Honeywell H808C User manual

Other Honeywell Controllers manuals

Honeywell

Honeywell Aquastat L4006A User manual

Honeywell

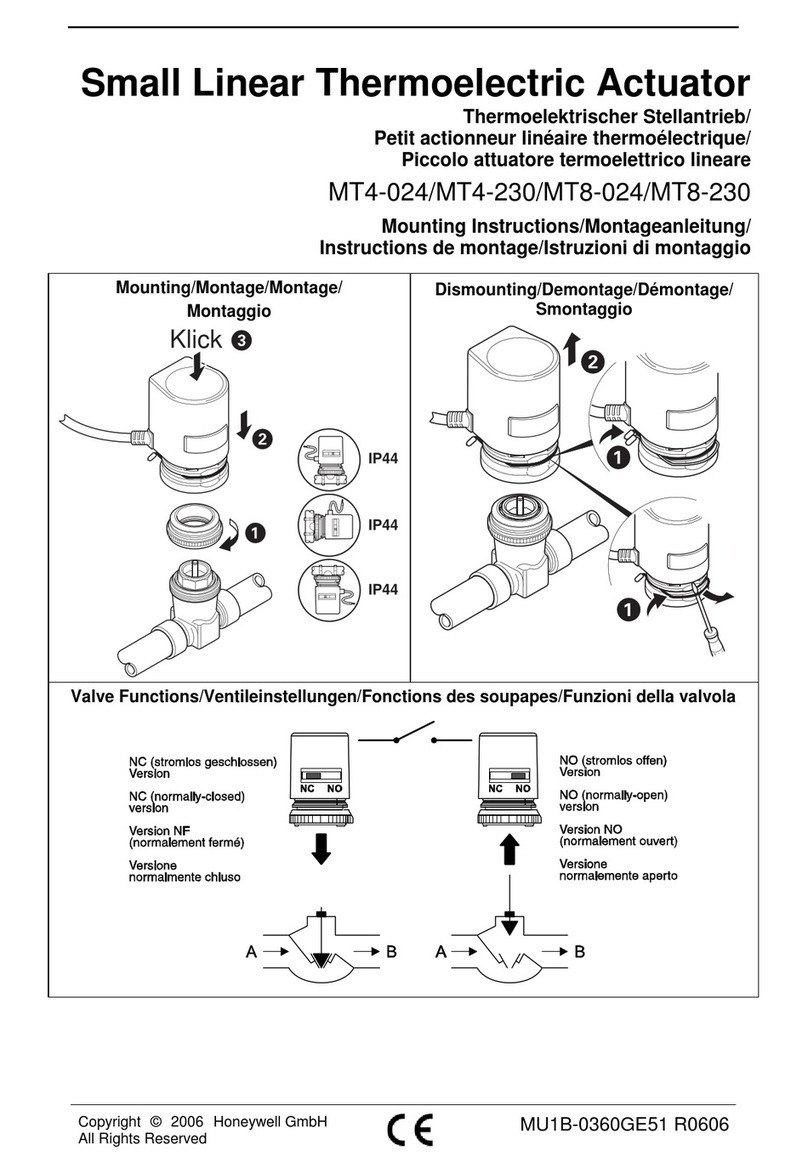

Honeywell MT4-024 User manual

Honeywell

Honeywell SDW 30 User manual

Honeywell

Honeywell Spyder PUB6438S User manual

Honeywell

Honeywell UDC120L User manual

Honeywell

Honeywell CP-UL1012S User manual

Honeywell

Honeywell 2RM7800L1087 Service manual

Honeywell

Honeywell Centraline LION Installation and operation manual

Honeywell

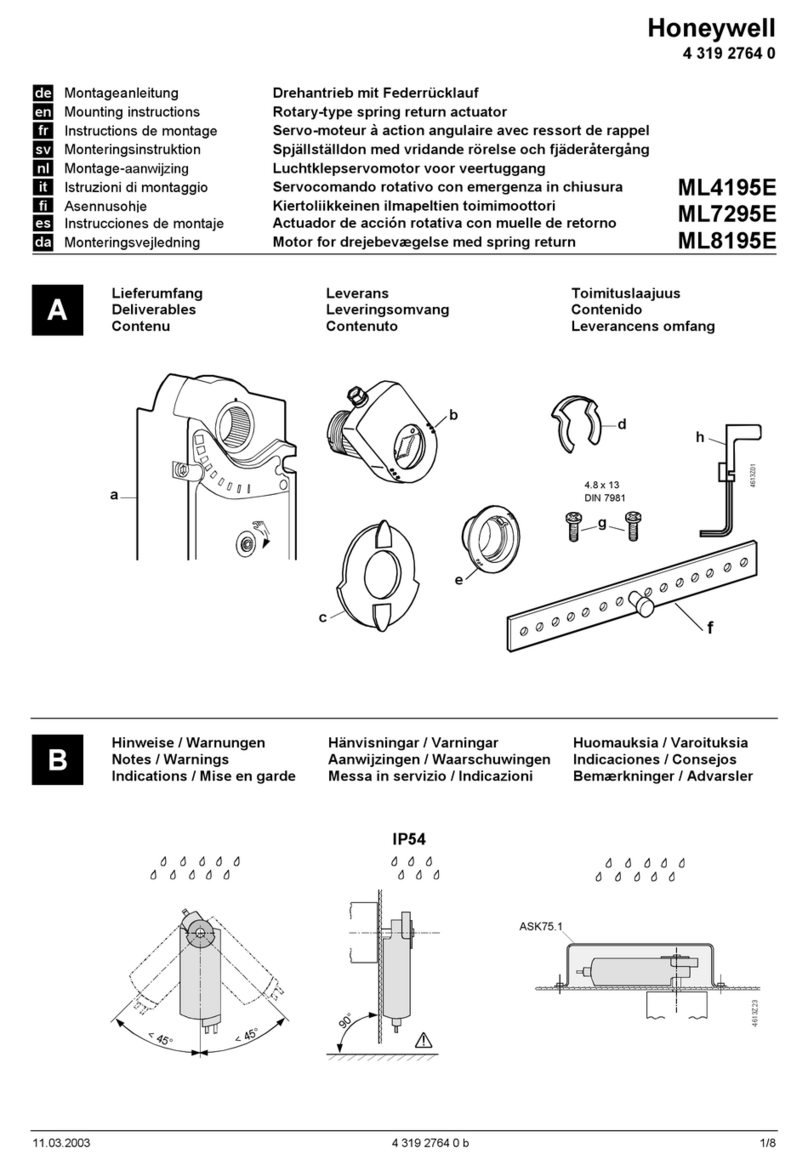

Honeywell ML4195E User manual

Honeywell

Honeywell SP907B User manual

Honeywell

Honeywell Lyric LCP500-LC Installation and operating manual

Honeywell

Honeywell S4965V3250 Operating and installation instructions

Honeywell

Honeywell HA71 User manual

Honeywell

Honeywell ESYS S4965A3025 Operating and installation instructions

Honeywell

Honeywell WEB-700 User manual

Honeywell

Honeywell UDC2500 User manual

Honeywell

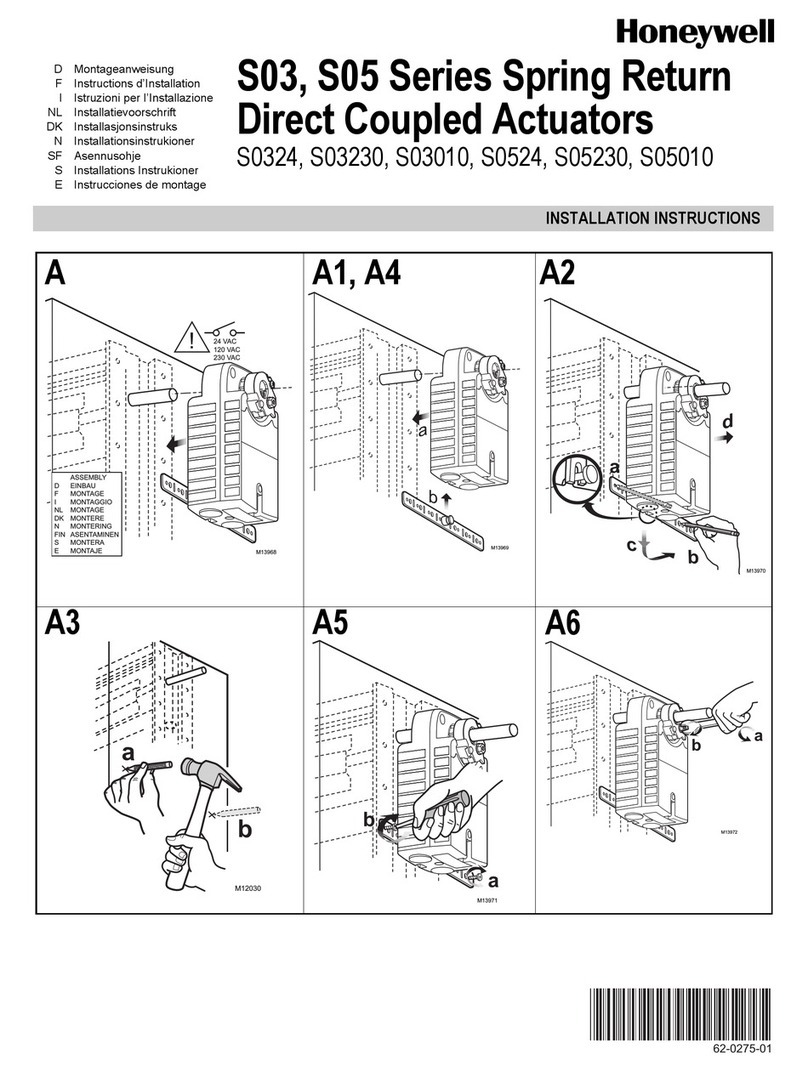

Honeywell S05 Series User manual

Honeywell

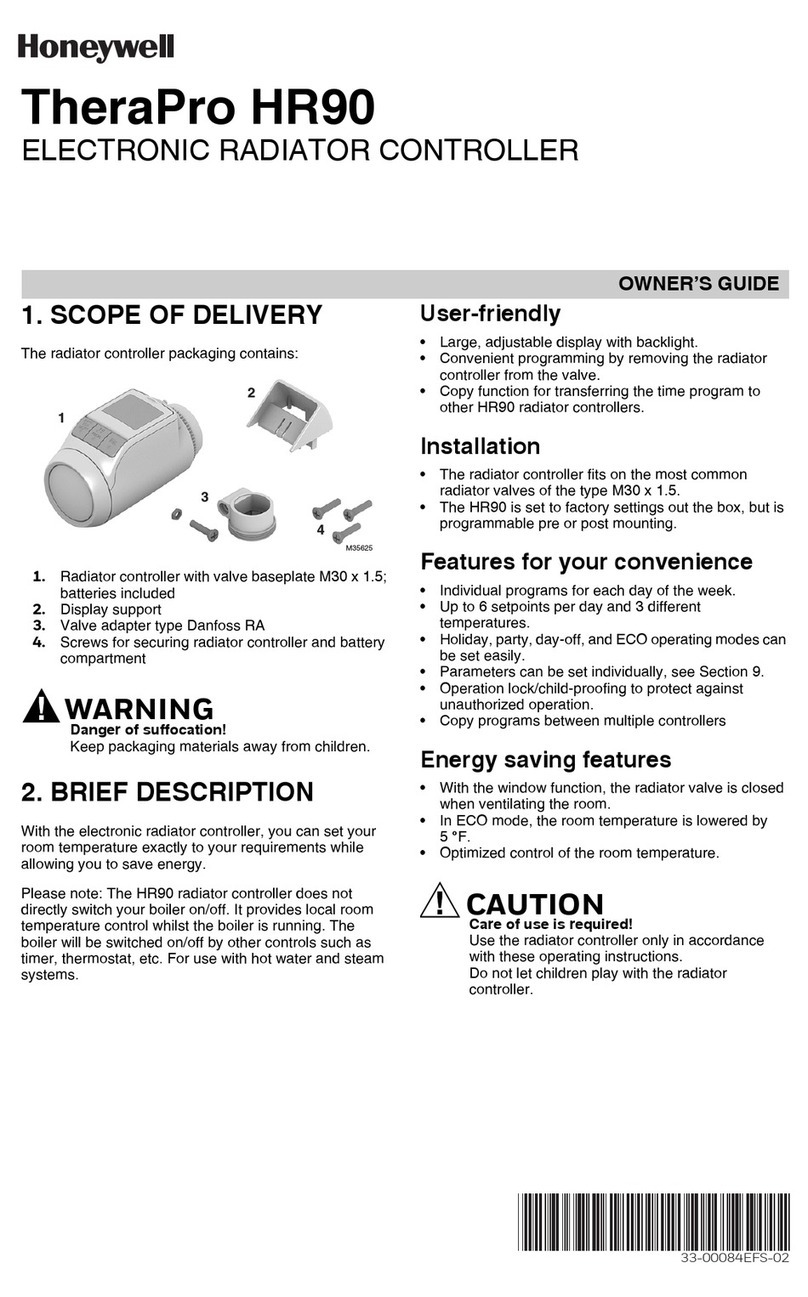

Honeywell TheraPro HR90 User manual

Honeywell

Honeywell H46C User manual

Honeywell

Honeywell homexpert Rondostat COMFORT+ HR30 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions