–If the operator is not fluent in English,

the manufacturer’s instructions and

warnings shall be read to and dis-

cussed with the operator in the opera-

tor’s native language by the purchaser/

owner, making sure that the operator

comprehends its contents.

–Owner and/or user must study and

maintain for future reference the manu-

facturers’ instructions.

This product must be grounded. If it should

malfunction or breakdown, grounding pro-

vides a path of least resistance for electric

current to reduce the risk of electric shock.

This product is equipped with a cord having

an equipment-grounding conductor and a

grounding plug. The plug must be plugged

into an appropriate outlet that is properly in-

stalled and grounded in accordance with all

local codes and ordinances.

DANGER

Improper connection of the equipment-

grounding conductor can result in a risk of

electrocution. Check with a qualified electri-

cian or service personnel if you are in doubt

as to whether the outlet is properly ground-

ed. Do not modify the plug provided with

the product - if it will not fit the outlet, have

a proper outlet installed by a qualified elec-

trician. Do not use any type of adapter with

this product.

This product is supplied with a Ground

Fault Circuit Interrupter (GFCI) built into the

power cord plug. This device provides addi-

tional protection from the risk of electric

shock. If power is interrupted in the line, the

GFCI will automatically re-close the circuit

to the load after power is restored. Depend-

ing on the GFCI model, it may be neces-

sary to manually operate the reset button to

restore power to the GFCI load circuit. If re-

placement of the plug or cord is needed use

identical replacement parts.

몇CAUTION

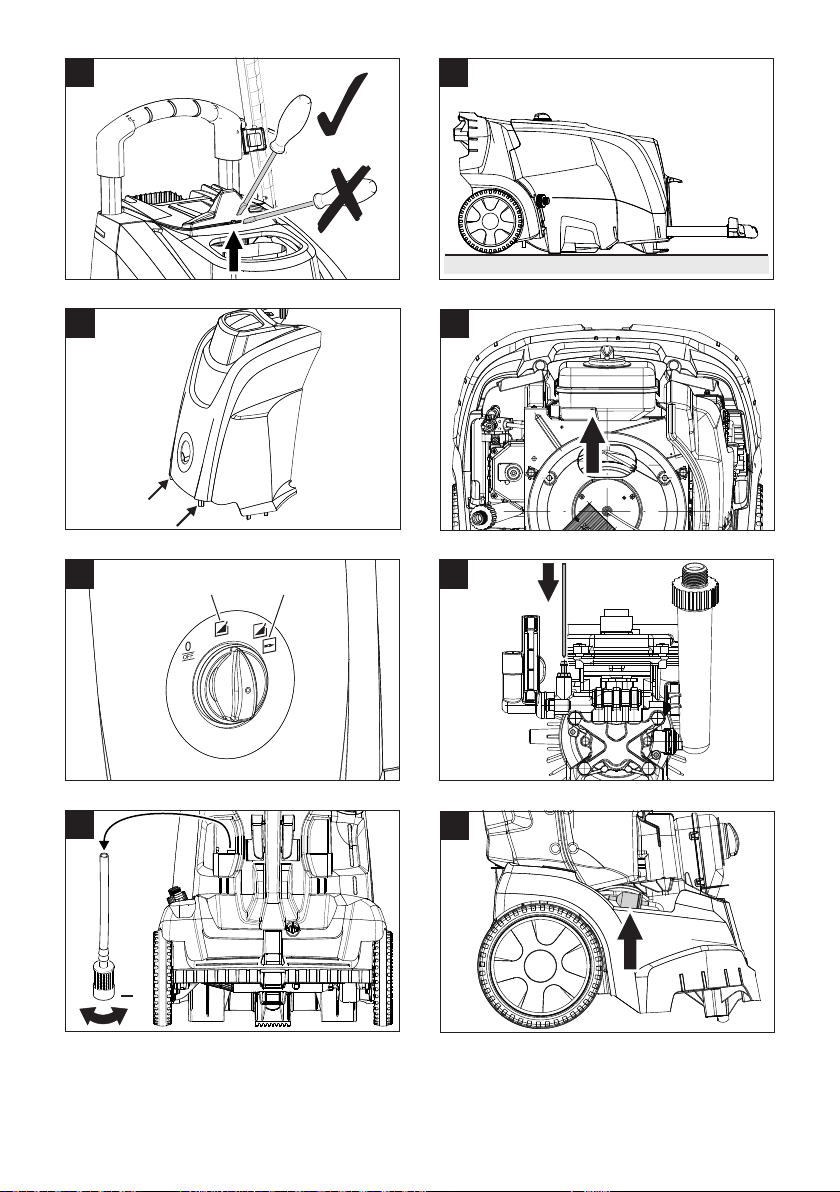

When connecting the water inlet to the wa-

ter supply mains, local regulations of your

water company must be observed. In some

areas the unit must not be connected di-

rectly to the public drinking water supply.

This is to ensure that there is no feedback

of chemicals into the water supply. Direct

connection via a receiver tank or backflow

preventer, for example, is permitted.

Always connect the system separator to

the water supply, never directly to the appli-

ance!

Dirt in the feed water will damage the unit.

To avoid this risk, we recommend fitting a

water filter.

–Garden hose must be at least 1/2 inch

in diameter.

–Flow rate of water supply must not fall

below 2.5 GPM (gallons per minute).

–Flow rate can be determined by running

the water for one minute into an empty

5-gallon container.

–The water supply temperature must not

exceed 86°F/30°C.

–Never use the pressure washer to draw

in water contaminated with solvents,

e.g. paint thinners, gasoline, oil, etc.

–Always prevent debris from being

drawn into the unit by using a clean wa-

ter source. Use additional water filter.

SAVE THESE INSTRUCTIONS!

GROUNDING INSTRUCTIONS

GROUND FAULT CIRCUIT

INTERRUPTER PROTECTION

WATER SUPPLY

5EN