturing Ltd.

AirFLEX 200 Series & SDX Header - Quick Start Guide

Header Setup Overview

1. Ensure each sensor ‘ag’ contacts its roller at the ‘heel’

of each strut at the rear of the header. The Flag should

contact the center of the roller. The two outermost sensor

tabs should be rmly in contact with their rollers while the

remaining tabs should only lightly touch their rollers. This

ensures the system reacts to input from the outer ends of

the header rst.

Roller

Flag

2. Verify the header height sensor voltages on the

AutomaxLite display:

RIGID mode header height control only pertains to the 200

series header. RIGID header height control sensors are not

installed on the SDX and therefore informaon about RIGID

sensors in this quick start guide can be ignored for the SDX

plaorm.

• In FLEX Mode: With the header air system pressurized

to approximately 30 psi, the sensor voltages should

range between 1.5 and 3.5 volts through the cuer

bar’s full range of moon.

• RIGID Center Subframe Sensing Mode (default from

factory): With the header air system pressurized to

approximately 90 psi, the sensor voltages should

range between 1.5 and 3.4 volts through the subframe

sensor’s full range of moon.

• RIGID Divider Mode (must be acvated by swapping

sensor wires and unlocking dividers as described

in operator manual): With the header air system

pressurized to approximately 100 psi, the sensor

voltages should range between 1.5 and 3.5 volts

through the divider’s full range of moon.

Note: Refer to operator manual for detailed instrucons.

IMPORTANT: Don’t make assumpons, don’t skip steps, x all

errors that occur before connuing.

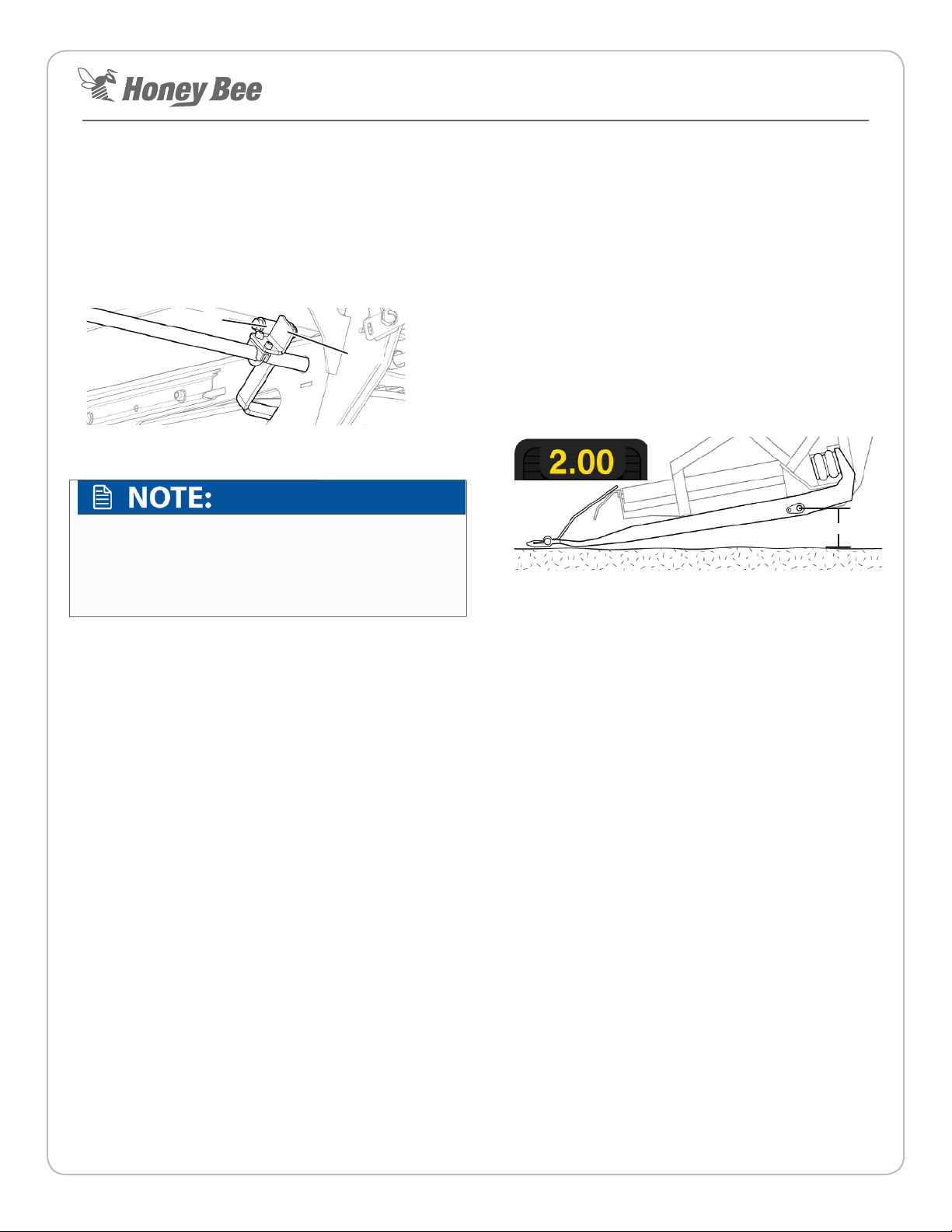

Set combine feeder house angle.

The Combine Feeder House must be lted at a specic angle

for opmal header operaon. To set proper operaon angle.

1. Park the combine and header on a rm level surface.

2. Set the header to FLEX mode and lower the air pressure

unl 30psi is reached.

3. Fully retract the hydraulic lt cylinder.

4. Lower the table unl the cuer bar is fully pushed up.

5. Slowly raise the header unl 2.00 volts (8 bars) show on the

sensor bar graph on the Automax Lite display

6. Measure down to the ground from the pivot point of the

outer-most paddle. There should be an 6-7” (15.4 - 17.8 cm)

space when at the opmal feeder house angle.

6-7” (15.2-17.8 cm)

• If the paddle ‘heel’ is more than 6-7” (15.2 - 17.8 cm)

above the ground, the feeder house is lted too far

forward and the cuer bar guards will dig into the

ground.

• If the paddle ‘heel’ is less than 6-7” (15.4 - 17.8 cm)

above the ground, the feeder house is not lted

forward enough and the rear of the paddle will drag on

the ground. 6-7” (15.2-17.8 cm)

7. Adjust the feeder house angle as necessary and re-test the

angle as outlined in the previous steps. Tilt can be adjusted

to suit ground condions and habits of the operator.

Page 8 Revision 1.2 P/N: 95111

Honey Bee Manufacturing Ltd.

AirFLEX 200 Series & SDX Header - Quick Start Guide

Combine Calibraon

1. The combine must be run at maximum RPM (harvest

speed) and the hydraulic oil must be up to operang

temperatures during calibraon.

2. Check the oil level to ensure there is no air in the system

(normally heard as a whining noise).

3. Set the AIRFLEX via the AutoMax Lite monitor to RIGID

mode if cung o the ground or FLEX mode if cung on

the ground.

4. Set combine hydraulic header raise rate so it takes 6

seconds to li the header from the lowest posion to the

highest posion.

5. Set combine hydraulic header drop rate so it takes 7

seconds to lower the header from the highest posion to

the lowest posion.

6. Refer the 200 Series/SDX operator’s manual for specic

instrucons on calibrang in each mode. Calibrate the

combine’s header height sengs as described in the

combine’s operator manual.

7. Slowly increase header height sensivity via combine

controls unl the header starts hunng up and down.

Decrease sensivity by 10-20% unl the header stops

hunng. Set the lt sensivity to half the height sensivity

minus 10%, so if the header height sensivity is set to 200,

the lt sensivity should be set to approximately 90 (200/2

= 100, 100 - 10% = 90).

8. When the combine calibraon is done, lower and run

the header and combine rotor so automac header

height is enabled. Record a set-point for header height

on the combine (i.e. 4” (10 cm)). Raise the table all the

way up and laterally lt it all the way to the le or right.

Press the return to set point buon on the combine.

The header should lower back to the set point AND level

out automacally. If this fails, it may indicate a combine

soware problem.

The combine specic sengs listed on the following

pages are recommendaons only. Opmal sengs will

vary by equipment conguraon and condions. It is

the equipment operator’s responsibility to ensure they

operate their equipment in a safe, ecient manner.

Reel Setup

Set the pitch of the reel ngers via the adjuster at the end of

the reel. The middle posion is a good place to start. If crop is

wrapping around the reel, set a less aggressive nger pitch.

Ensure the reel is level and that the reel ngers maintain

a minimum distance of 1-1/2” (3.8cm) from the cuer

bar. Adjust the reel height adjustment bolts located on the

underside of the reel arms if necessary.

Calibraon Troubleshoong:

Check that the combine is receiving the correct sensor voltages

from the header sensors.

Verify the correct combine sengs have been entered.

Inspect crop dividers, metal should contact metal if they are

lied and dropped. If the springs are too ght, the dividers

will ride up.

If header is not reacng quick enough, sensivies may

need to be increased. If header is hopping or jumping then

sensivies may need to be decreased.

Page 9 Revision 1.2 P/N: 95111

Honey Bee Manufacturing Ltd.

AirFLEX 200 Series & SDX Header - Quick Start Guide

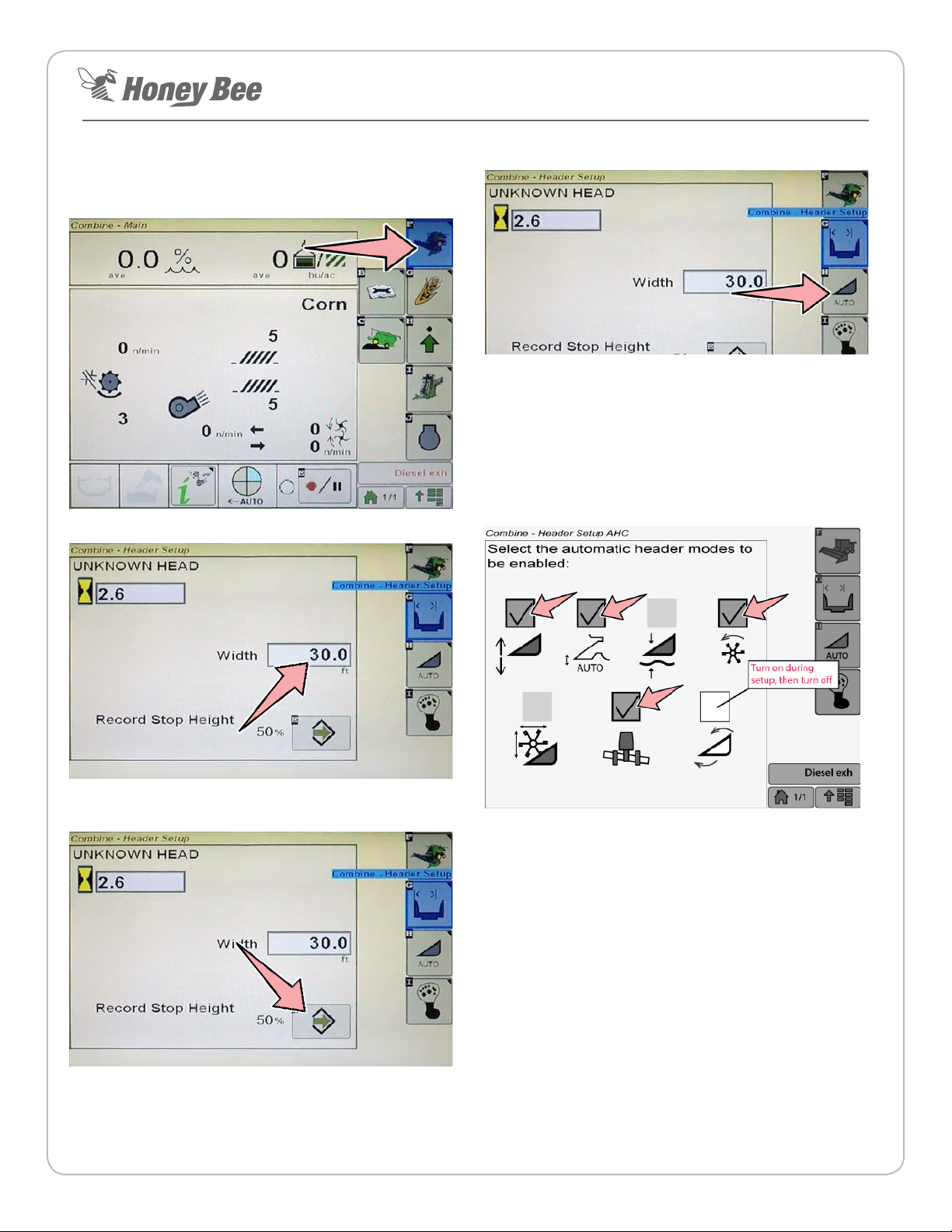

John Deere S550 and S600 Series Combines

1. Enter the combine’s header setup screen by selecng the

header icon.

2. Set the header width.

3. Raise the header to 60% of it’s maximum height and press

the enter buon to save the value.

4. Select the Auto Header screen via the AUTO buon.

5. Ensure the following boxes are checked:

• Header Height Control

• Auto HHC

• Auto reel speed

• Auto lt

• During setup, faceplate angle must be set.

Page 10 Revision 1.2 P/N: 95111

Honey Bee Manufacturing Ltd.

AirFLEX 200 Series & SDX Header - Quick Start Guide

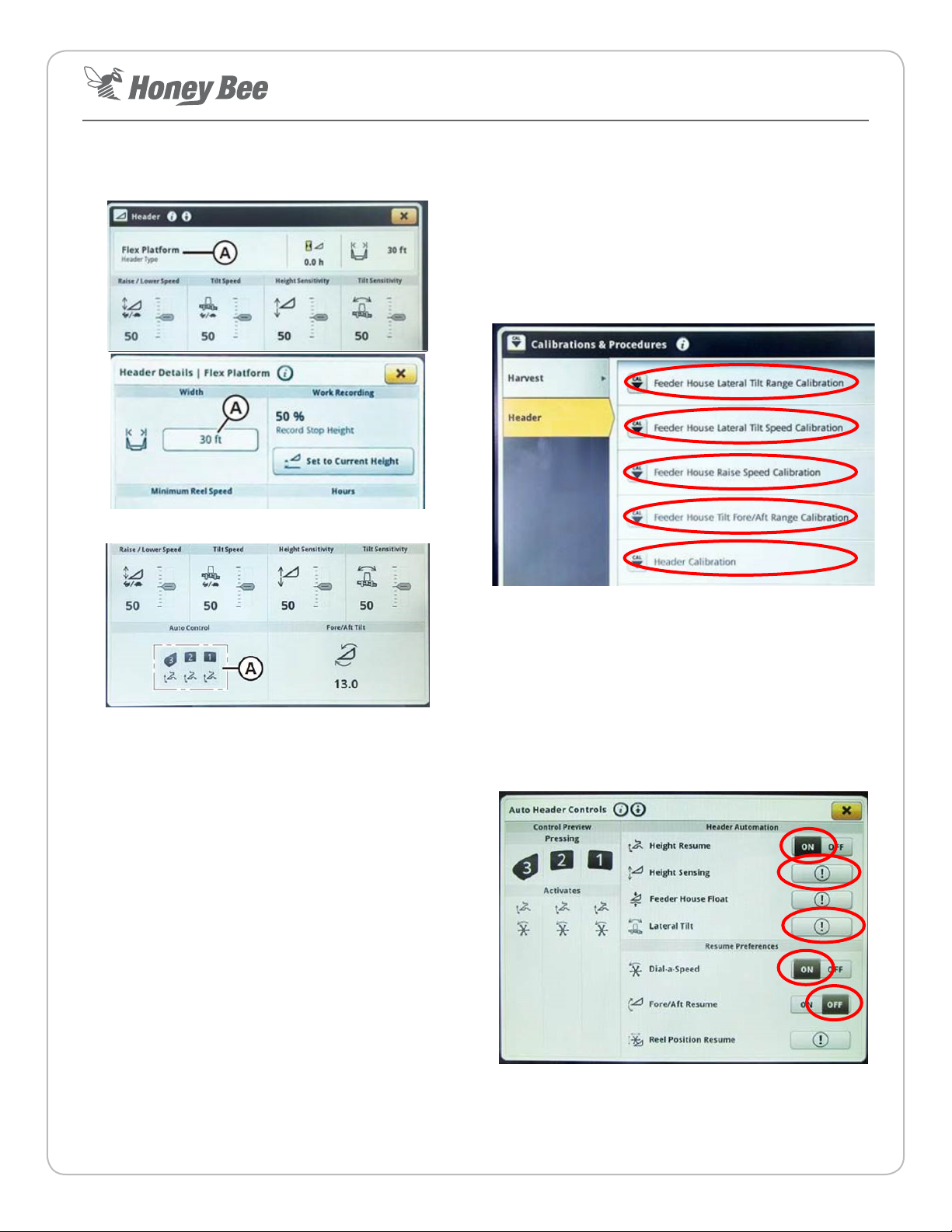

John Deere S700 Series Combines

1. Set the header width via the header screen

2. Select the Auto Contour icon (A) to get to setup screen.

3. The following calibraons must be peformed starng at

the top of the list and working your way down:

• Feeder House Lateral Tilt Range Calibraon

• Feeder House Lateral Tilt Speed Calibraon

• Feeder House Raise Speed Calibraon

• Feeder House Tilt Fore/A Range Calibraon

• Header Calibraon (Must be performed last)

4. Once all the calibraons are done (including the header

calibraon) then the Header Automaon sengs can be

set. Then set the following sengs on the Auto Header

Controls screen:

• Height Resume: On

• Height Sensing: Acvate

• Lateral Tilt: Acvate

• Dial-a-Speed: On

• Fore/A Resume: O

This manual suits for next models

1

Table of contents

Other Honeybee Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions