769-0624—2

LIGHT MAIN BURNER

Follow the appliance manufacturer instructions or set the

thermostat setting above room temperature to call for heat.

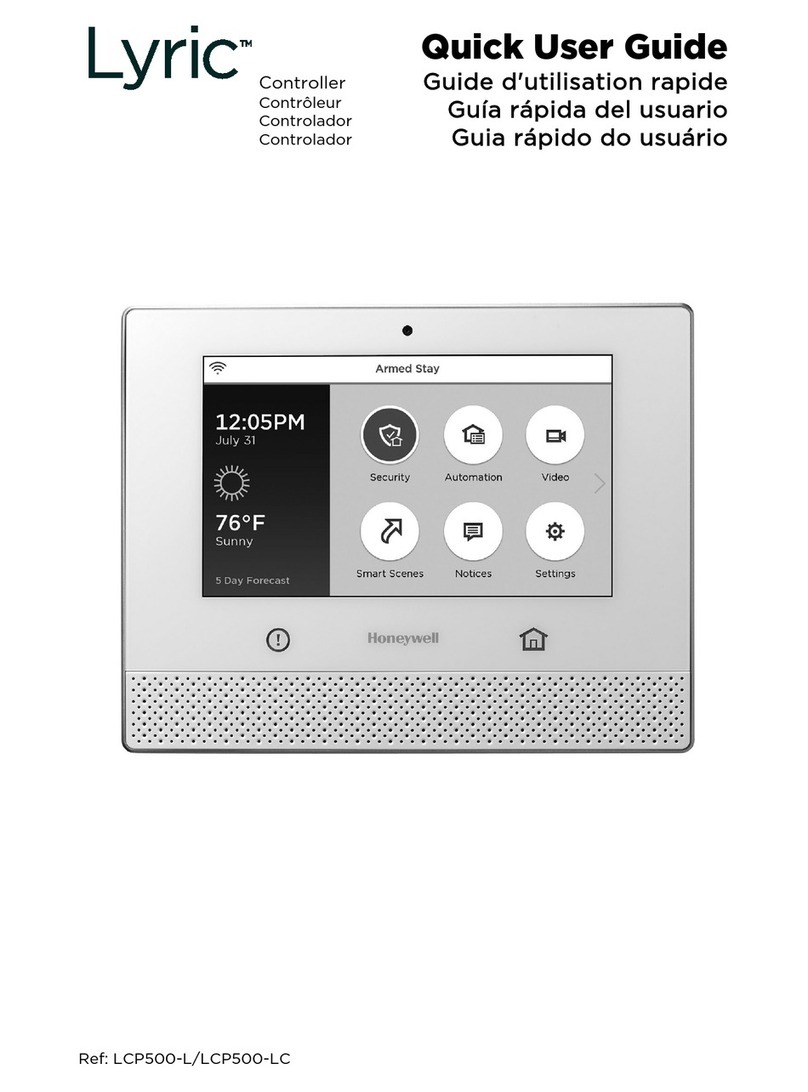

Fig. 10—Proper flame adjustment.

CHECK AND ADJUST GAS INPUT TO MAIN

BURNER

CAUTION

1. Do not exceed the input rating stamped on the

appliance nameplate, or the manufacturers rec-

ommended burner orifice pressure for the size

orifice(s) used. Make sure the main burner pri-

maryairsupplyisproperlyadjustedforcomplete

combustion (refer to the appliance manufactur-

ers instructions).

2. WHEN CHECKING GAS INPUT BY

CLOCKING THE GAS METER:

•Makesurethatthe only gas flow through the

meter is that of the appliance being checked.

•Make sure that other appliances are turned

offandthatthepilotburnersareextinguished

(or deduct the gas consumptions from the

meter reading).

•Converttheflow rate to Btuh as describedin

theGasControlsHandbook,(form70-2602),

and compare to the Btuh input rating on the

appliance nameplate.

3. WHEN CHECKING GAS INPUT WITH A

MANOMETER (PRESSURE GAUGE):

•Make sure the gas control knob is in the

PILOT position before removing the outlet

pressure tap plug to connect the manometer.

•Turn the gas control knob back to PILOT

when removing the manometer and replac-

ing the outlet pressure tap plug.

•Shut off the gas supply at the appliance

service valve or, for LP gas, at the gas tank

before removing the outlet pressure tap plug

andbeforedisconnectingthemanometerand

replacing the outlet pressure tap plug.

Standard-Opening and Slow-Opening Pressure

Regulator

1. Thegascontroloutletpressureshouldmatchthemani-

fold pressure listed on the appliance nameplate.

2. With the main burner operating, check the gas control

flow rate using the meter clocking method or check the gas

pressure using a manometer connected to the gas control

outlet pressure tap. Refer to Fig. 4.

3. Ifnecessary, adjust thepressureregulatortomatch the

appliance rating . Refer to Table 8 or 9 for the factory set

nominal outlet pressures and adjustment ranges.

a. Remove the pressure regulator adjustment cap screw.

b. Using a screwdriver, turn the inner adjustment screw

clockwise to increase or counterclockwise.

to decrease the main burner gas pressure.

c. Always replace the cap screw and tighten firmly to be

sure of proper operation.

4. If the desired outlet gas pressure or gas flow rate

cannot be achieved by adjusting the gas control, check the

gas control inlet pressure using a manometer at the inlet

pressuretap.Ifthe inlet pressure is in the normal range (refer

to Table 8 or 9), replace the gas control. Otherwise, take the

necessary steps to provide proper gas pressure to the gas

control.

Step-Opening Pressure Regulator

1. The gas control outlet pressure should match the

manifold pressure listed on the appliance nameplate.

2. With the main burner operating, check the gas control

flow rate using the meter clocking method or check the gas

pressure using a manometer connected to the gas control

outlet pressure tap. Refer to Fig. 4.

3. If necessary, adjust the pressure regulator to match

the appliance rating. Refer to Table 8 or 9 for factory set

nominal outlet pressures and adjustment ranges.

a. Remove the pressure regulator adjustment cap screw.

b. Using a screwdriver, turn the inner adjustment screw

clockwise to increase or counterclockwise

to decrease the main burner gas pressure.

c. Always replace the cap screw and tighten firmly to

safeguard proper operation.

4. 1f desired outlet pressure or flow rate cannot be

achieved by adjusting the gas control, check the inlet pres-

sure using a manometer at inlet pressure tap or upstream of

the gas control. If the inlet pressure is in the normal range

(refer to Table 8 or 9), replace the existing gas control.

Otherwise, take the necessary steps to provide proper gas

pressure to the gas control.

5. Carefully check main burner lightoff at the step pres-

sure. Be sure the main burner lights smoothly and without

flashbacktothe orificeandthat allportsremainlit.Cyclethe

main burner several times, allowing at least 30 seconds be-

tween cycles for the regulator to resume the step function.

Repeatafter allowing main burnertocool.Readjust the full

rate outlet pressure, if necessary, to improve lightoff

characteristics.

M3086A

PROPER FLAME

ADJUSTMENT 3/8 TO 1/2 INCH

[10 TO 13 MILLIMETERS]

THERMOCOUPLE