1. Before adjusng oat spring adjustment bolts (A), rotate spring locks (B) by loosening

bolts (C).

2. To increase oat (decrease header weight), turn both adjustment bolts (A) on the le

side clockwise. Repeat the adjustment at the opposite side.

3. To decrease oat (increase header weight), turn le side adjustment bolts (A)

counterclockwise. Repeat the adjustment at the opposite side.

IMPORTANT:

Ensure the torque wrench indicator readings are equal on both sides of the oat

module.

NOTE:

For FD140 and FD145 double-knife headers, set the oat as described above, then

loosen the right side oat spring bolts two full turns.

NOTE:

If the adequate header oat cannot be achieved using all available adjustments, an

oponal heavy duty spring is available. See your MacDon Dealer or refer to the parts

catalog for ordering informaon.

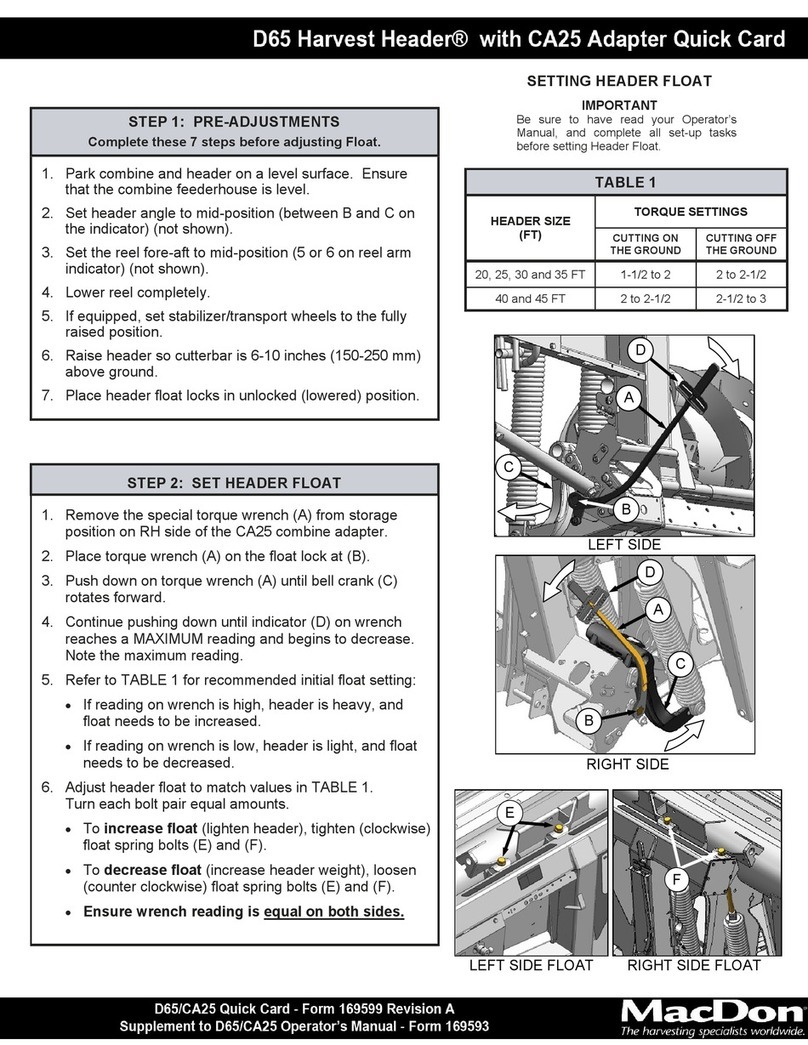

Step 4: Seng Header Float

1. Place torque wrench (A) onto oat pivot (B). Note the change in wrench orientaon

when checking the oat module’s le and right sides.

2. Push down on torque wrench (A) to rotate bell crank (C) forward.

3. Connue pushing down on the torque wrench unl wrench indicator (D) reaches a

maximum reading and then begins to decrease. Note the maximum reading.

4. Repeat the above steps for the opposite side of the oat module.

5. Refer to Table 1.1 as a guide for the oat sengs.

If the reading is high, the header is heavy.

If the reading is low, the header is light.

Step 3: Checking Header Float

Header Model

Indicator Reading

Cung on

the Ground

Cung o

the Ground

FD125, FD130, and FD135 1 1/2 to 2 2 to 2 1/2

FD140 and FD145 2 to 2 1/2 2 1/2 to 3

Table 1.1: Float Sengs

Figure 6: Checking Float – Le Side Shown

Figure 5: Checking Float – Right Side Shown

IMPORTANT:

Torque sengs in Table 1.1: Float Sengs are the recommended header oat sengs. If

necessary, adjust the oat values to suit the crop and eld condions.

1. Remove the wing balance linkage cover on the le side of the oat module by removing

the securing bolt, and rotang the cover upwards unl the inboard end can be lied o.

2. Place the wing lock spring handles in the unlocked (lower) posion.

3. Place torque wrench (A) on bolt (B).

4. Check that pointer (C) is properly posioned as follows:

a. Use torque wrench (A) to move the bell crank unl lower edge of bell crank (D) is

parallel to lower edge of top-link (E).

b. Ensure pointer (C) is aligned with top-link (E). If necessary, bend the pointer so it

aligns with bolt hole (J).

5. Move the wing upward with torque wrench (A) unl the pointer’s lower alignment tab (F)

lines up with the upper edge of top-link (E). Refer to Figure 8. Record the reading on

torque wrench indicator (G).

6. Move the wing downward with torque wrench (A) unl the pointer’s upper alignment

tab (H) lines up with the lower edge of top-link (E). Refer to Figure 9. Record the reading

on torque wrench indicator (G).

7. Check the wing balance on the opposite side of the header.

If the dierence between the readings is 0.5 or less, the wing is balanced and

adjustment is not required.

If the dierence between the readings is more than 0.5, the wing is not balanced and

adjustment is required.

Step 5: Checking Wing Balance

1. Place torque wrench (A) on bolt (B) on the le side of the header.

2. Loosen clevis bolt (C) and jam nut (J).

3. Recheck the wing balance. Refer to Step 5: Checking Wing Balance.

4. If necessary, make the following adjustments:

If the wing is too heavy, turn clevis adjuster bolt (D) clockwise to move clevis (E)

outboard (F).

If the wing is too light, turn clevis adjuster bolt (D) counterclockwise to move clevis (E)

inboard (G).

5. Adjust clevis (E) posion (if necessary) unl the dierence between the torque wrench

indicator readings is 0.5 or less. Tighten clevis bolt (C) and jam nut (J).

6. Place wing lock spring handles (H) in the locked (upper) posion. If the lock doesn’t

engage, move the wing up and down with torque wrench (A) unl it locks. When locked,

there will be some movement in the linkage. Repeat on the opposite side of the header.

7. If the cuerbar is not straight when the wings are in lock mode, then further adjustments

are required. Contact your MacDon Dealer.

8. Return torque wrench (A) to its storage locaon on the oat module frame.

Step 6: Adjusng Wing Balance

IMPORTANT:

Before proceeding, the header oat must be set properly. Refer to Step 4: Seng Header Float.

Figure 8: Wing Balance Linkage,

Wings Set too Light – Le Side Shown, Right Opposite

Figure 10: Wing Balance Linkage – Le Side Shown

Figure 9: Wing Balance Linkage,

Wings Set too Heavy – Le Side Shown, Right Opposite

Figure 7: Float Adjustment Bolts – Le Side Shown