5

Safety

Introduction & Safety Information

Thank you for purchasing this Pressure Washer. We

reserve the right to make changes at any time

without incurring any obligation.

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result causing

property damage, personal injury or death.

AVERTISSEMENT: Si ces directives ne sont pas

suivies à la lettre, un incendie ou une explosion

pourrait survenir et entraîner des dommages à la

propriété, des lésions corporelles ou la mort.

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

Owner/User Responsibility

The owner and/or user must have an understanding of the

manufacturer’s operating instructions and warnings before

using this pressure washer. Warning information should

be emphasized and understood. If the operator is not

fluent in English, the manufacturer’s instructions and

warnings shall be read to and discussed with the operator

in the operator’s native language by the purchaser/owner,

making sure that the operator comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

The operator must know how to stop the machine quickly

and understand the operation of all controls.

SAVE THESE INSTRUCTIONS

This manual should be considered a permanent part

of the machine and should remain with it if machine is

resold.

When ordering parts, please specify model and

serial number. Use only identical replacement parts.

This machine is to be used only by trained operators.

IMPORTANT SAFETY INFORMATION

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result, causing

property damage, personal injury or loss of life.

AVERTISSEMENT: Si ces directives ne sont pas

suivies à la lettre, un incendie ou une explosion

pourrait survenir et entraîner des dommages à la

propriété, des lésions corporelles ou la mort.

WARNING: To reduce the risk of

injury, read operating instructions

carefully before using.

AVERTISSEMENT: Pour réduire le

risque de blessures, lire attentive-

ment les instructions de fonctionne-

ment avant l'utilisation.

1. Read the owner's manual thor-

oughly. Failure to follow instruc-

tions and warnings could cause

malfunction of the machine and result in death,

serious bodily injury and/or property damage.

2. Know how to stop the machine and bleed pressure

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

4. Use only your hand to push in or turn the gas control

knob. Never use a tool. If the knob will not push in or

turn by hand, don't try to repair it; call a qualified

service technician.

5. All installations must comply with local codes. Contact

your electrician, plumber, utility company or the

selling dealer for specific details.

WARNING: Use vapor fuel only.

AVERTISSEMENT: Utiliser des vapeurs de carburant

seulement

WARNING: Must be plugged into properly wired three

hole grounded outlet that accommodates plug on

power cord. Failure to comply could result in elec-

trical shock.

AVERTISSEMENT: Doit être raccordé dans une sortie

à trois trous mise à la masse et correctement câblée

qui peut accueillir une fiche sur un cordon

d'alimentation.

WARNING: To reduce the risk of electric shock,

disconnect all electrical connections and shut-off gas

valve before servicing.

AVERTISSEMENT: Pour réduire le risque de choc

électrique, débrancher toutes les connexions

électriques et la soupape de coupure des gaz avant

d'effectuer des opérations d'entretien.

Hotsy 900/1400 Series Dealer Manual 9.803-324.0 - AW

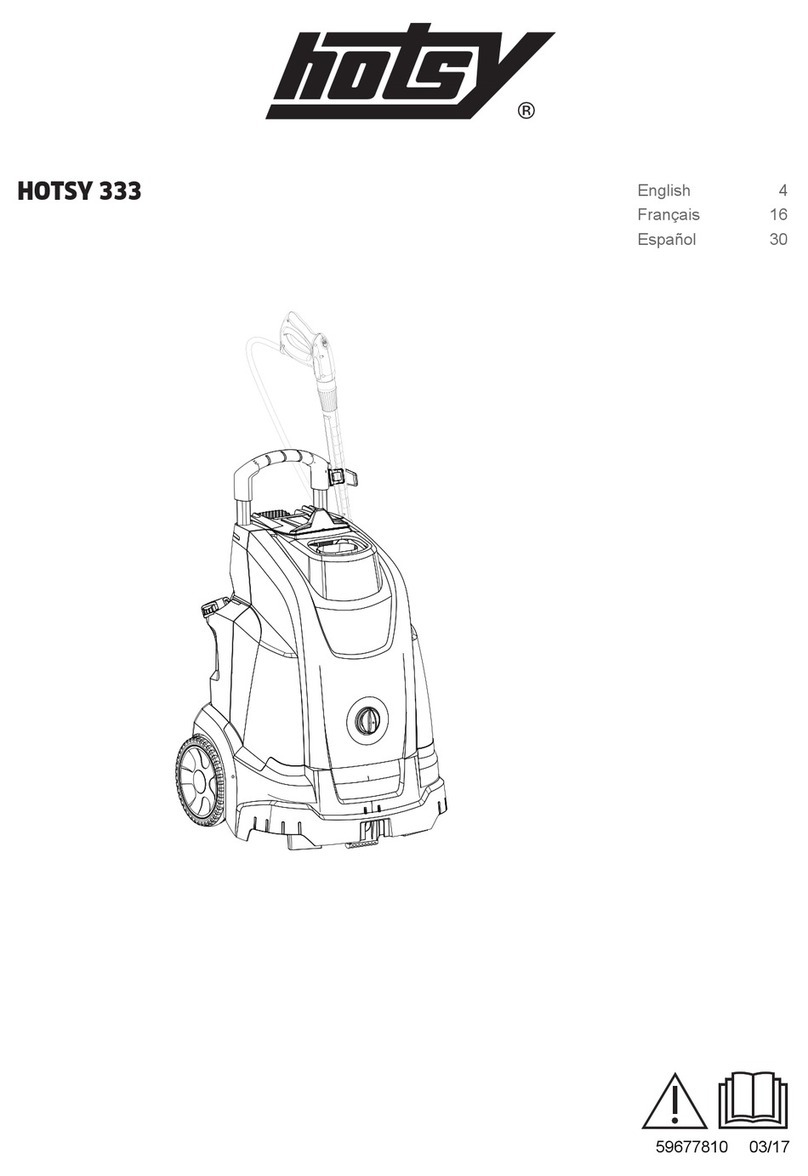

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

OPERATIONS

SAFETY

MAINTENANCE