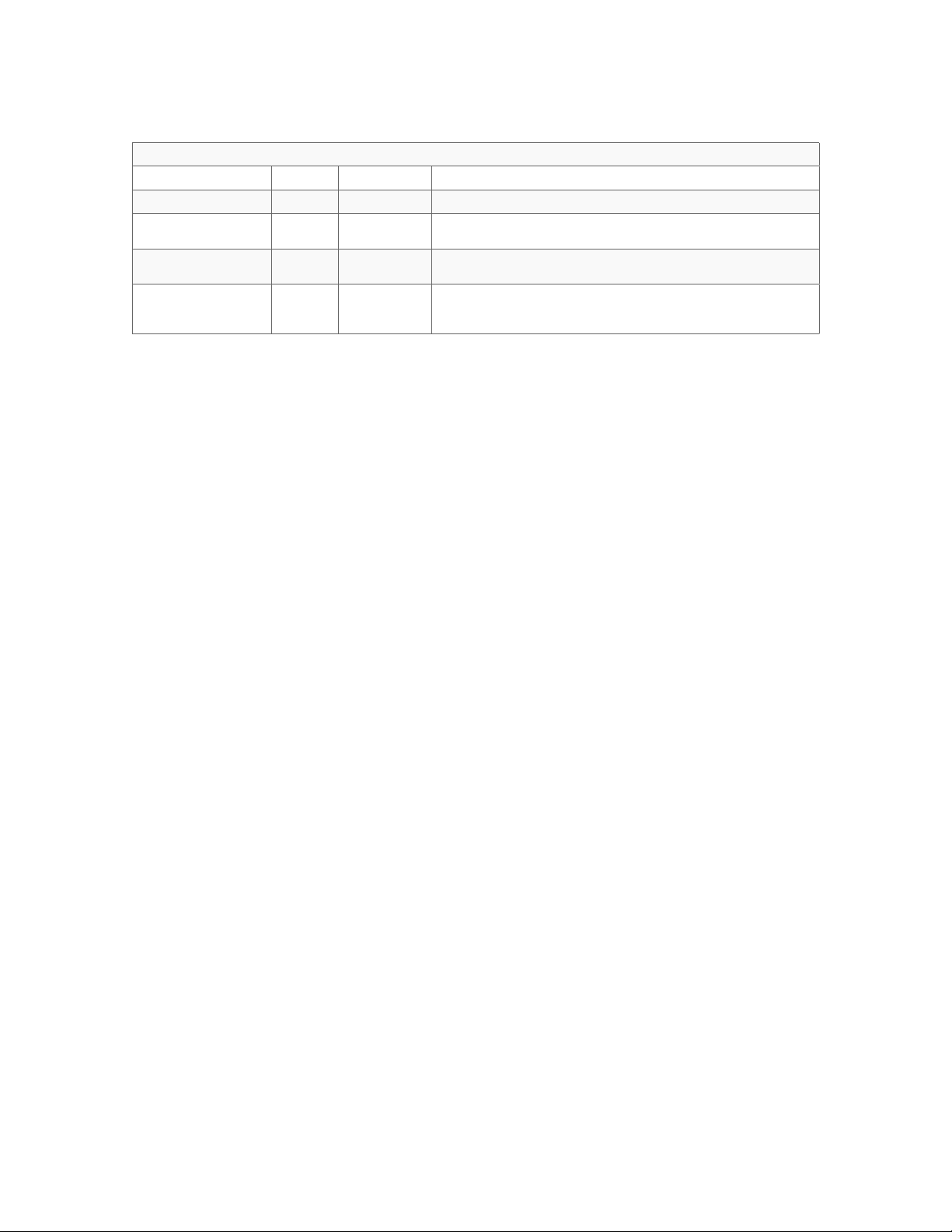

___Set front reel bats to operational position (reinstalled from transport position). - page 31

___Remove reel tie-downs installed from factory.

___Install crop dividers & extensions and secure in place.- page 31

___Check draper tension as per decal on back panel. Adjust if necessary. - page 104

___Walk around the header, checking belts, bolts and shields to ensure everything is tight and in good working order.

Install Automatix harness on the combine, note if the electrical system is positively or negatively switched, hook up the battery

___leads accordingly. - page 35

___Install Automatix control panel in combine cab & connect to electrical harness. - page 35

___Unlock the transport cart and draw bar, lift header with the combine then remove the cart and draw bar. - page 32

___Attach multicoupler and electrical connection(s) - page 34

___Attach the drive shafts to the left and right hand sides of the combine feeder house. - page 34

___Check the clearance between the feed auger drum, stripper plate and feeder house. - page 43

___Check feed auger nger timing, ensure adjustment arm is in middle hole with ngers in fully forward position. - page 43

___Set combine type via automatix control panel - page 39

___Set the faceplate angle using adjustment bolts on the combine’s feeder house (if possible) - page 40

___Set header to rigid mode, ensure all tabs on ex sensing rod are in proper position. - page 49 and page 120

___Set reel nger pitch to a starting point of 5. - page 50

___Ensure reel ngers clear cutter bar by minimum of 1 1/2”. Adjust reel height if necessary. In order to fully extend the right hand reel

lift cylinder the header reel must be running - page 50

___Set Auto Header Height parameters in combine control panel (Combine and Sensitivity Settings) - page 41

___Calibrate header height control on Automatix control panel - page 39

___Calibrate combine (In FLEX and RIGID mode)

___Run header and ne tune drive belt to minimize vibration and get it running smoothly.

___Walk around the header while it is running to ensure everything is running smoothly

___If possible test in the eld or lot and ne tune sensitivity settings if needed

___Red draw bar holder and tie-down bracket removed from header. - page 32

___Ensure Optional equipment as per sales order is installed and functioning.

Revision: 1.7 03/12/2018

Honey Bee Manufacturing Ltd.

AirFLEX Delivery Inspection Report

AirFLEX Pre Delivery Inspection

TO THE DEALER: This form must be completed and returned to Honey Bee Manufacturing Ltd. along with the Warranty Registration Form.

(please print)

Model: Serial #:

Check Completed By: Signature:

Dealer Name: Date:

(White - Return to Honey Bee) (Yellow - Dealer Copy) (Pink - Customer Copy)

Upon Receipt of Header:

As soon as you receive this machine, inspect it thoroughly to be certain that it is in good order and complete. Finish a pre-delivery

inspection, paying special attention to the steps listed below, prior to delivery to the customer. Indicate with a tick mark in the left-hand

column when correct/complete.

Refer to the page numbers listed below in the operator manual for detailed instructions.

Before Transporting:

___Tilt cylinder retracted. - page 49

___Drive shafts in storage position. - page 88

___Header in rigid mode (air system pressurized to 100 psi). - page 49

___Hydraulic & electrical connectors/lines in storage positions.

___Reel lowered, retracted, tied down and prevented from rotating.

___Transport cart & front draw bar axle properly installed. - page 85

___Automatix display and electrical harness, dividers, extensions & accessories securely stored.

___Warning lights, decals, reectors & signs all legible and in place. - page 20

___Front reel ngers dropped into transport position. - page 86