6

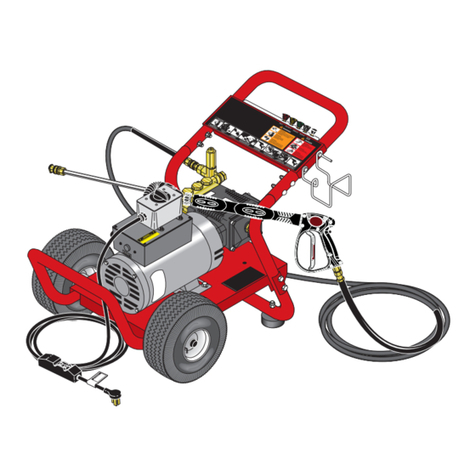

Safety

IMPORTANT SAFETY INFORMATION

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result, causing

property damage, personal injury or loss of life.

AVERTISSEMENT: Si ces directives ne sont pas

suivies à la lettre, un incendie ou une explosion

pourrait survenir et entraîner des dommages à la

propriété, des lésions corporelles ou la mort.

WARNING: To reduce the risk of

injury, read operating instruc-

tions carefully before using.

AVERTISSEMENT:Pourréduirele

risque de blessures, lire atten-

tivement les instructions de

fonctionnement avant l'utilisa-

tion.

1.Read the owner's manual thor-

oughly. Failure to follow instruc-

tions could cause malfunction of the machine and

result in death, serious bodily injury and/or property

damage.

2. Know how to stop the machine and bleed pressure

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

4. All installations must comply with local codes.

Contact your electrician, plumber, utility company or

the selling dealer for specific details.

WARNING: Must be plugged into properly wired

three hole grounded outlet that accommodates

plug on power cord. Failure to comply could result

in electrical shock

AVERTISSEMENT: Doit être raccordé dans une

sortie à trois trous mise à la masse et correctement

câblée qui peut accueillir une fiche sur un cordon

d'alimentation. Le non-respect de cette consigne

pourrait causer un choc électrique.

DANGER: Improper connection of the equipment-

grounding conductor can result in a risk of electro-

cution. Check with a qualified electrician or service

personnel if you are in doubt as to whether the

outlet is properly grounded. Do not modify the plug

provided with the product - if it will not fit the outlet,

have a proper outlet installed by a qualified electri-

cian. Do not use any type of adapter with this

product.

DANGER: Une mauvaise connexion du conducteur

de terre de l'équipement peut entraîner un risque

d'électrocution. Vérifier auprès d'un électricien

qualifié ou du personnel d'entretien si vous avez

des doutes quant à savoir si la sortie est

correctement mise à la masse. Ne pas modifier la

fiche fournie avec le produit - si elle n'entre pas

dans la sortie, faire installer une sortie appropriée

par un électricien qualifié. Ne jamais utiliser un

adaptateur avec ce produit.

DANGER: Keep wand, hose, and

water spray away from electric

wiring or fatal electric shock may

result.

AVERTISSEMENT: Garder la

lance, le boyau et le jet d'eau à

l'écart de tout câblage électrique

ou des chocs électriques mortels

pourraient survenir.

5. To protect the operator from electrical shock, the

machine must be electrically grounded.

It is the responsibility of the owner to connect this

machine to a UL grounded receptacle of proper

voltage and amperage ratings. Do not spray water

on or near electrical components. Do not touch

machine with wet hands or while standing in water.

Always disconnect power before servicing.

WARNING: Flammable liquids can create fumes

which can ignite, causing property damage or

severe injury.

AVERTISSEMENT: Des liquides inflammables

peuvent produire des vapeurs qui peuvent

s'enflammer, causant ainsi des dommages à la

propriété ou des blessures graves.

WARNING: Risk of explosion —

Do not Spray flammable liquids.

Operate only where open flame

or torch is permitted.

AVERTISSEMENT: Risque

d'explosion - Ne pas pulvériser

de liquides inflammables. Utiliser

uniquementdansdes endroits où

l'utilisation d'une flamme nue ou

d'une torche est permise.

WARNING: Risk of fire — Do not

add fuel when the product is

operating or still hot.

AVERTISSEMENT: Risque

d'incendie - Ne pas changer les

réservoirs pendant que le produit

est en marche ou encore chaud.

6.Oil burning appliances shall be

installed only in locations where

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

OPERATIONS

SAFETY

MAINTENANCE

DANGER

KEEP WATER

SPRAY AWAY FROM

ELECTRICAL WIRING.

WARNING

RISK OF EXPLOSION:

IF GAS SMELL

PRESENT TURN OFF

SUPPLY

WARNING

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

MANUAL, OPERATOR, HOTSY, STAT ELECTRIC, OIL 8.916-831.0 - D