2

Reference Information � � � � � � � � � � � � � � � � � � 2

Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

. . . . . . . . . . . . . . . . .3

Tire Pressure Table. . . . . . . . . . . . . . . . . . . . . . . .3

. . . . . . . . . . . .3

California Proposition 65 . . . . . . . . . . . . . . . . . . .4

Assembly Safety � � � � � � � � � � � � � � � � � � � � � � � 4

Bolt Torque Table . . . . . . . . . . . . . . . . . . . . . . . . .5

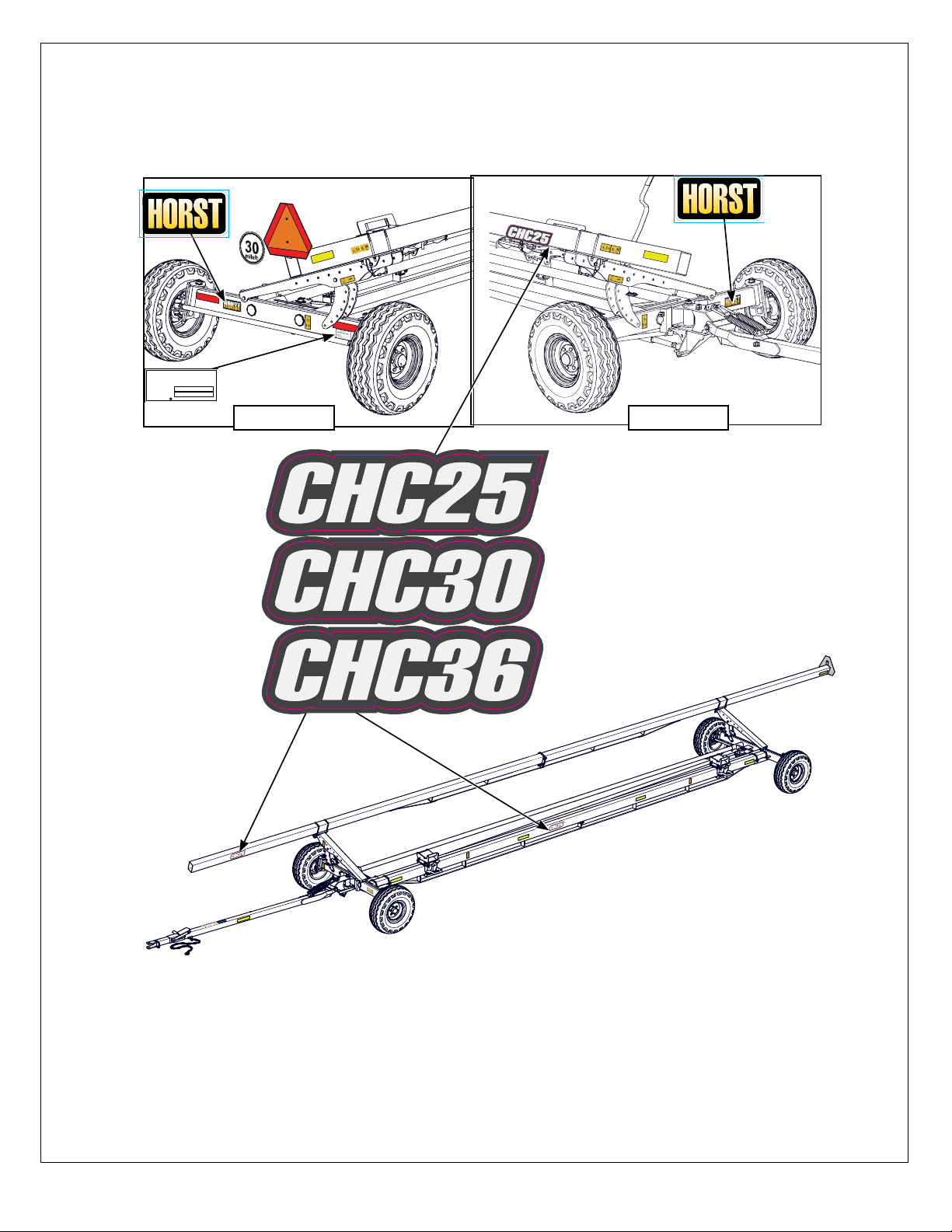

Label Layout CHC Series . . . . . . . . . . . . . . . . . . .6

Product labels and Serial Plate . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . 6

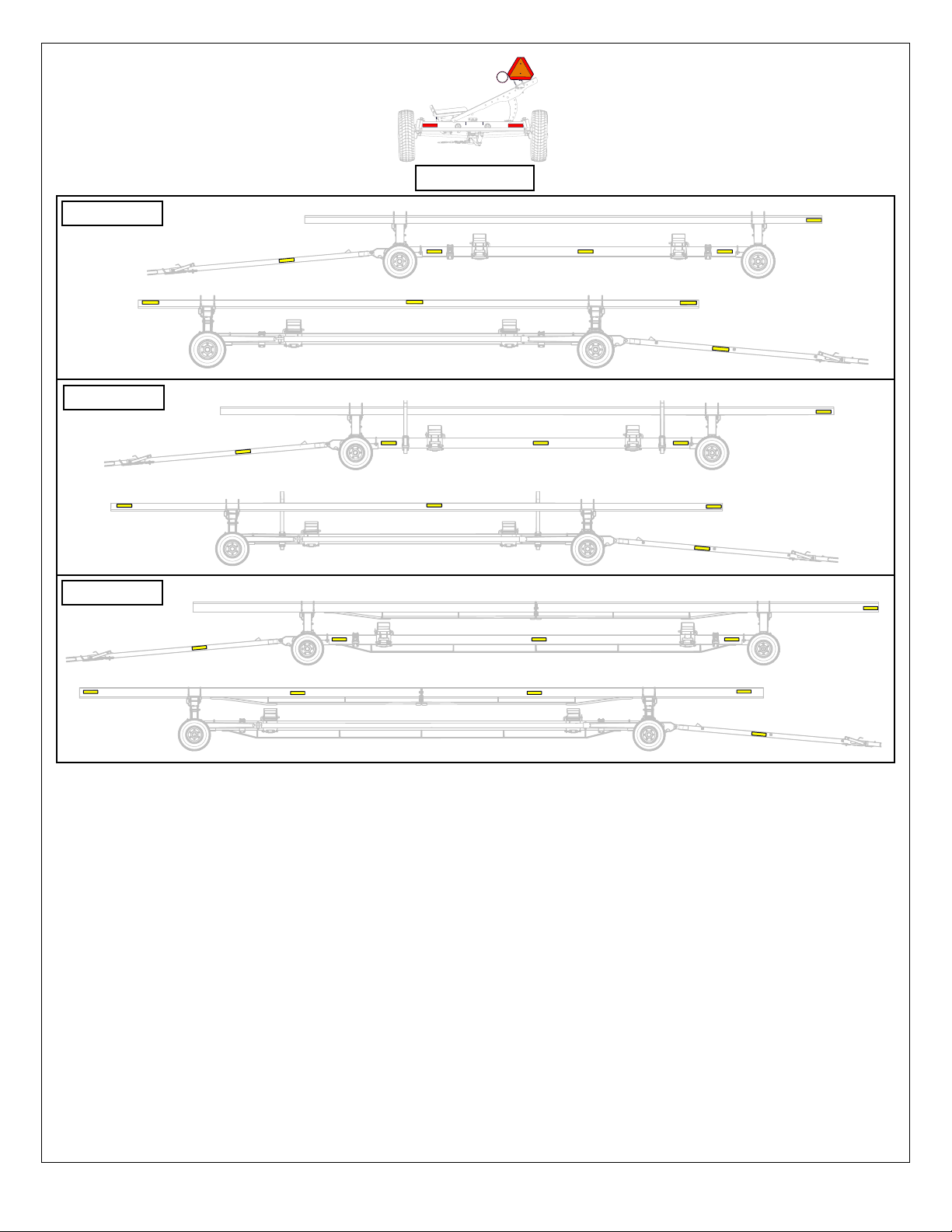

Safety Label Layout . . . . . . . . . . . . . . . . . . . . . . . . . 7

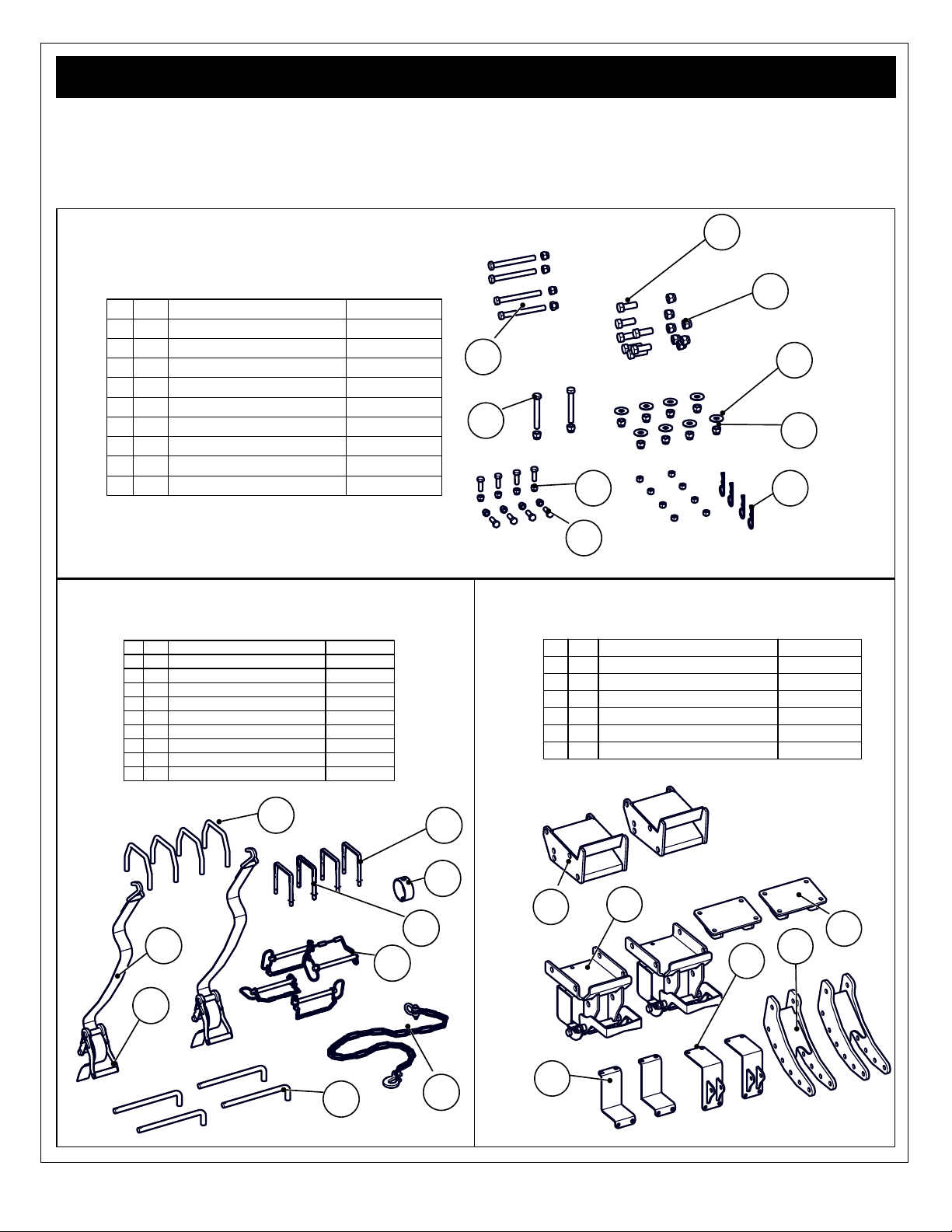

Parts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Hardware Bag. . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Parts Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Crated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Chassis Parts . . . . . . . . . . . . . . . . . . . . . . . . . .10

Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

STEP 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Reach & Bottom Rail. . . . . . . . . . . . . . . . . . . . . . . . 11

STEP 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Mount Tongue Assembly: . . . . . . . . . . . . . . . . . . . . 12

Safety Chain: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

STEP 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Diagonal Channels . . . . . . . . . . . . . . . . . . . . . . . . . 13

STEP 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Top Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . 14

. . . . . . . . . . . . . 14

STEP 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Ratchet Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Header Pad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Accessories � � � � � � � � � � � � � � � � � � � � � � � � � � 16

Tongue Spring Balancer Kits Assembly . . . . . . .16

Tongue Spring Balancer - Wagon Models. . . . . . . . 16

LK Series Road Signal Kit . . . . . . . . . . . . . . . . .17

Rear: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Front:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Reach Tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . .18

. . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CHC Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 18

HBAFK Honey Bee AirFLEX®Pad Adapter Kit . .19

Whats Included: . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Honey Bee AirFLEX®Adapter . . . . . . . . . . . . . . . . . 19

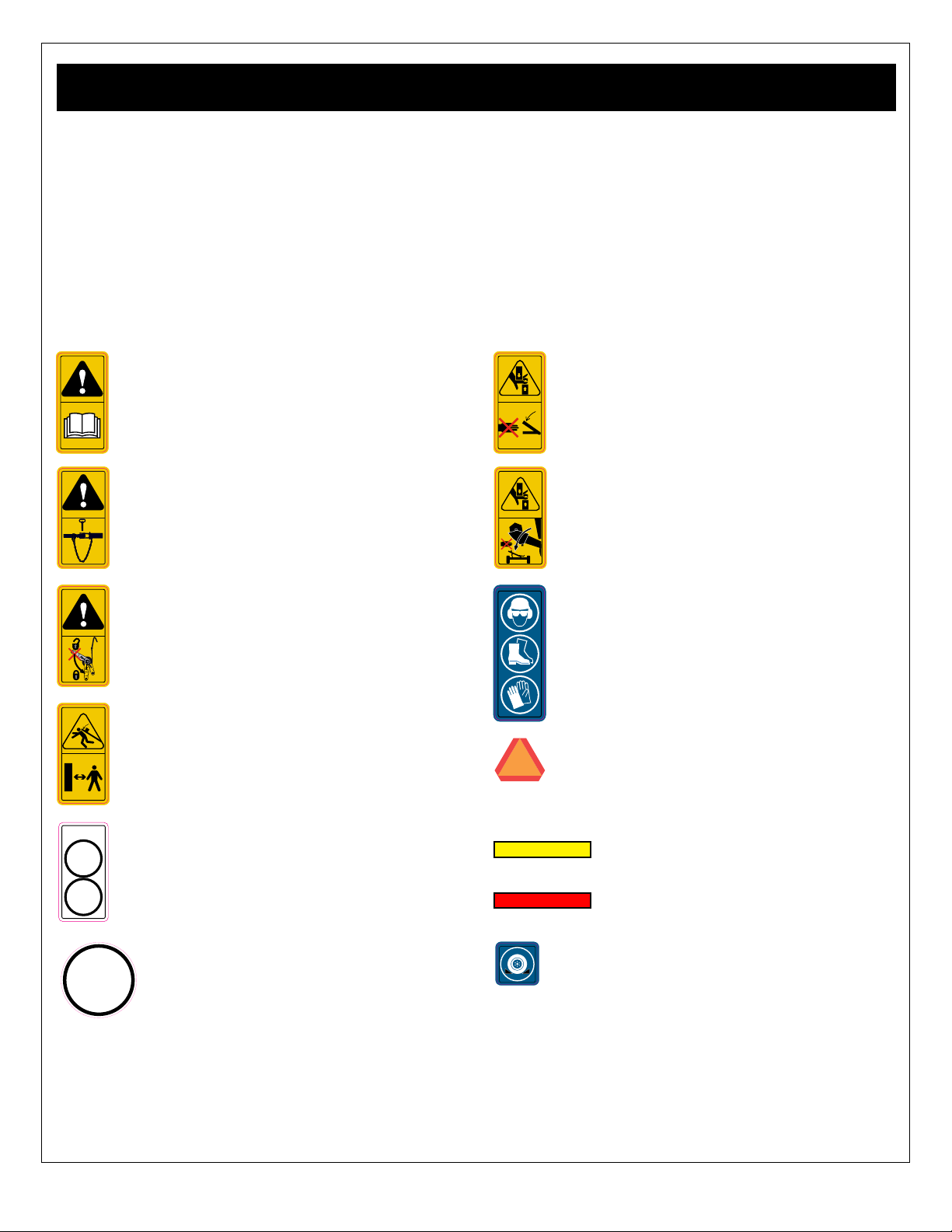

CAUTION

Prepare

Read and understand ALL safety and

operating instructions in the owner

manual, read and understand ALL

safety labels located on the machine.

SL00004

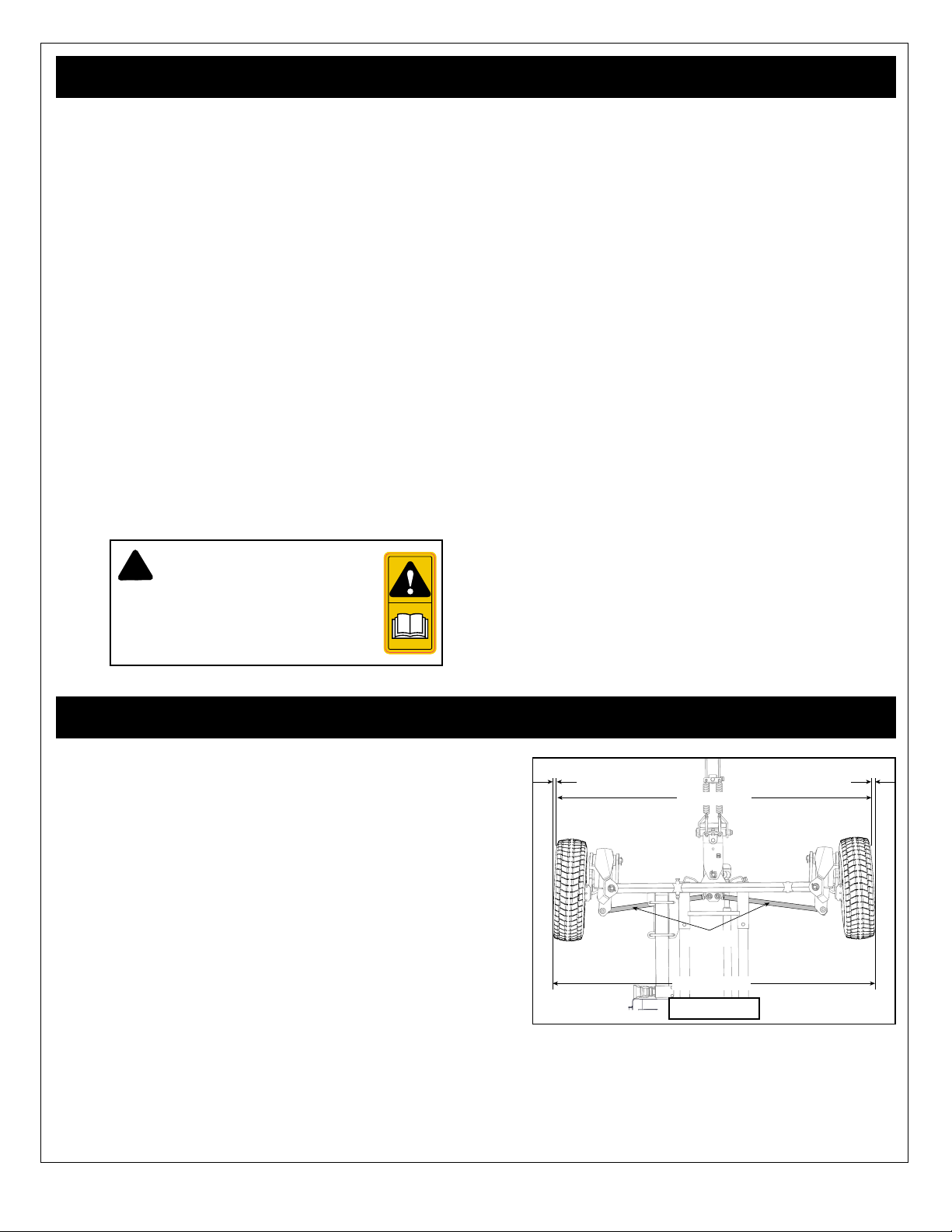

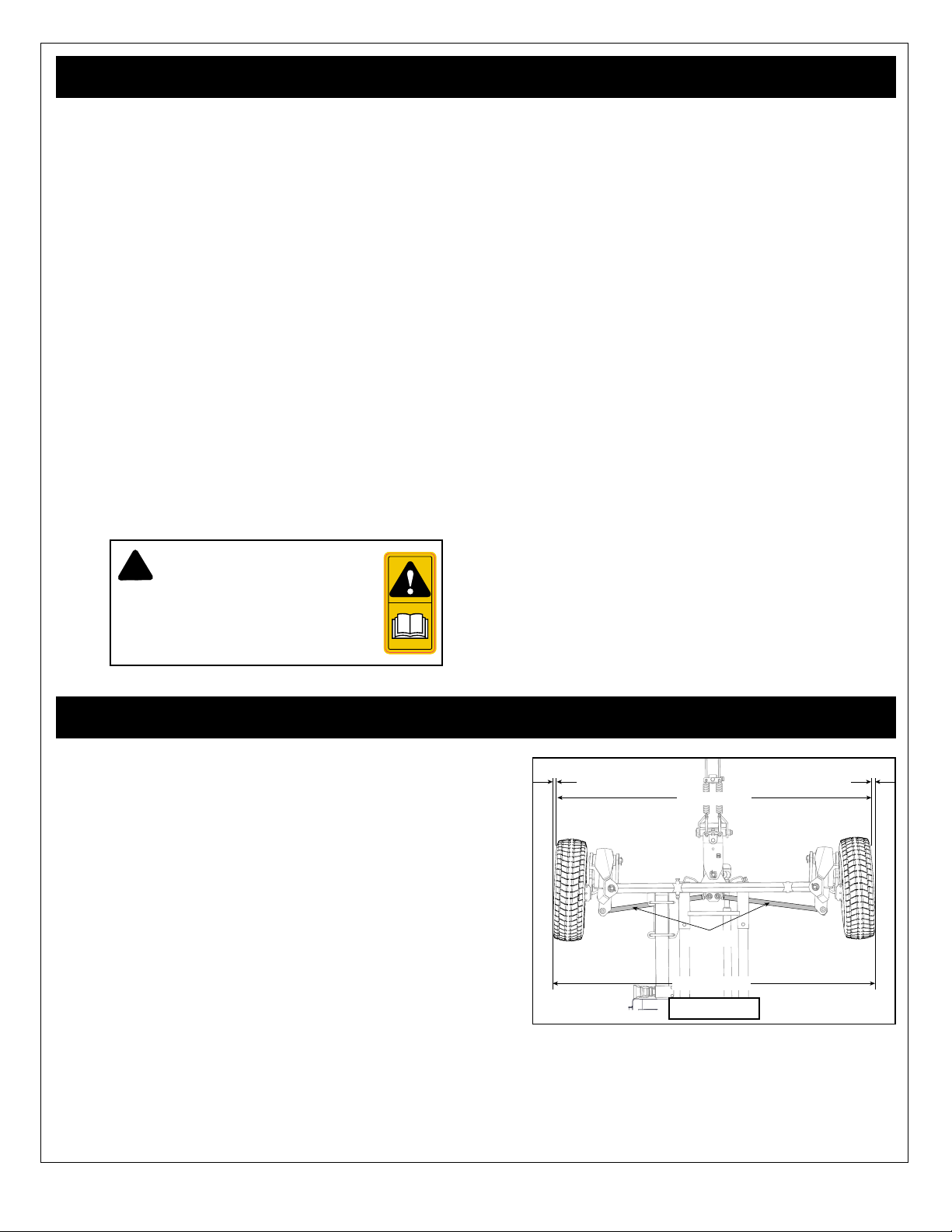

Alignment is set at the factory with proper toe-in settings on the front

steering axles. Check alignment as outlined below.

To check toe-in:

• Position the tongue parallel to the reach tubes

• Run a string or straight edge from front to back along the outside

of the front and rear wheels, check both sides.

•

• Measure across the front of the wheels, - dimension A

• Then across the back of the wheels, - dimension B.

• Dimension A measurement should be approximately 0.32 -

If adjustment is required, loosen the tie rod end jam nuts, then:

• Adjust as required by turning the two tie rods.

•

0.6cm - 0.32cm

1/16” - 1/8”

0.16cm - 0.32cm

1/16” - 1/8”

Dimension A

Dimension B

Tie Rods

Front axle