ML9185 SPRING RETURN DIRECT COUPLED ROTARY ACTUATOR

63-2494—1 4

Device Weight:

4.0 lb (1.82 kg).

Noise Rating (Driving Only):

45 dBA maximum at 1.0m.

Spring Rotation:

Clockwise (cw); counterclockwise (ccw) by reverse mounting.

Position Indicator:

Mounted on actuator hub.

Actuator Design Life:

Full Stroke Cycles: 60,000.

Repositions: 1,500,000.

Spring Return Cycles: 7,500.

Approvals:

UL94-5V (enclosure) plenum rating.

UL873 (line voltage auxiliary switches).

CSA: File Number E4436, Guide Number XAPX.

Environmental Protection Ratings:

NEMA1 standard with shaft in the horizontal position.

Mounting Tab:

For use with Universal mounting bracket.

Accessories:

205820A 3-Point Mounting Kit.

205830A Crank-Arm Accessory.

205753 Hub Sleeve, 3/8 in.

205758 Hub Sleeve, 5/8 in.

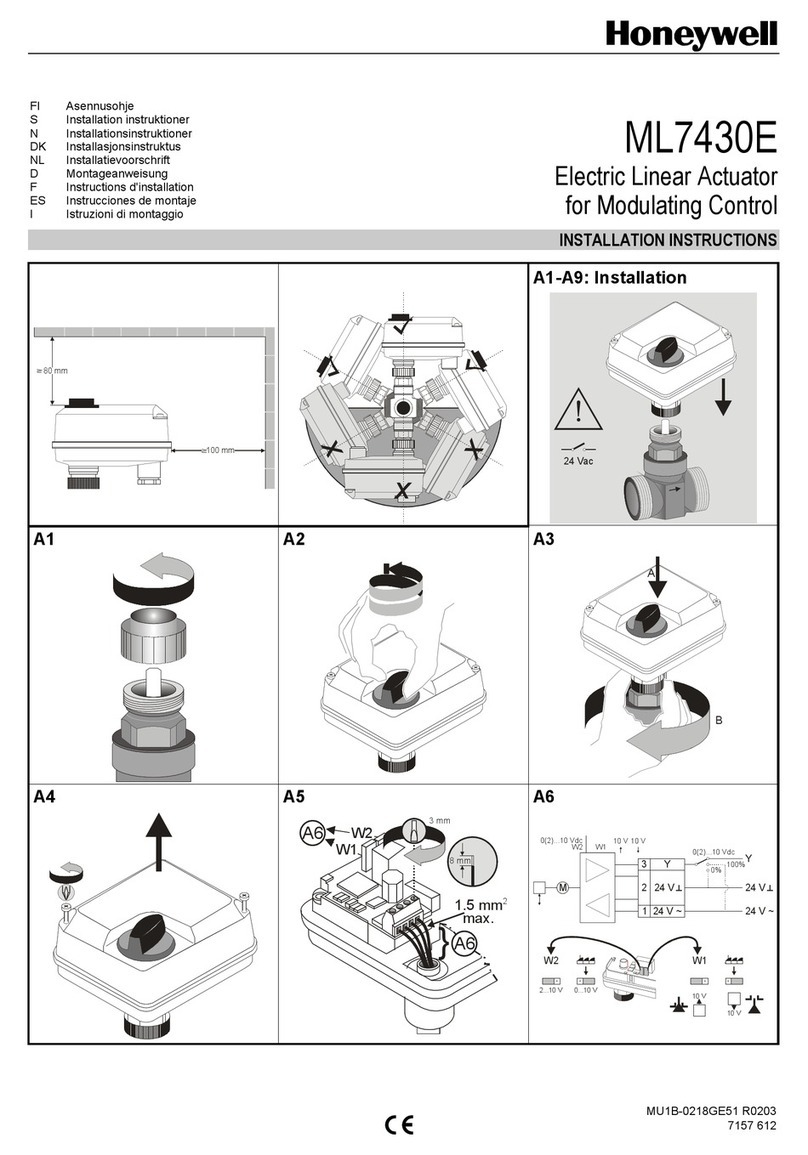

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings and description given in this

specification to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

1. Disconnect power before installation to prevent

electrical shock or equipment damage.

2. Never turn motor output hub by hand or with a

wrench.

3. Do not install actuator in areas with acid fumes or

other deteriorating vapors that might attack the

metal parts of the actuator.

4. Do not install actuator in areas with escaping gas

or other explosive vapors that could be ignited by

a spark from the actuator or attached

accessories.

Location

Install the actuator in any location free from acid fumes or

other deteriorating vapors that can attack the metal parts of

the actuator. Make sure the location is not subject to escaping

gas or other explosive vapors that could accidentally be

ignited by a spark from the actuator or its attached parts.

Install the actuator in a location that allows enough clearance

for mounting accessories and for servicing.

Mounting

The ML9185 Direct Coupled Actuator is designed to operate

a damper by driving the damper shaft either cw or ccw

depending on damper design. All actuators are shipped

in the fully closed position.

The ML9185 Direct Coupled Actuator is designed for single-

point mounting when using an adapter bracket. Single-point

mounting is typically used when the actuator is mounted on

the damper frame.

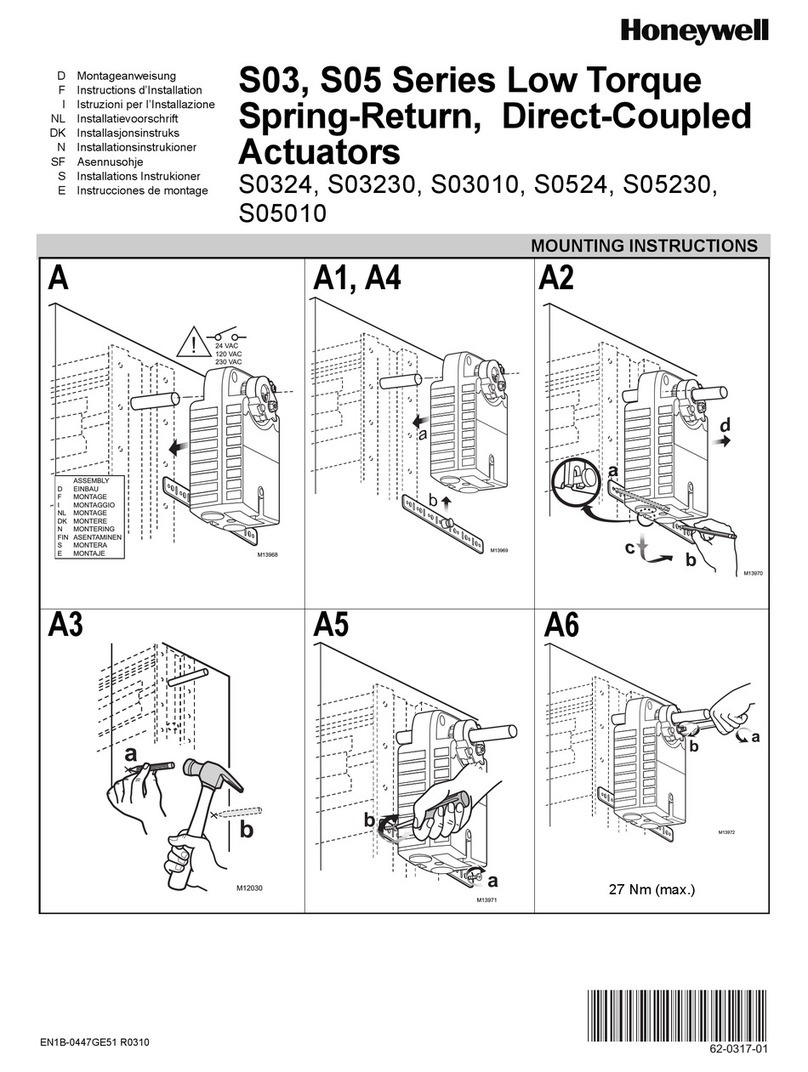

A mounting bracket (see Fig. 1) is provided with some models

to aid in installing the actuator. The bracket can be bent to

any shape to support the actuator at the correct height.

The ML9185 Direct Coupled Actuator can also be three-point

mounted using the two front gear housing slots and the

adapter bracket. Secure two screws through the two front

gear housing slots and position the adapter bracket to secure

the rear of the actuator. Three point mounting is used for foot

mounting the actuator or mounting the actuator internally in

the duct when direct shaft coupling is not possible.

CAUTION

Do not use the actuator as a shaft bearing. The

actuator must be used only to supply rotational

torque. To prevent damage to the actuator, avoid any

side loads to the actuator output coupling bearings.

Preparation

Before installing the ML9185 on the damper shaft, determine

the opening direction of the damper shaft to select the correct

spring return rotation and correctly connect the wiring. The

ML9185 can be mounted to provide clockwise or

counterclockwise spring return. Reverse the actuator, if

necessary, to provide the desired spring action.

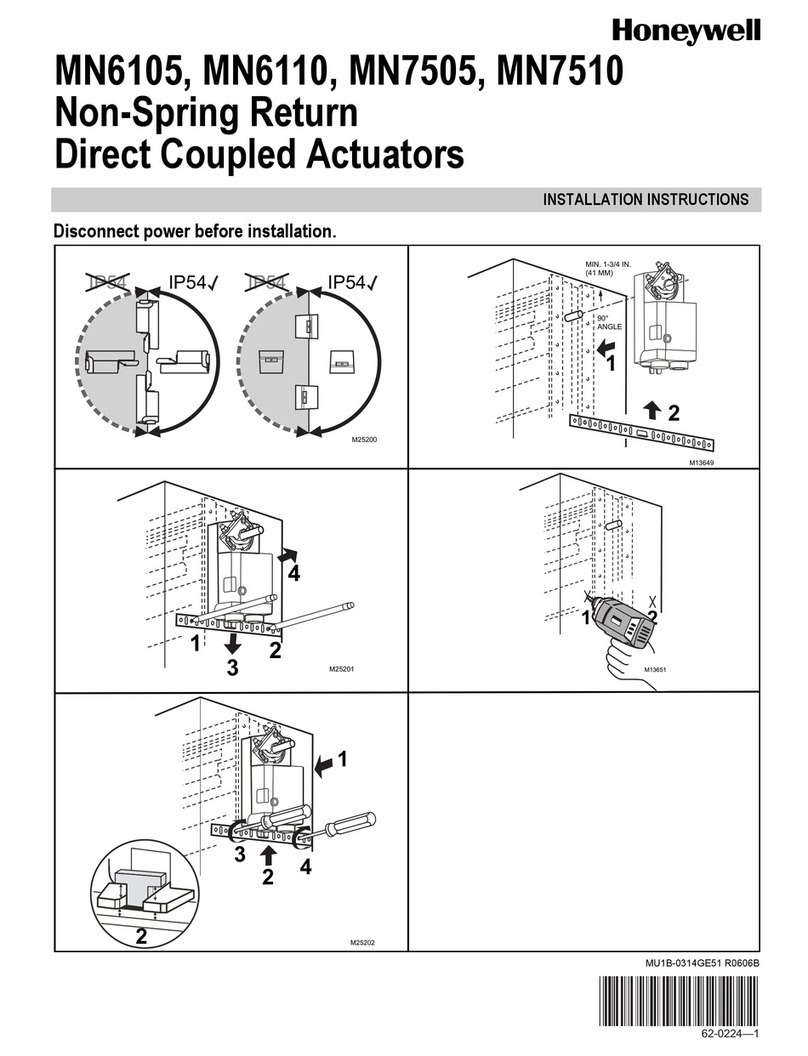

Installing Actuator and Mounting Bracket (Single

Point Mounting)

When the direction of the damper shaft rotation is determined

(either cw or ccw ), proceed as follows:

쐃Place the ML9185 Direct Coupled Actuator over the

damper shaft.

쐇Position the actuator for best access to the actuator

damper shaft locking screw.

쐋Install the mounting bracket (see Fig. 2) and adjust it to

support the actuator at the correct height. Mark the

screw holes for installing the mounting bracket on the

damper housing.