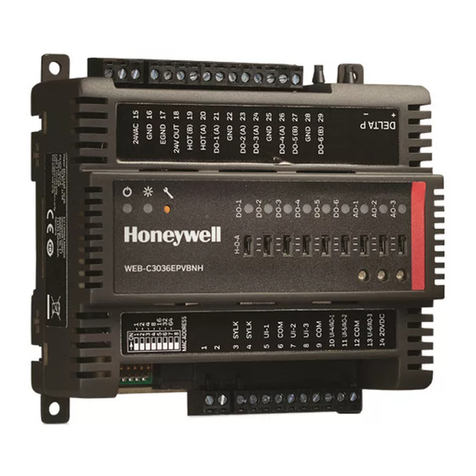

Honeywell W7752D2007 User manual

Other Honeywell Controllers manuals

Honeywell

Honeywell N20 Series User manual

Honeywell

Honeywell ML6161 Series Operation manual

Honeywell

Honeywell TUXWIFIS User manual

Honeywell

Honeywell DCP552 Mark II User manual

Honeywell

Honeywell Aquastat L7224U User manual

Honeywell

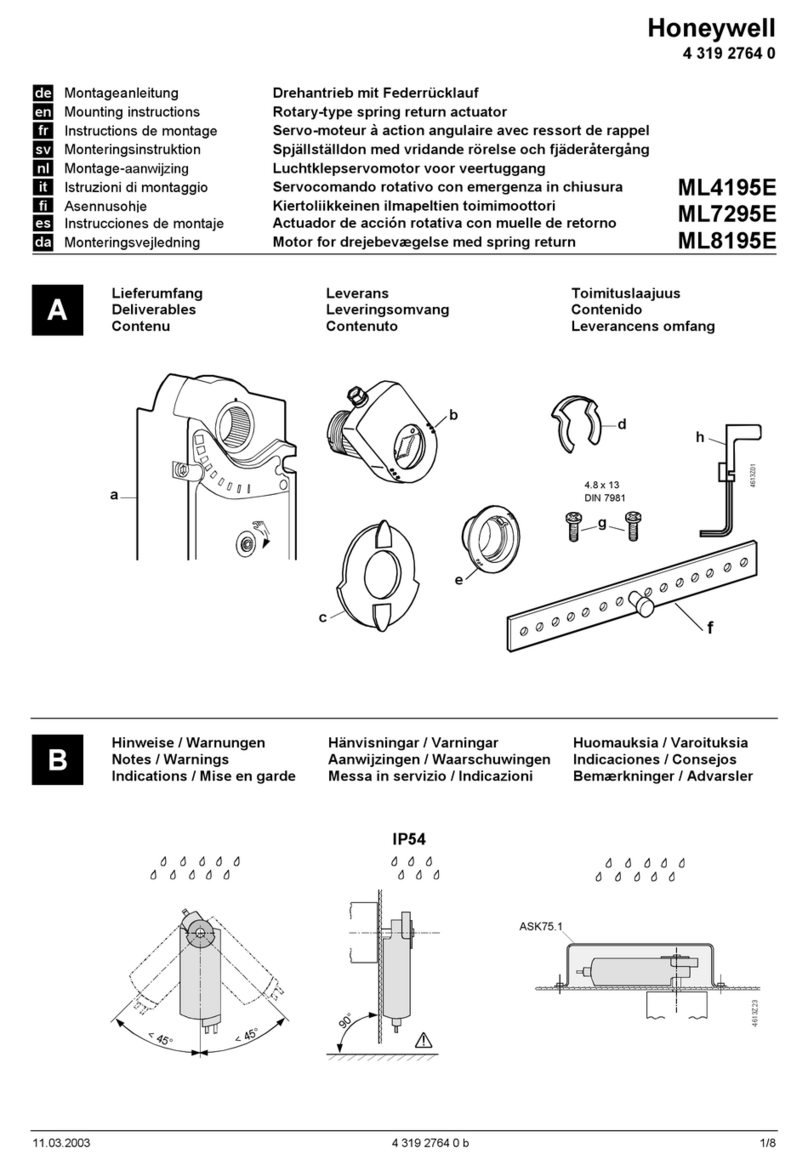

Honeywell ML4195E User manual

Honeywell

Honeywell CENTRA LINE MERLIN N Series User manual

Honeywell

Honeywell AQUASTAT L4188A User manual

Honeywell

Honeywell ControlEdge 900R04-0200 User manual

Honeywell

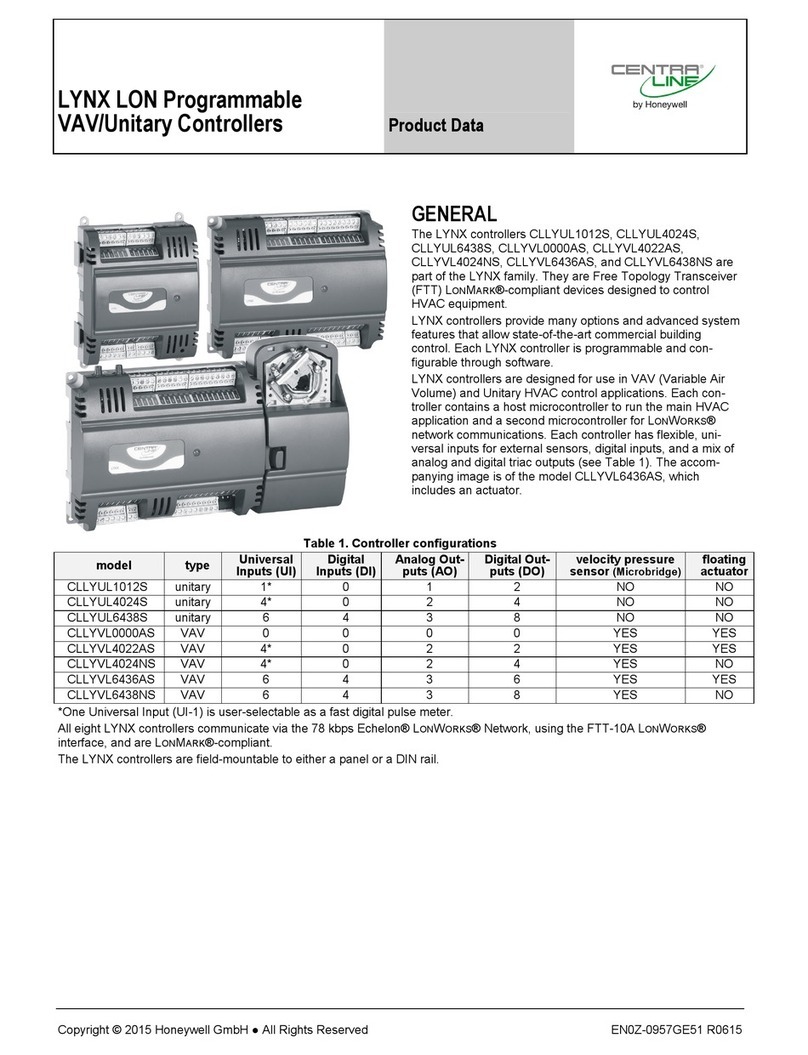

Honeywell CentraLine LYNX LON CLLYUL1012S Operation manual

Honeywell

Honeywell Enraf User manual

Honeywell

Honeywell SDW 30 User manual

Honeywell

Honeywell TheraPro HR90 User manual

Honeywell

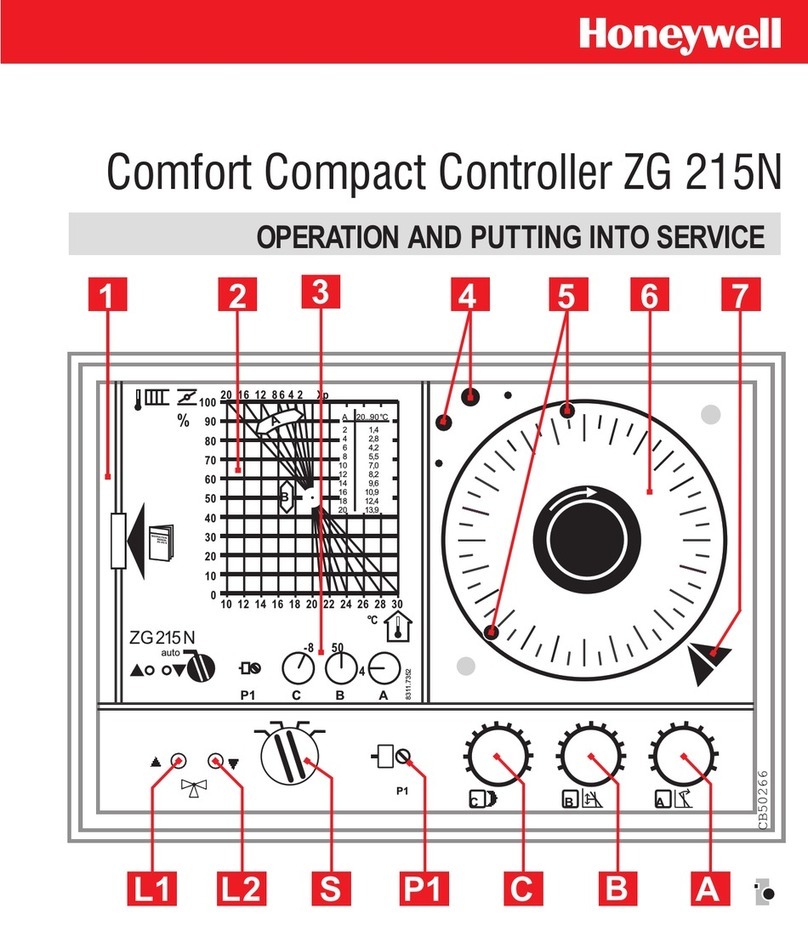

Honeywell ZG 215N User manual

Honeywell

Honeywell CIPer 30 User manual

Honeywell

Honeywell HA71 User manual

Honeywell

Honeywell Lyric Operating instructions

Honeywell

Honeywell HUPF Series User manual

Honeywell

Honeywell HON R100NG Series Operating instructions

Honeywell

Honeywell Temaline TS2 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions