162847-0001 Rev J 10/15 © 2009-2015 Honeywell International Inc. All Rights Reserved. Page 2

Connecting the Vehicle Electrical Connection

Please review the proper wiring illustration, later in this document, before beginning power cable install. If connecting a VMC, the com-

puter must be powered off. If connecting a HHC cradle/dock, the cradle must be empty.

1. Connect the power cable to the VMC or the HHC cradle.

2. Route the cable from the VMC or HHC cradle to the DC-to-DC converter and, optionally for some VMCs, to the screen blanking box.

3. Cut the cable to length and strip the wire ends. If the screen blanking feature is not used for the Thor VX8 or Thor VX9, do not strip

the green and yellow wires.

4. Route the power cable the shortest way possible. The cable is rated for a maximum temperature of 105°C (221°F). When routing

this cable, it should be protected from physical damage and from surfaces that might exceed this temperature. Do not expose the

cable to chemicals or oil that may cause the wiring insulation to deteriorate. Always route the cable so that it does not interfere with

safe operation and maintenance of the vehicle.

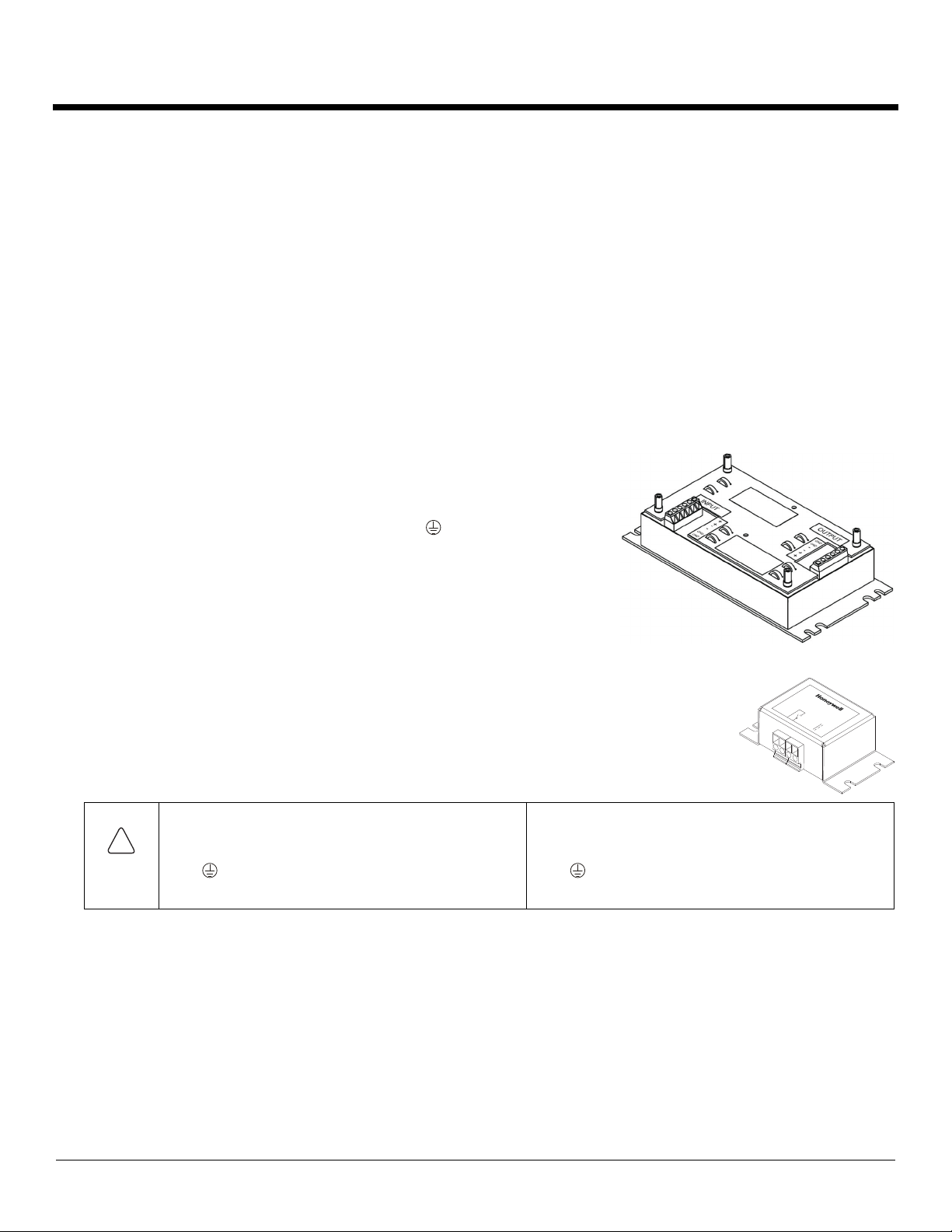

5. Remove the lid from the DC-to-DC converter.

6. Strip the ends of the wires in the cable from the VMC or HHC cradle and attach the wire ends to the output side of the DC-to-DC

converter.

7. Strip the ends of the wires in the cable that will connect to vehicle power and attach

the wire ends to the input side of the DC-to-DC converter.

Note: The input and output blocks each have two + and two – minus connectors.

Either connector in the block can be used to connect the matching polarity wire.

The input and output blocks also each have two (chassis

ground).connections. When the diagram indicates a chassis ground

connection, use either chassis ground connector in each block.

Note: Wire colors depend on the type of device attached. Please refer to the

illustrations later in this document for wire colors.

8. Use looms and wire ties to secure all wiring as shown.

9. Reattach the cover with the screws.

10. If the screen blanking box is used for a Thor VX8 or Thor VX9 installation, attach the stripped green and

yellow wire ends to the box. Refer to the applicable following diagram for proper wiring connection.

11. If the screen blanking box is used for a Thor VM1 or Thor VM2 installation, connect a serial cable from

the COM port on the Mount Smart Dock to the box. Refer to the applicable following diagram for proper

wiring connection.

12. Connect the DC-to-DC converter to the vehicle’s electrical system.

13. While observing the fuse requirements specified above, connect the power cable as close as possible to the actual battery terminals

of the vehicle. When available, always connect to unswitched terminals in the vehicle fuse panel, after providing proper fusing.

ATTENTION:For uninterrupted power, electrical supply connections should not be made at any point after the ignition

switch of the vehicle.

14. If the screen blanking box is used for a VMC installation, connect the box to vehicle motion circuitry and ground. Refer to the

applicable following diagram and the label on the screen blanking box for proper wiring connection.

15. Use proper electrical and mechanical fastening means for terminating the cable. Properly sized “crimp” type electrical terminals are

an accepted method of termination. Select electrical connectors sized for use with 18AWG (1mm2) conductors.

16. Provide mechanical support for the cable by securing it to the vehicle structure at approximately one foot intervals, taking care not to

over tighten and pinch conductors or penetrate the outer cable jacket.

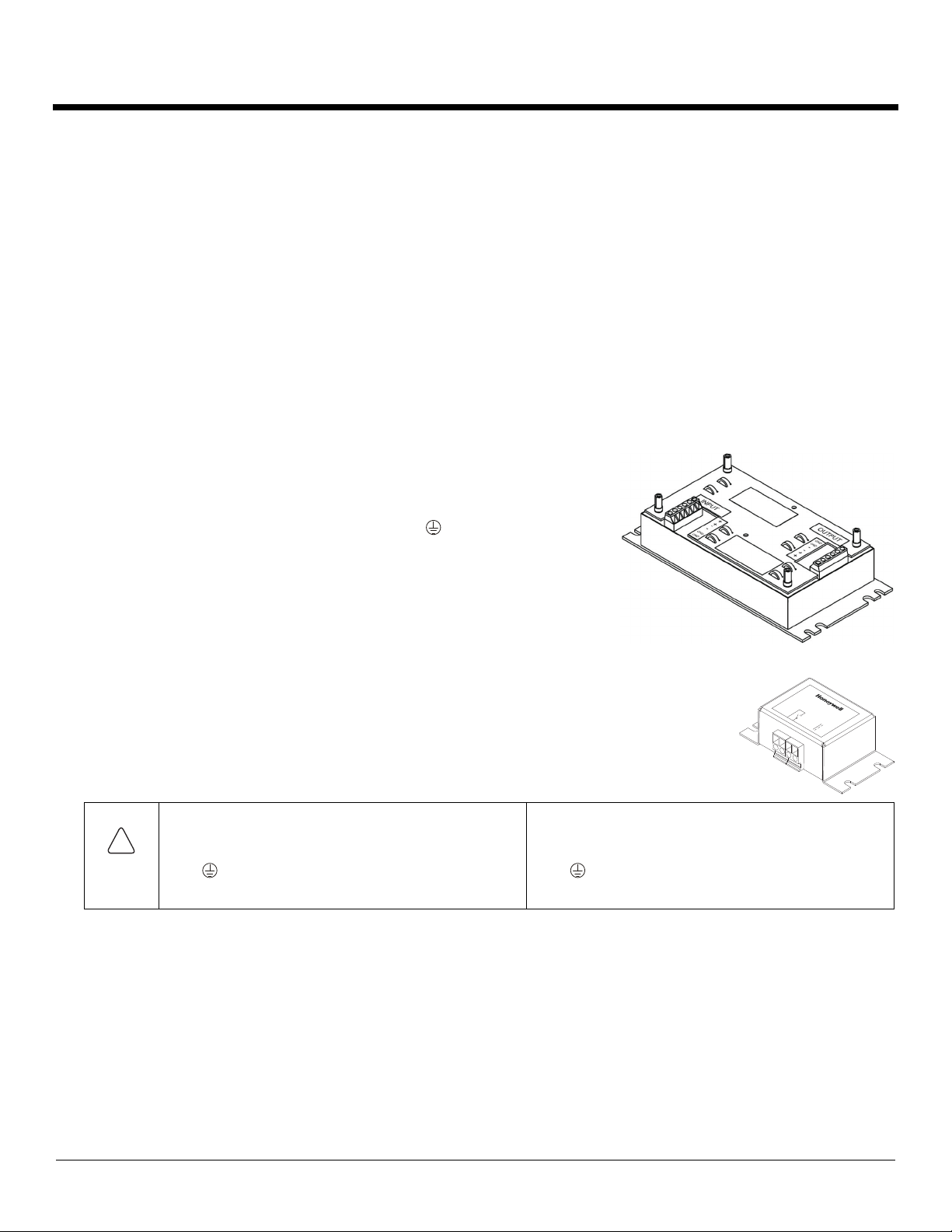

Caution: For battery powered vehicles:

+ is connected to battery positive.

- must be connected to battery negative.

GND must be connected to the vehicle chassis

ground.

For internal combustion engine powered vehicles:

+ is connected to battery positive.

- is connected to battery negative.

GND is connected to the vehicle chassis ground,

which can also be battery negative.

GN D

12-72V