4EN1R--9102 9402R1--NE

INSTALLATION AND CHECKOUT

Important

:

Before connecting the controller to

main supply, wait for at least one

hour.

:

Installer must be a trained

experienced service man.

:

Disconnect power supply to

prevent electrical shock and/or

equipment damage.

:

Before installing or replacing any

control check that type number is

correct for the application.

:

The appliance manufacturer’s

instructions should always be

followed when provided.

If such instructions are not

provided see fig. 3 and 4 for typical

systems.

:

Ensure combustion chamber is free

of gas before start up.

:

At the first start the automatic

ignition controller can be in lock

out; depress reset button to free

control.

:

Never open the upper part, which

includes the electronics

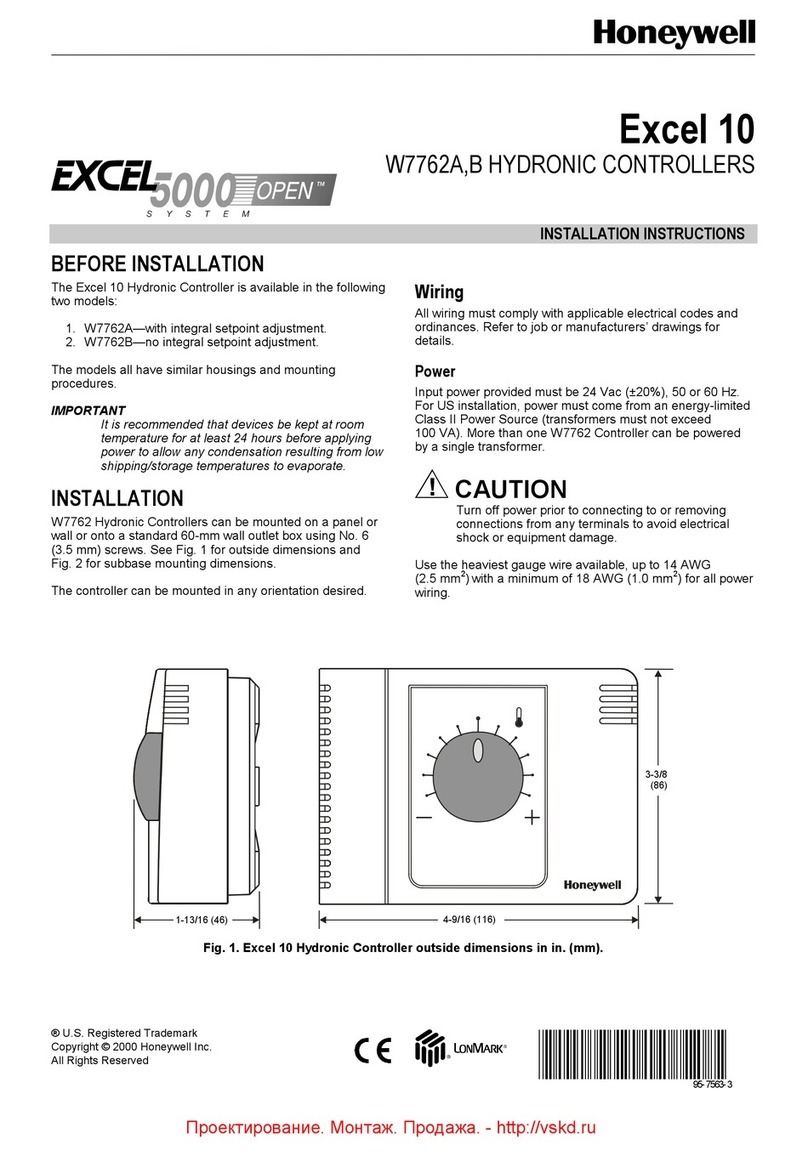

Mounting

The automatic ignition controller should

be mounted on a flat surface by means

of 2 screws in the mounting holes of the

subbase.

Mounting position

The automatic ignition controller

functions position independently and

such can be mounted in any position.

Spark gap

Refer to the appliance manufacturer’s

instructions for recommended ignition

electrode position.

Maximum allowable spark gap: 4 mm

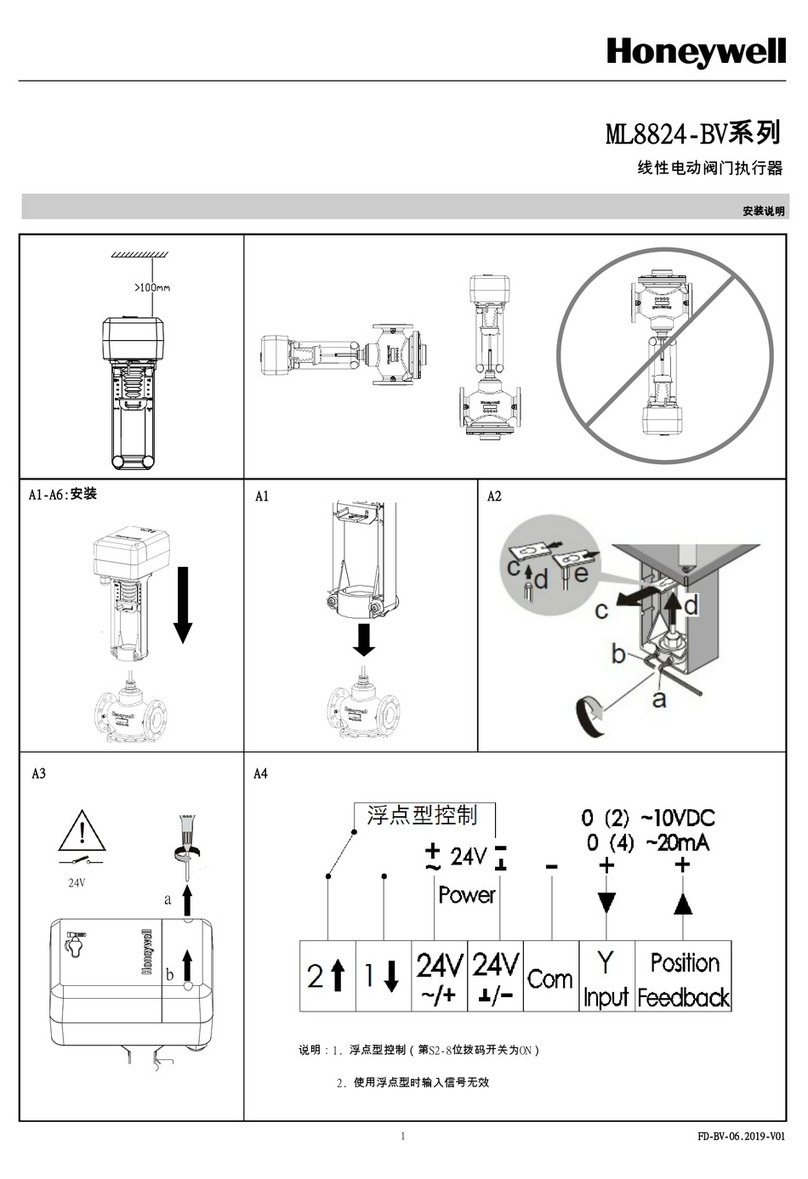

Wiring

:

Wiring must be in accordance with

local regulations

:

Use leadwire which can withstand

105

E

C ambient.

:

Use leadwire which is proven against

moisture.

:

Wiring between automatic ignition

controller and spark sensing probe

should have good quality insulation,

suitable for the temperatures encoun-

tered.

Supply voltage polarity

Warning

If automatic ignition controller seems

to operate normally but does not

detect ignition flame, check for right

polarity of power supply (line,

neutral).

Checking flame current

:

The minimum value should be 1 µA.

:

To check flame current connect a DC

micro--Ampèremeter between flame

sensing wire and flame sensing rod.

(see fig. 1 and 2).

:

If flame current is insufficient, check

that:

-- proportion of flame touching the

grounded portion of the burner

is3to4timestheproportion

enveloping the flame rod.

-- there is a good ground

connection to the controller.

Checkout

After installation, set burner system in

operation and observe through a

complete cycle to ensure that burner

system components function correctly.

See fig. 6 for sequence status LED’s

GENERAL CONSIDERATIONS

The automatic ignition controller should

be externally fused.

If, due to a short circuit, the internal

fuse is blown, the automatic ignition

controller must be repaired by

Honeywell.

When the automatic ignition controller

is built in an appliance, the total

protection must be IP40 at least.

To ensure reliable long term operation,

mount automatic ignition controller at a

positionintheappliancewithalow

ambient temperature and a low thermal

radiation.

High temperatures will affect product

life negatively.

For safety a high limit thermostat must

be connected in series with the

thermostat to de--energize the

automatic ignition controller in case of

overtemperature.

To suppress Radio Frequency

Interference (RFI) the automatic ignition

controller including spark igniter

cabling should be mounted in sufficient

shielded environment.

Note

Electrical rating of connected controls

should be appropriate for the load

that is switched by the automatic

ignition controller.