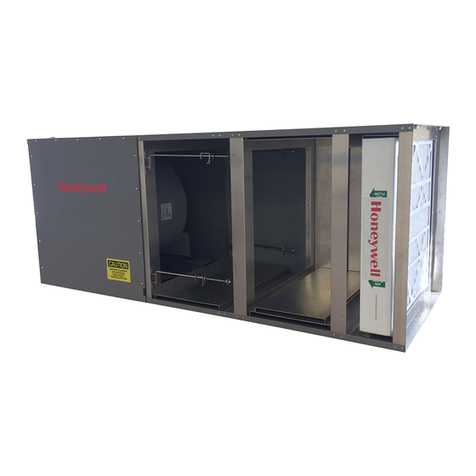

F111 (SERIES 3) IN CEILING MEDIA AIR CLEANER

68-0198—05 8

The CPZ™ sorbent module has the ability to collect and

hold gas-phase compounds and vapors typically found in

commercial and light industrial facilities. These gases and

vapors frequently appear as odors that, at times, can be

annoying and irritating. The modules become saturated

after collecting 25% to 50% of their weight in gaseous

odors. The quantity of CPZ™ material provides adequate

dwell time to ensure up to 95% collection efficiency in the

first pass. This also provides a long maintenance-free

service life.

The minimum recommended air exchange rate is 2.5 times

per hour. In a heavily contaminated area, up to 15 air

exchanges per hour can be necessary. The factors that

determine what the rate of air exchange should be are:

• Generation rates of the various pollutants;

• Concentration level of the pollutants;

• Desired contamination reduction level.

Airborne contaminants will always be present in the air

where contaminant generations take place. Air cleaning

systems and ventilators do not eliminate airborne

contaminants, they reduce the excessive accumulation of

the contaminants. To eliminate the contamination, the

source of contamination must be removed.

Local, Federal and professional ventilation engineering

standards and codes prescribe minimum ventilation rates

to dilute air contamination in specific applications. The

ventilation rates usually assume the injection of outdoor

air measured as air exchange rate. The use of the F111

(Series 3) air cleaner to comply with ventilation

requirements is an acceptable alternative to ventilation

with outdoor air. However, at least 20% of a specified

ventilation rate or code must be derived from outdoor air.

The F111 (Series 3) air cleaner filtered and recirculated air

can be the remaining 80%.

SERVICE

Electrical Hazard.

Can cause personal injury or equipment damage.

Turn off power before installing or servicing the air

cleaner.

IMPORTANT

Be sure to change filters as recommended to pre-

vent reduced airflow in the air cleaner.Stand on a

stable platform when working with the air cleaner.

The useful life of the CPZ™ sorbent modules may vary from

4 to 24 months, depending on the application. In most

applications, the sorbent media life ranges from 12 to 18

months. The particle filter life ranges from 6 to 24 months

with 12 to 24 months as an average. The modules and

filters need to be changed more frequently in facilities that

operate 24 hours a day.

Prefilter

The disposable prefilter collects large dust particulates

and lint- type airborne fibers. Check the filter every two

weeks to determine the replacement frequency:

1. Slowly open the lid, supporting the lid so the filters do

not fall out.

2. Remove the dirty prefilter.

3. Install the new prefilter in the air cleaner lid. Position

the prefilter so that the Air Flow Direction Arrow is

facing upward when the lid is closed.

4. Close and latch the lid.

Particle Filter

The particle filter collects particulates that pass through

the prefilter. The filter life is typically from 1 to 2 years.

There is decreased air quality and a pulsing sound when

the filter is filled with contaminants. The filter must be

replaced when the pulsing sound is noticed.

NOTE: The filter must be replaced. Washing, vacuuming

or reverse air blasting does not clean it.

1. Slowly open lid, supporting it so the filters do not fall

out.

2. Open the securing strips and with both hands. Slide

the filter toward you.

3. Place spent filter in a plastic trash bag and dispose of

properly.

4. Inspect the motor brackets for loose fasteners and

tighten as necessary.

5. Install the new filter noting the direction of airflow

arrow.

6. Lock and secure the particle filter into place by clos-

ing both latches.

IMPORTANT

Do not touch the pleated filter media. Handle only

the filter frame to prevent damage to the filter

media.

7. Close and latch the lid.

CPZ™ Adsorbent Module

The CPZ™ adsorbent module is used to collect gases,

vapors, odors and volatile organic compounds (V.O.C.) from

the air that passes through the air cleaner. Adsorbents

collect and hold 25% to 50% of their weight in odorous

gases and vapors. The impurities are collected until the

adsorbents reach saturation. At saturation, the adsorbents

emit a continuous strong pungent odor. If the air cleaner is

turned off for 8 to 10 hours, there will a temporary odor

when it is turned back on. If the odor persists for 30

minutes, it is time to replace the filters.

NOTE: When tobacco smoke is a contaminant, both the

particle filter and the adsorbent filter will need to

be serviced at the same time.

1. Slowly open the lid, supporting the lid so the filters do

not fall out.

2. Support the adsorbent module with one hand and

turn open the catches.

3. Use two hands and slide the filter from the housing.

IMPORTANT

The module weighs about 26 lb (12 kg) and can be

hard to handle.

4. Place the spent module in a plastic trash bag and

dispose of properly.

5. Remove CPZ™ sorbent modules from their packaging

and install.