10

Battery Safety

• Only connect the battery clips to a 12 volt DC power supply.

• Don’t use a battery that looks damaged or is leaking.

• Don’t use a machine with damaged battery leads.

• Don’t smoke or allow naked ames anywhere near the battery.

• Don’t let any metal objects come in contact with the battery as

these could cause a spark and possibly make the battery explode.

• Don’t remove the power leads while the machine is running.

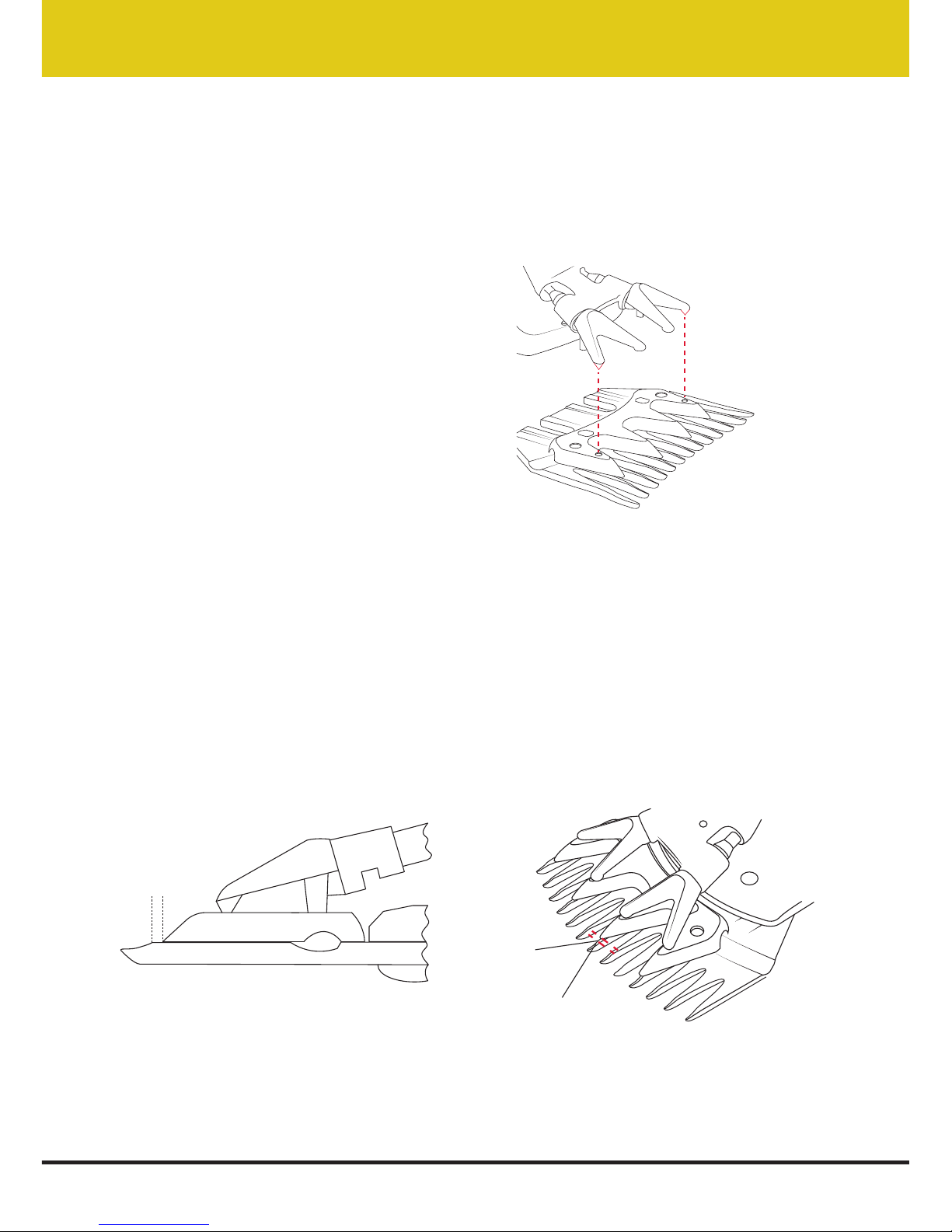

To connect your machine to a battery

1. Make sure your machine is switched o.

2. Connect the black lead to the negative (-) terminal on the battery.

3. Connect the red lead to the positive (+) terminal on the battery.

To disconnect your machine from the battery

1. Make sure your machine is switched o.

2. Remove the red lead from the positive (+) terminal on the battery.

3. Remove the black lead from negative (-) terminal on the battery.

Running the machine directly from a vehicle

• If you are using the machine connected to a vehicle it is

advisable to start the vehicle every 2/3 hours for approximately

15 minutes to top up the battery.

• There is no need to disconnect the battery from the vehicle

when using the machine.

• The vehicle does not need to be running whilst using the

machine.

RAMBO VEHICLE