บริษัท เอดีดี เฟอร์เนส จํากัด

ADD FURNACE CO.,LTD.

44 ซอยบรมราชชนนี 70 ถนนบรมราชชนนี แขวงศาลาธรรมสพน์ เขตทวีวัฒนา กรุงเทพฯ 10170

โทร: 02-888-3472 โทร: ออกแบบ:08-08-170-170 แฟกซ์: 02-888-3258

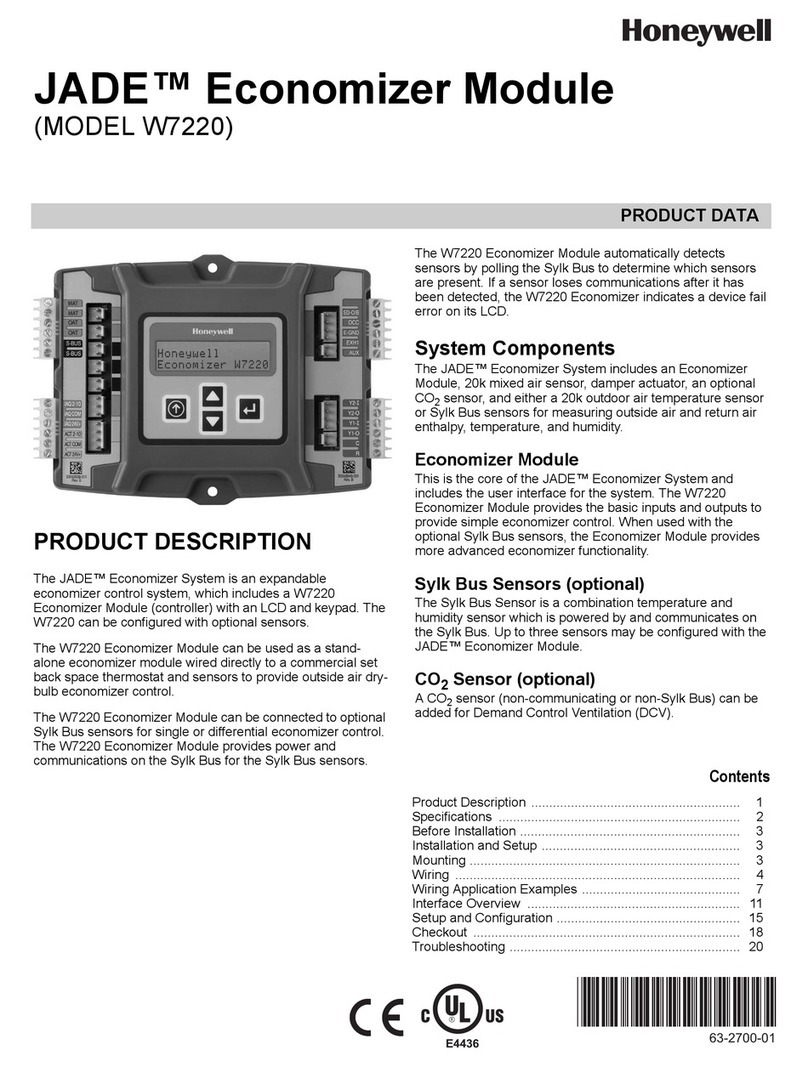

SPECIFICATIONS • INSTALLATION

4. For gases with specific gravities other than 0.64,

multiply the burner cfh by the proper conversion factor:

5. Use the corrected capacity in cf/h when determining

the gas valve size in Fig.1.

6. Determine the maximum pressure drop across the

valve and draw a horizontal line at this pressure inFig. 1.

7. Draw a vertical line in Fig. 1 at the capacity (cf/h)

previouslydetermined.Use the corrected capacityfora gas

with a specific gravity other than0.64.

8. Use the valve sizeat the intersectionof the horizontal

and vertical lines. If the intersection is between valve sizes,

use the next higher size to the right.

TO SIZE TWO IDENTICAL VALVES PIPED IN

SERIES

1. Find the cf/h for the type of gas used.

2. Consider both valves as one unit. Determine the total

maximum pressure drop across the unit.

3. Findthepressuredropacrossthefirstvalvebyassum-

ing it to be 45 percent of the total pressure drop.

4. Find the valve size from Fig.1.

5. The second valve will be the same size as the first

valve.

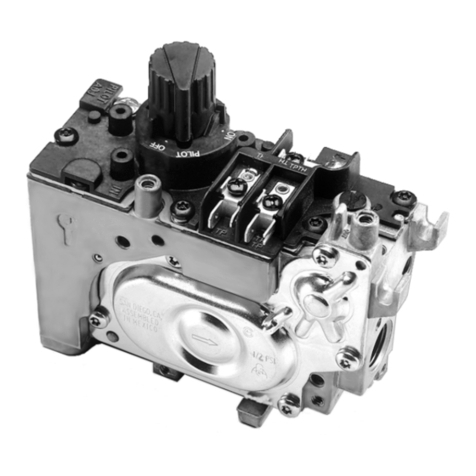

Installation

IMPORTANT: The V5055 Valve is designed to provide

control of gaseous fuel (natural and LP gas) flow in

applications in which there is minimal exposure to

water.V5055Valvesusedinmaritime,beverage,food

processing, outdoor and other installations in which

occasional exposure to water is experienced may be

subject to valve stem and spring corrosion. The pres-

ence of corrosion decreases the operating life of the

valve. V5055 Valves used in such installations should

be inspected at least annually and should have the

valve bonnets replaced if corrosion isnoted.

A V4055ValveActuator with a NEMA4 rating isalso

recommended for such installations. The water-tight

designof the NEMA 4 rated V4055 Actuator prevents

water from entering the V4055 valve stem and spring

chamber through the actuator. Under certain condi-

tions, some water may be retained by the external

upperportionof the valve body. The retained wateris

effectively excluded from the valve stem and spring

chamberby afunctionalsealthatisincorporatedinto

the NEMA 4 ratedactuator.

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced, flame safe-

guard control technician.

4. After installation is complete, check out product

operations as provided in these instructions.

CAUTION

1. Turnoff gas supplybefore starting installation.

2. Disconnect power supply for valve actuator

before beginning installation to prevent electri-

cal shock and equipmentdamage.

3. Besurethevalveisinstalledsothearrowonthe

valve points in the direction of gas flow. (Gas

pressure helps to close thevalve.)

LOCATION

Installthevalveinthegassupplylinedownstreamfrom

the pressure regulator. The valve and actuator may be

mountedinanypositionthatallowssufficientclearancefor

installation and for repair or replacement.

1. The valve position indicators should beeasily visible

with the valve and actuator in the final position.

2. Thefinalpositionofthevalveandactuatormustallow

for damper linkage, ifused.

IMPORTANT: Allow room for turning the valve body

(actuator not attached) onto the gas piping. Swing

dimensions,measuredfromthecenterofthepipeare:

3/4 through 1-1/2 in. valves: 4 in. (101.6 mm).

2 through 3 in. valves: 5 in. (127.0 mm).

4 in. valves: 7 in. (177.8 mm).

MOUNTING (Figs. 4 through 6)

WARNING

If flow is not in the direction of the arrow on the

valve body, the valve may not shut off.