-7-

No.PF※※-OMA1018

●Product handling

Mounting

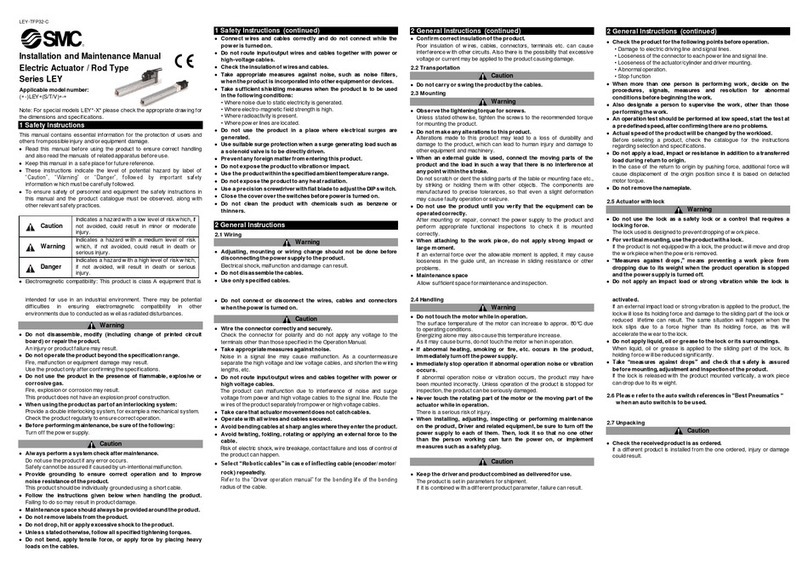

•Tighten screws to the specified tightening torque.

If the tightening torque is exceeded, the mounting screws, brackets, the product, and other parts may be damaged.

Insufficient torque can cause displacement of the product from its correct position and looseness of the screws.

(Refer to Mounting and Installation on page 16).

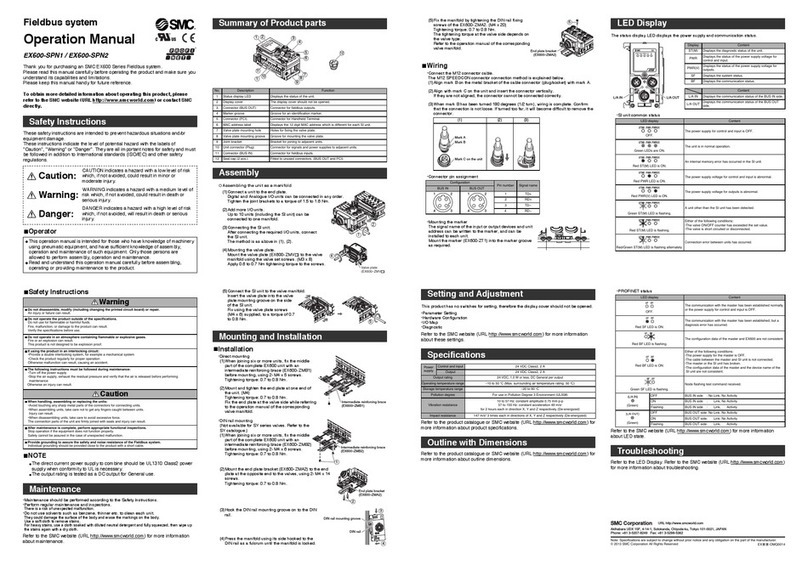

•If a commercially available switching power supply is used, be sure to ground the frame ground (FG)

terminal.

•Do not use where the product is subjected to vibration or impact.

Otherwise, it may damage the internal components and cause malfunction.

•Do not pull the lead wire forcefully or lift the product by the lead wire.

(Tensile strength 49 N or less)

Hold the product body when handling.

Otherwise, it may damage the product and may cause failure and malfunction.

•For piping of the flow controller, hold the piping with a spanner on the metal part of the product only

(metal piping attachment).

Holding other parts with a spanner may damage the product.

Specifically, make sure that the spanner does not damage the M12 connector.

This may damage the connector.

•Any dust left in the piping should be flushed out by air blow before connecting the piping to the product.

Otherwise, it can cause damage or malfunction.

•Refer to the fluid flow direction indicated on the product label during installation and piping.

Otherwise, it will be unable to measure accurately.

•Avoid sudden changes to the piping size on the IN side of the product.

If the piping size is reduced or there is a restrictor such as a valve, close to the product on the IN side, the fluid

velocity distribution in the piping will be disturbed, leading to improper measurement.

An inner diameter of 9 mm or more is recommended for the piping size of the product on the IN side.

•Do not insert metal wires or other foreign matter into the flow path.

The sensor may be damaged causing failure or malfunction.

•Never mount the product in a place that will be used as a mechanical support.

The product may be damaged if excessive force is applied by stepping or climbing onto it.

•If the fluid may contain foreign matter, install and connect a filter on the IN side.

Accurate measurement may not be obtained if foreign matter has adhered to the vortex generator or vortex

detection element of the flow rate sensor unit.

In addition, the adhesion of foreign matter to the valve parts may cause issues with the valve operation. Therefore,

the installation of a filter with 150 meshes (100 µm) or more is recommended.

•Design and install the product to keep the internal passage filled with fluid.

•Do not mount the product with the display facing downward.

•When mounting it vertically, the fluid must flow from the bottom to the top.

An accurate measurement may not be obtained when fluid flows from the top to the bottom due to bubbles of

entrained air.

(There should not be a problem as long as the fluid passage is completely filled with fluid).

•The product body is made of resin. Do not apply load directly to the body when piping.

Otherwise, it may damage and/or cause water leakage.