ELSTER RABO® Rotary Gas Meter 04 Honeywell

RABO® Rotary Gas Meter 03 Elster Instromet

4. Receiving, Handling and Storage

Elster RABO meters should be handled with care to protect the

product from damage. If the package shows evidence of damage

through mishandling in transit, you should notify the shipper

immediately, file a claim with the carrier and notify your Elster

supplier.

Damage to internal components may occur without visible

external damage. All new meters should be inspected and

checked for free rotation of the impellers by lightly blowing

into the inlet of the meter. This slight air pressure should

cause the impellers to rotate freely and come to a stop slowly.

NOTICE

DO NOT attempt to make any repairs. Tampering with the

meter may void warranty coverage.

If a meter shows signs of external damage, or if the impellers do

not rotate freely, contact your local Elster sales representative for

return instructions.

Elster RABO meters are supplied with oil in a separate container.

A material safety data sheet (MSDS) is available upon request. DO

NOT put oil in the meter until it is installed and leveled in the gas

piping system. Meters containing oil that are transported or not

installed level may lead to contamination of the measurement

chamber, and will impact accuracy.

Store Elster RABO meters in their original shipping container in a

dry location until installation. If prolonged storage is experienced,

RABO meters should be tested for accuracy before installation.

5. Installation

Elster RABO meters can be installed in horizontal or vertical (top

inlet) piping configurations. Vertical (top inlet) piping is preferred

because it enables the meter to pass contaminants more freely

through the meter. All piping should be properly supported

and aligned to eliminate any strain on the meter, which may cause

the impellers to bind.

Recommended piping practices include a filter or strainer on the

inlet of the meter and non-lubricated isolation valves. A bypass

line will facilitate maintenance and removal of the meter and

provide uninterrupted gas supply.

The meter should not be installed lower than the outlet pipe run.

If it is necessary to install the meter lower than the outlet pipe run,

installation of a drip leg in the outlet piping to capture condensate

is recommended. The meter should never be located at the lowest

point in the system.

A restricting orifice can also be installed at least 4 pipe diameters

downstream of the outlet of the meter to prevent the meter from

flowing excess capacity. Warranty does not cover failures due to

excess flow conditions.

Figure 2. Horizontal installation, side view

Figure 3. Vertical installation, side view

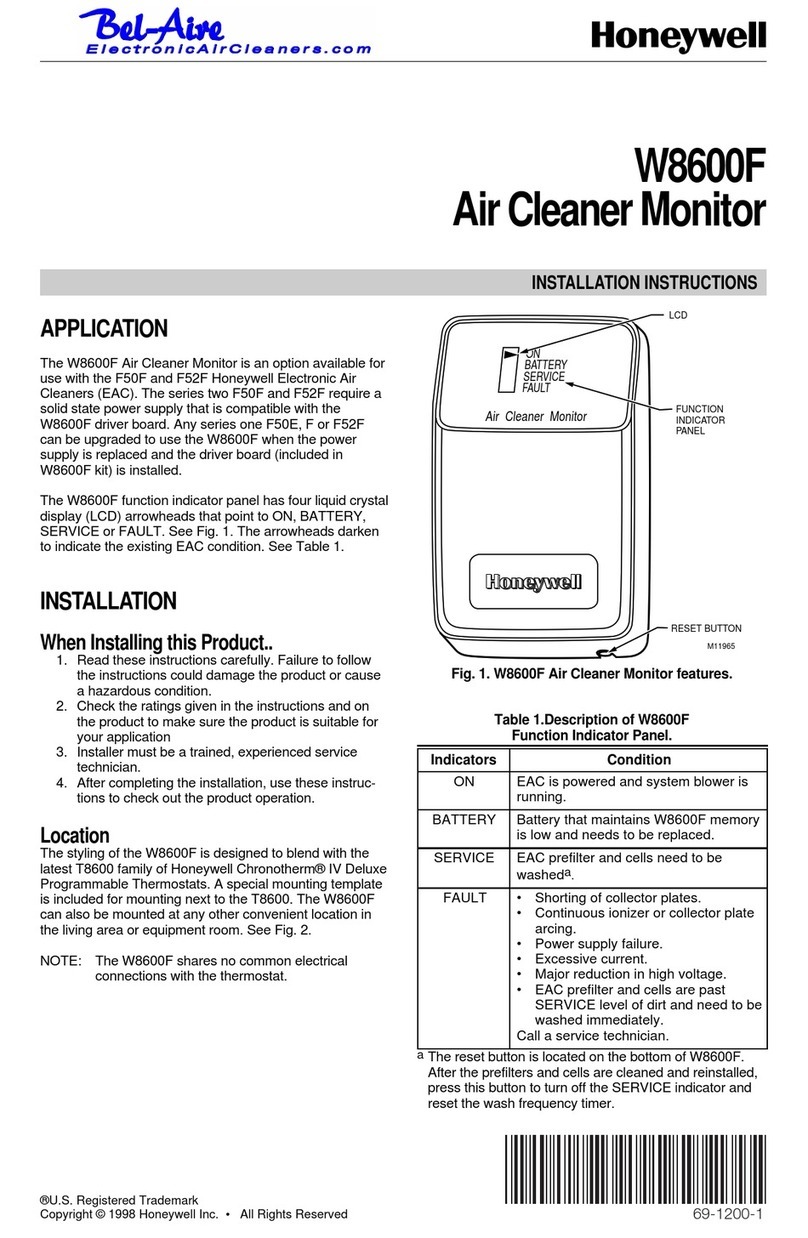

a) Piping Configurations [Figures 2, 3 and 4]

DO NOT weld piping while meter is installed in the

piping system.

If hydro testing, remove the meter from the piping system.

NOTICE

NOTICE

RABO® Rotary Gas Meter 03 Elster Instromet

4. Receiving, Handling and Storage

Elster RABO meters should be handled with care to protect the

product from damage. If the package shows evidence of damage

through mishandling in transit, you should notify the shipper

immediately, file a claim with the carrier and notify your Elster

supplier.

Damage to internal components may occur without visible

external damage. All new meters should be inspected and

checked for free rotation of the impellers by lightly blowing

into the inlet of the meter. This slight air pressure should

cause the impellers to rotate freely and come to a stop slowly.

NOTICE

DO NOT attempt to make any repairs. Tampering with the

meter may void warranty coverage.

If a meter shows signs of external damage, or if the impellers do

not rotate freely, contact your local Elster sales representative for

return instructions.

Elster RABO meters are supplied with oil in a separate container.

A material safety data sheet (MSDS) is available upon request. DO

NOT put oil in the meter until it is installed and leveled in the gas

piping system. Meters containing oil that are transported or not

installed level may lead to contamination of the measurement

chamber, and will impact accuracy.

Store Elster RABO meters in their original shipping container in a

dry location until installation. If prolonged storage is experienced,

RABO meters should be tested for accuracy before installation.

5. Installation

Elster RABO meters can be installed in horizontal or vertical (top

inlet) piping configurations. Vertical (top inlet) piping is preferred

because it enables the meter to pass contaminants more freely

through the meter. All piping should be properly supported

and aligned to eliminate any strain on the meter, which may cause

the impellers to bind.

Recommended piping practices include a filter or strainer on the

inlet of the meter and non-lubricated isolation valves. A bypass

line will facilitate maintenance and removal of the meter and

provide uninterrupted gas supply.

The meter should not be installed lower than the outlet pipe run.

If it is necessary to install the meter lower than the outlet pipe run,

installation of a drip leg in the outlet piping to capture condensate

is recommended. The meter should never be located at the lowest

point in the system.

A restricting orifice can also be installed at least 4 pipe diameters

downstream of the outlet of the meter to prevent the meter from

flowing excess capacity. Warranty does not cover failures due to

excess flow conditions.

Figure 2. Horizontal installation, side view

Figure 3. Vertical installation, side view

a) Piping Configurations [Figures 2, 3 and 4]

DO NOT weld piping while meter is installed in the

piping system.

If hydro testing, remove the meter from the piping system.

NOTICE

NOTICE

RABO® Rotary Gas Meter 03 Elster Instromet

4. Receiving, Handling and Storage

Elster RABO meters should be handled with care to protect the

product from damage. If the package shows evidence of damage

through mishandling in transit, you should notify the shipper

immediately, file a claim with the carrier and notify your Elster

supplier.

Damage to internal components may occur without visible

external damage. All new meters should be inspected and

checked for free rotation of the impellers by lightly blowing

into the inlet of the meter. This slight air pressure should

cause the impellers to rotate freely and come to a stop slowly.

NOTICE

DO NOT attempt to make any repairs. Tampering with the

meter may void warranty coverage.

If a meter shows signs of external damage, or if the impellers do

not rotate freely, contact your local Elster sales representative for

return instructions.

Elster RABO meters are supplied with oil in a separate container.

A material safety data sheet (MSDS) is available upon request. DO

NOT put oil in the meter until it is installed and leveled in the gas

piping system. Meters containing oil that are transported or not

installed level may lead to contamination of the measurement

chamber, and will impact accuracy.

Store Elster RABO meters in their original shipping container in a

dry location until installation. If prolonged storage is experienced,

RABO meters should be tested for accuracy before installation.

5. Installation

Elster RABO meters can be installed in horizontal or vertical (top

inlet) piping configurations. Vertical (top inlet) piping is preferred

because it enables the meter to pass contaminants more freely

through the meter. All piping should be properly supported

and aligned to eliminate any strain on the meter, which may cause

the impellers to bind.

Recommended piping practices include a filter or strainer on the

inlet of the meter and non-lubricated isolation valves. A bypass

line will facilitate maintenance and removal of the meter and

provide uninterrupted gas supply.

The meter should not be installed lower than the outlet pipe run.

If it is necessary to install the meter lower than the outlet pipe run,

installation of a drip leg in the outlet piping to capture condensate

is recommended. The meter should never be located at the lowest

point in the system.

A restricting orifice can also be installed at least 4 pipe diameters

downstream of the outlet of the meter to prevent the meter from

flowing excess capacity. Warranty does not cover failures due to

excess flow conditions.

Figure 2. Horizontal installation, side view

Figure 3. Vertical installation, side view

a) Piping Configurations [Figures 2, 3 and 4]

DO NOT weld piping while meter is installed in the

piping system.

If hydro testing, remove the meter from the piping system.

NOTICE

NOTICE

RABO® Rotary Gas Meter 03 Elster Instromet

4. Receiving, Handling and Storage

Elster RABO meters should be handled with care to protect the

product from damage. If the package shows evidence of damage

through mishandling in transit, you should notify the shipper

immediately, file a claim with the carrier and notify your Elster

supplier.

Damage to internal components may occur without visible

external damage. All new meters should be inspected and

checked for free rotation of the impellers by lightly blowing

into the inlet of the meter. This slight air pressure should

cause the impellers to rotate freely and come to a stop slowly.

NOTICE

DO NOT attempt to make any repairs. Tampering with the

meter may void warranty coverage.

If a meter shows signs of external damage, or if the impellers do

not rotate freely, contact your local Elster sales representative for

return instructions.

Elster RABO meters are supplied with oil in a separate container.

A material safety data sheet (MSDS) is available upon request. DO

NOT put oil in the meter until it is installed and leveled in the gas

piping system. Meters containing oil that are transported or not

installed level may lead to contamination of the measurement

chamber, and will impact accuracy.

Store Elster RABO meters in their original shipping container in a

dry location until installation. If prolonged storage is experienced,

RABO meters should be tested for accuracy before installation.

5. Installation

Elster RABO meters can be installed in horizontal or vertical (top

inlet) piping configurations. Vertical (top inlet) piping is preferred

because it enables the meter to pass contaminants more freely

through the meter. All piping should be properly supported

and aligned to eliminate any strain on the meter, which may cause

the impellers to bind.

Recommended piping practices include a filter or strainer on the

inlet of the meter and non-lubricated isolation valves. A bypass

line will facilitate maintenance and removal of the meter and

provide uninterrupted gas supply.

The meter should not be installed lower than the outlet pipe run.

If it is necessary to install the meter lower than the outlet pipe run,

installation of a drip leg in the outlet piping to capture condensate

is recommended. The meter should never be located at the lowest

point in the system.

A restricting orifice can also be installed at least 4 pipe diameters

downstream of the outlet of the meter to prevent the meter from

flowing excess capacity. Warranty does not cover failures due to

excess flow conditions.

Figure 2. Horizontal installation, side view

Figure 3. Vertical installation, side view

a) Piping Configurations [Figures 2, 3 and 4]

DO NOT weld piping while meter is installed in the

piping system.

If hydro testing, remove the meter from the piping system.

NOTICE

NOTICE

RABO® Rotary Gas Meter 03 Elster Instromet

4. Receiving, Handling and Storage

Elster RABO meters should be handled with care to protect the

product from damage. If the package shows evidence of damage

through mishandling in transit, you should notify the shipper

immediately, file a claim with the carrier and notify your Elster

supplier.

Damage to internal components may occur without visible

external damage. All new meters should be inspected and

checked for free rotation of the impellers by lightly blowing

into the inlet of the meter. This slight air pressure should

cause the impellers to rotate freely and come to a stop slowly.

NOTICE

DO NOT attempt to make any repairs. Tampering with the

meter may void warranty coverage.

If a meter shows signs of external damage, or if the impellers do

not rotate freely, contact your local Elster sales representative for

return instructions.

Elster RABO meters are supplied with oil in a separate container.

A material safety data sheet (MSDS) is available upon request. DO

NOT put oil in the meter until it is installed and leveled in the gas

piping system. Meters containing oil that are transported or not

installed level may lead to contamination of the measurement

chamber, and will impact accuracy.

Store Elster RABO meters in their original shipping container in a

dry location until installation. If prolonged storage is experienced,

RABO meters should be tested for accuracy before installation.

5. Installation

Elster RABO meters can be installed in horizontal or vertical (top

inlet) piping configurations. Vertical (top inlet) piping is preferred

because it enables the meter to pass contaminants more freely

through the meter. All piping should be properly supported

and aligned to eliminate any strain on the meter, which may cause

the impellers to bind.

Recommended piping practices include a filter or strainer on the

inlet of the meter and non-lubricated isolation valves. A bypass

line will facilitate maintenance and removal of the meter and

provide uninterrupted gas supply.

The meter should not be installed lower than the outlet pipe run.

If it is necessary to install the meter lower than the outlet pipe run,

installation of a drip leg in the outlet piping to capture condensate

is recommended. The meter should never be located at the lowest

point in the system.

A restricting orifice can also be installed at least 4 pipe diameters

downstream of the outlet of the meter to prevent the meter from

flowing excess capacity. Warranty does not cover failures due to

excess flow conditions.

Figure 2. Horizontal installation, side view

Figure 3. Vertical installation, side view

a) Piping Configurations [Figures 2, 3 and 4]

DO NOT weld piping while meter is installed in the

piping system.

If hydro testing, remove the meter from the piping system.

NOTICE

NOTICE

4. Receiving, Handling and Storage

5. Installation

a) Piping Configurations [Figures 2, 3 and 4]

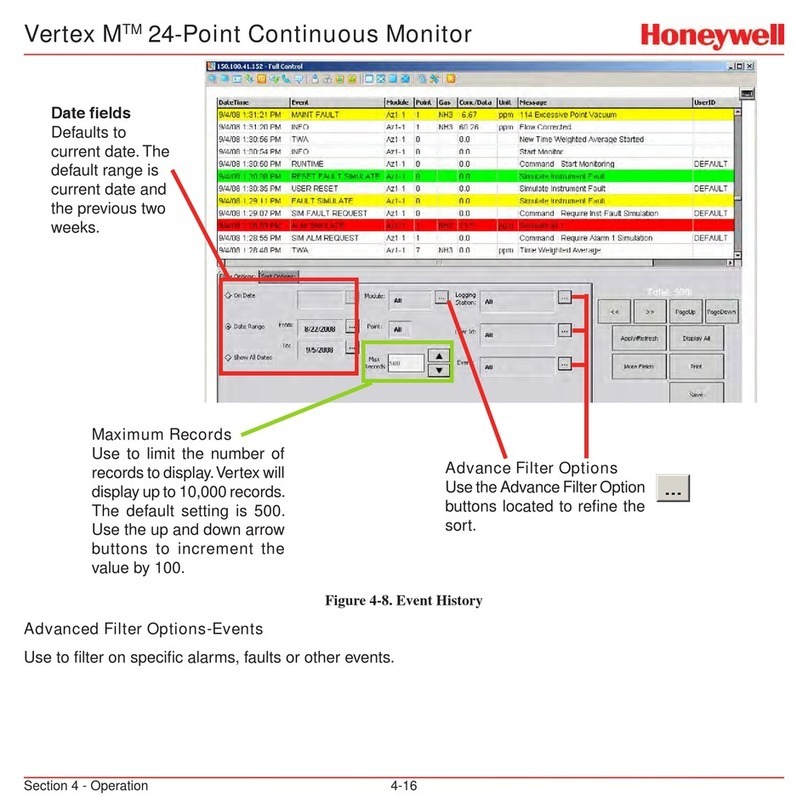

Figure 2. Horizontal installation, side view

Figure 3. Vertical installation, side view

Elster RABO meters should be handled with care to protect the

product from damage. If the package shows evidence of damage

through mishandling in transit, you should notify the shipper

immediately, file a claim with the carrier and notify your Elster

supplier.

Damage to internal components may occur without visible

external damage. All new meters should be inspected and

checked for free rotation of the impellers by lightly blowing

into the inlet of the meter. This slight air pressure should

cause the impellers to rotate freely and come to a stop slowly.

DO NOT attempt to make any repairs. Tampering with the

meter may void warranty coverage.

If a meter shows signs of external damage, or if the impellers do

not rotate freely, contact your local Elster sales representative for

return instructions.

Elster RABO meters are supplied with oil in a separate container.

A material safety data sheet (MSDS) is available upon request.DO

NOT put oil in the meter until it is installed and leveled in the gas

piping system. Meters containing oil that are transported or not

installed level may lead to contamination of the measurement

chamber, and will impact accuracy.

Store Elster RABO meters in their original shipping container in a

dry location until installation. If prolonged storage is experienced,

RABO meters should be tested for accuracy before installation.

Elster RABO meters can be installed in horizontal or vertical (top

inlet) piping configurations. Vertical (top inlet) piping is preferred

because it enables the meter to pass contaminants more freely

through the meter. All piping should be properly supported

and aligned to eliminate any strain on the meter, which may cause

the impellers to bind.

Recommended piping practices include a filter or strainer on the

inlet of the meter and non-lubricated isolation valves. A bypass

line will facilitate maintenance and removal of the meter and

provide uninterrupted gas supply.

The meter should not be installed lower than the outlet pipe run.

If it is necessary to install the meter lower than the outlet pipe run,

installation of a drip leg in the outlet piping to capture condensate

is recommended. The meter should never be located at the lowest

point in the system.

A restricting orifice can also be installed at least 4 pipe diameters

downstream of the outlet of the meter to prevent the meter from

flowing excess capacity. Warranty does not cover failures due to

excess flow conditions.

DO NOT weld piping while meter is installed in the

piping system.

If hydro testing, remove the meter from the piping system.