INTRODUCTION & SAFETY INFORMATION

WARNING: Flammable liquids

can create fumes which can

ignite causing property damage

or severe injury.

WARNING: Risk of explosion

— do not spray flammable liq-

uids.

5. Risk of explosion - do not spray

flammable liquids or operate in

an explosive location.

WARNING: Keep water spray

away from electric wiring or fa-

tal electric shock may result.

6. To protect the operator from

electrical shock, the machine

must be electrically grounded.

It is the responsibility of the

owner to connect this machine

to a UL grounded receptacle of

proper voltage and amperage ratings. Do not spray

water on or near electrical components. Do not

touch machine with wet hands or while standing in

water. Always disconnect power before servicing.

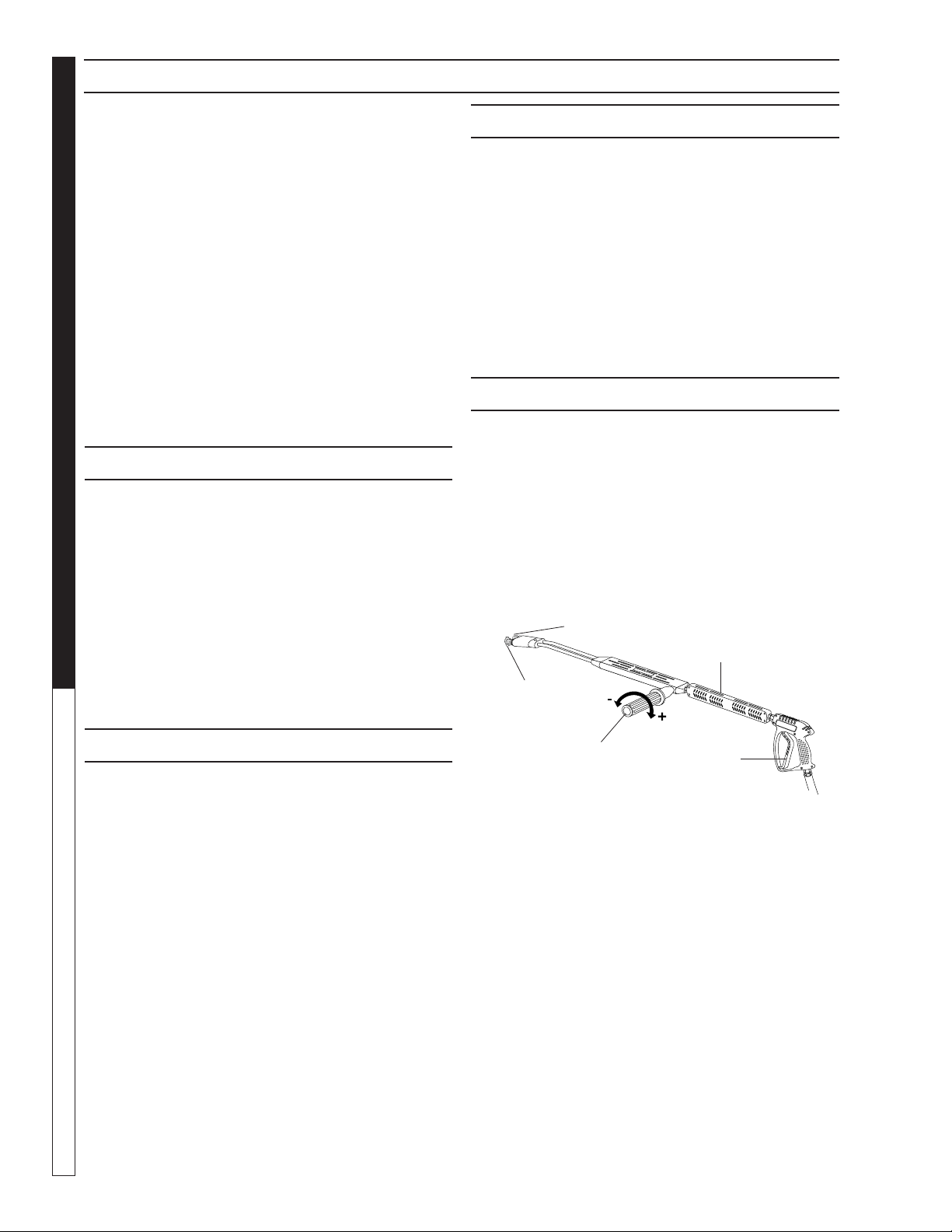

7. Grip cleaning wand securely with both hands before

starting the cleaner. Failure to do this could result

in injury from a whipping wand.

WARNING: The high pressure

stream of fluid that this equip-

ment can produce can pierce

skin and its underlying tissues,

leading to serious injury and

possible amputation.

8. High pressure developed by

these machines will cause per-

sonal injury or equipment dam-

age. Use caution when oper-

ating. Do not direct discharge stream at people, or

severe injury or death will result.

9. Never make adjustments on machine while in

operation.

WARNING: High pressure spray

can cause paint chips or other

particles to become airborne and

fly at high speeds.

10. Eye safety devices and foot

protection must be worn when

using this equipment.

11. Machineswithspraygun should

not be operated with the trigger

in the off position for extensive

periods of time as this may cause damage to the

pump.

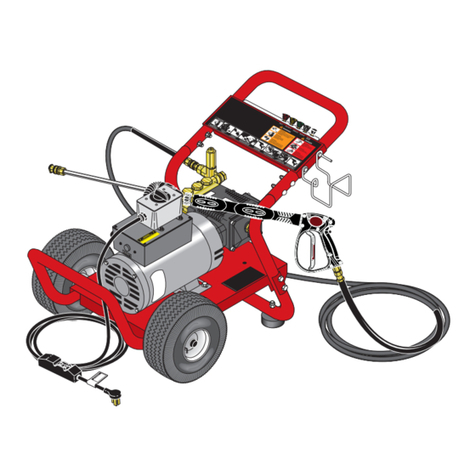

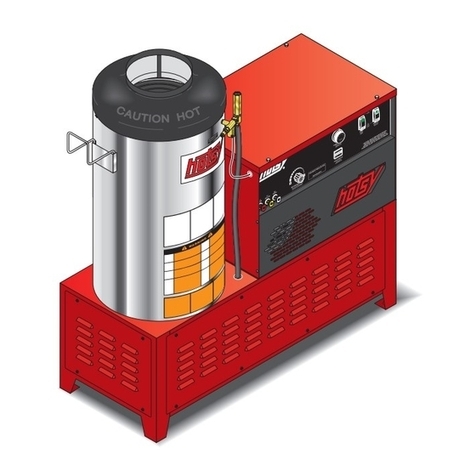

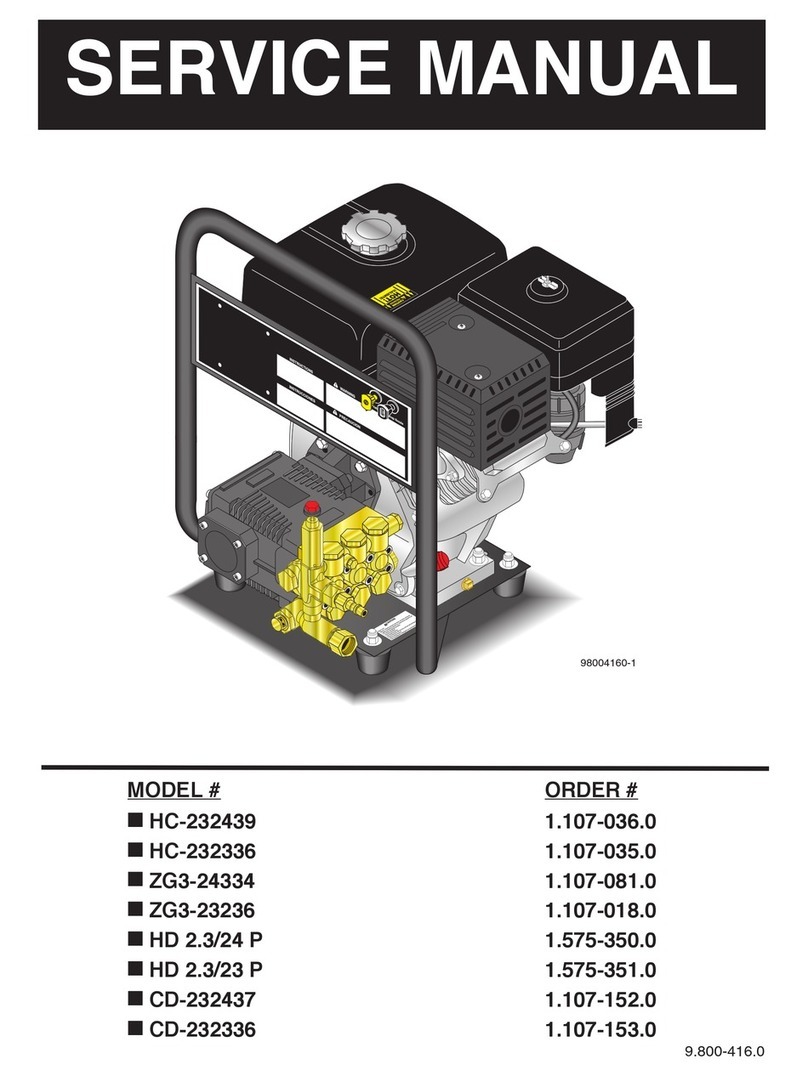

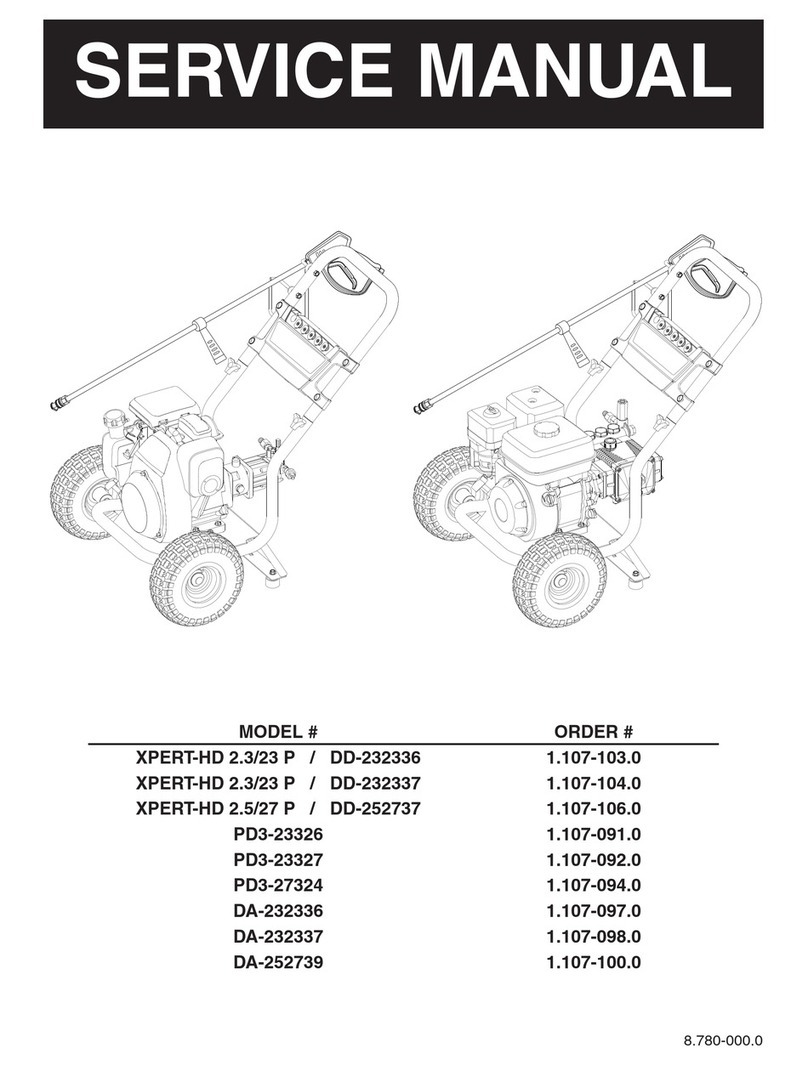

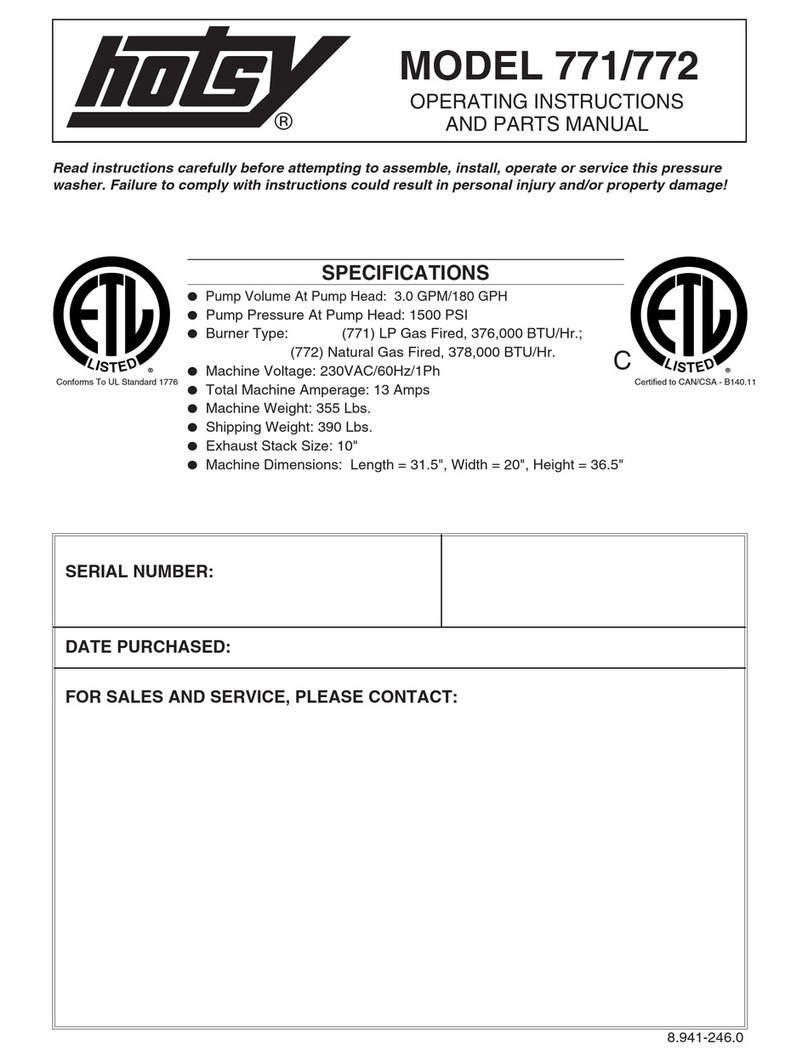

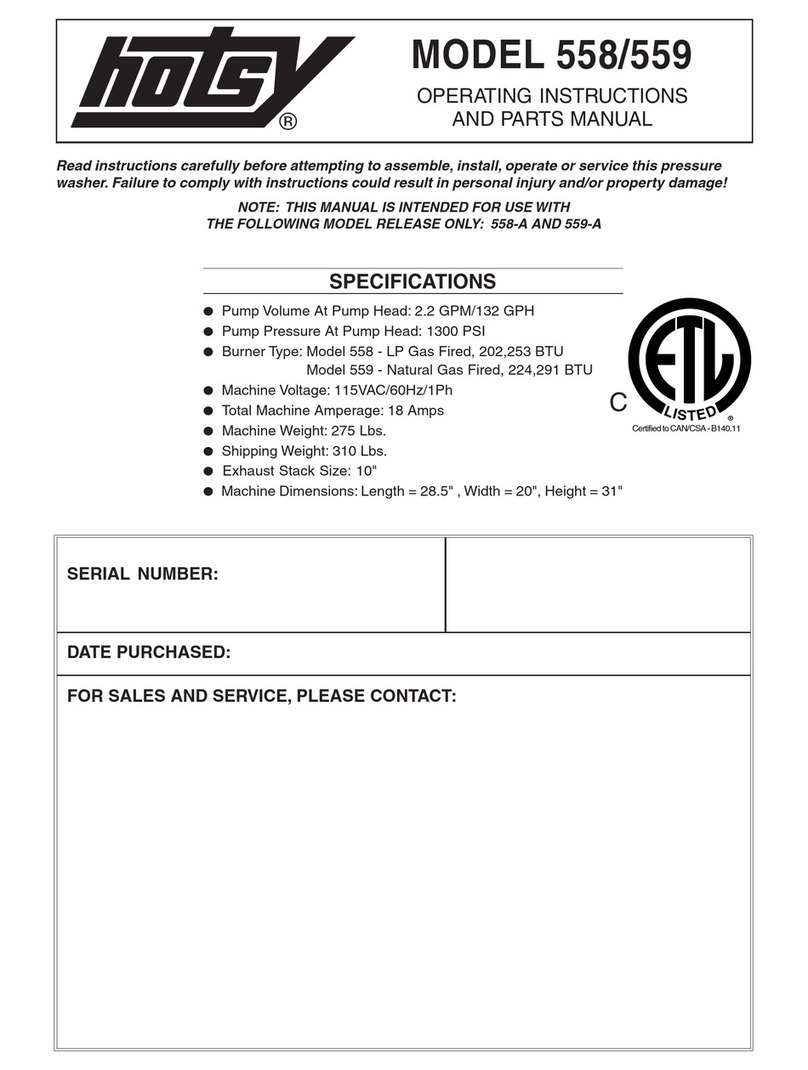

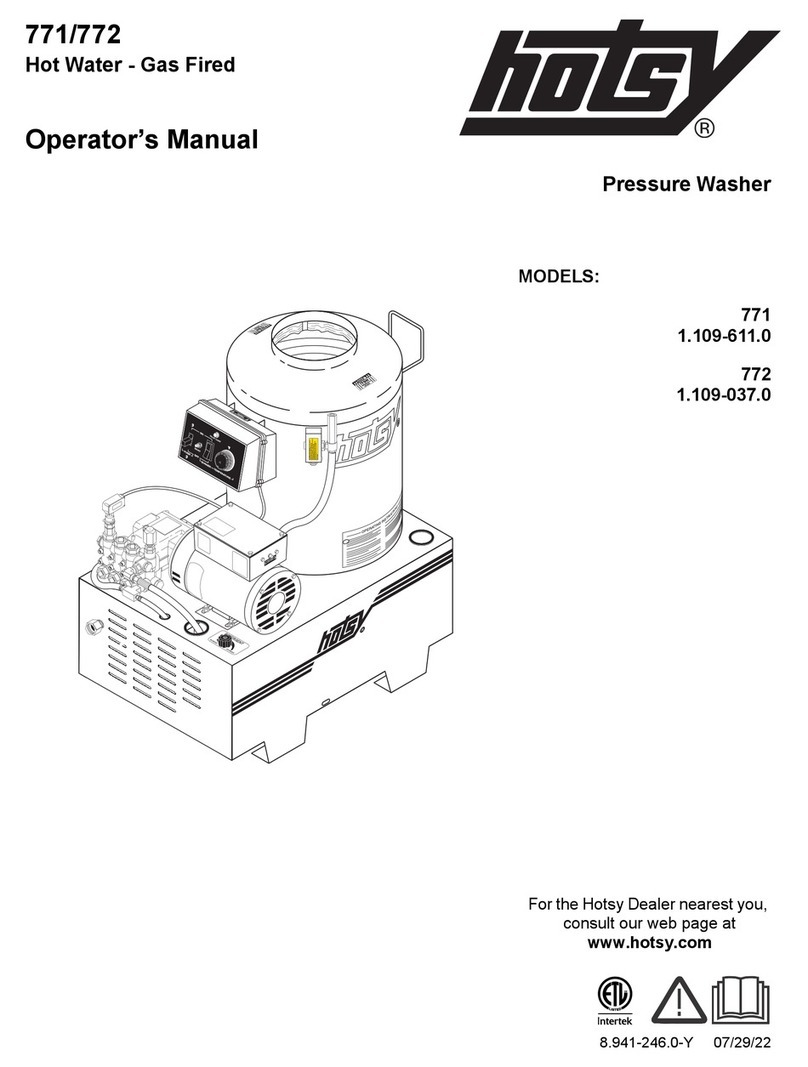

Thank you for purchasing a Hotsy Pressure Washer.

This manual covers the operation and maintenance of

the Hotsy 1700 series washers. All information in this

manual is based on the latest product information avail-

able at the time of printing.

We reserve the right to make changes at any time

without incurring any obligation.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this pressure washer. Warning information

should be emphasized and understood. If the operator

is not fluent in English, the manufacturer’s instructions

and warnings shall be read to and discussed with the

operator in the operator’s native language by the pur-

chaser/owner, making sure that the operator compre-

hends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number.

GENERAL SAFETY

INFORMATION

WARNING: When using this machine basic pre-

cautions should always be followed, including the

following:

CAUTION:To reduce the risk of

injury, read operating instruc-

tions carefully before using.

1. Read the owner's manual

thoroughly. Failure to follow

instructions could cause mal-

function of the machine and

result in death, serious bodily

injury and/or property dam-

age.

2. Know how to stop the machine and bleed pressures

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

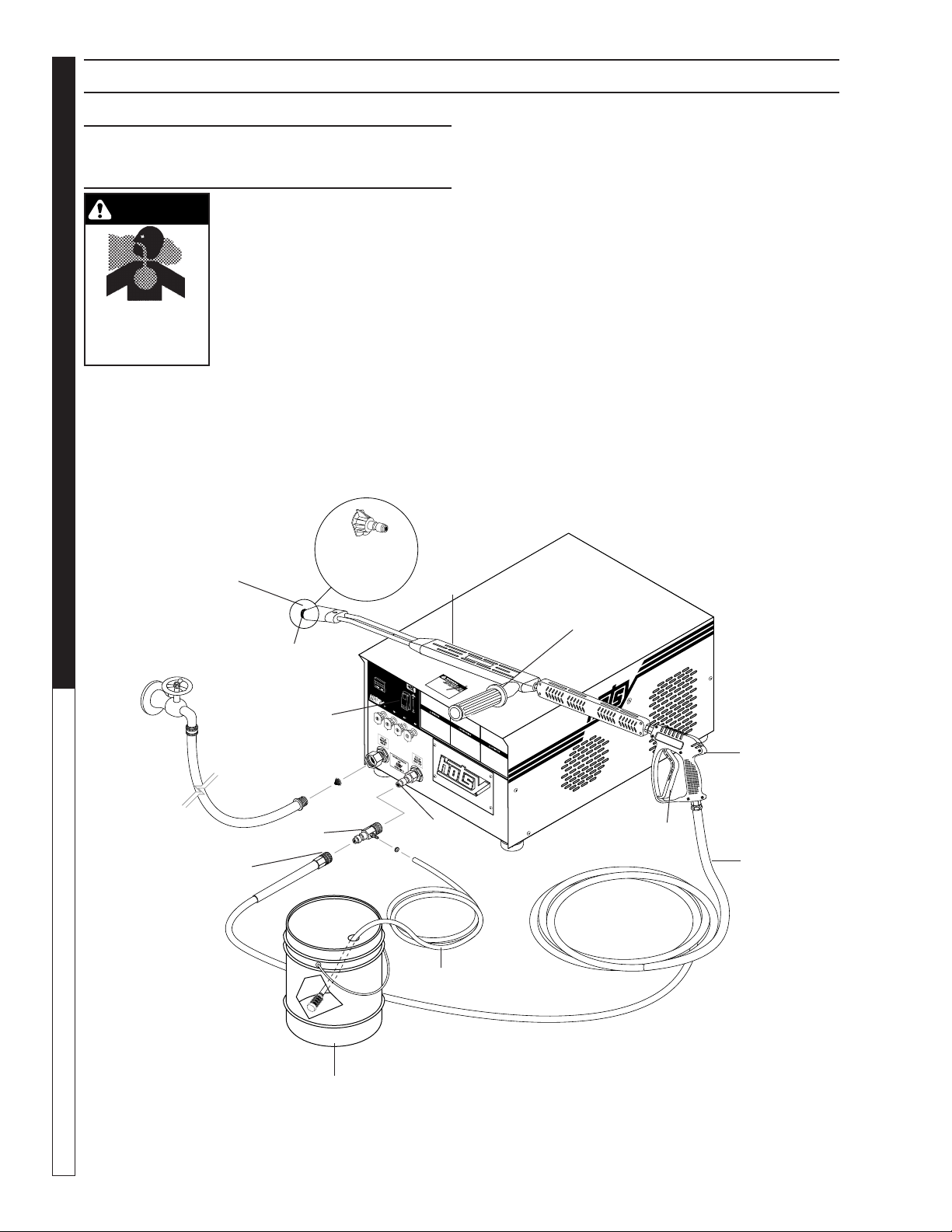

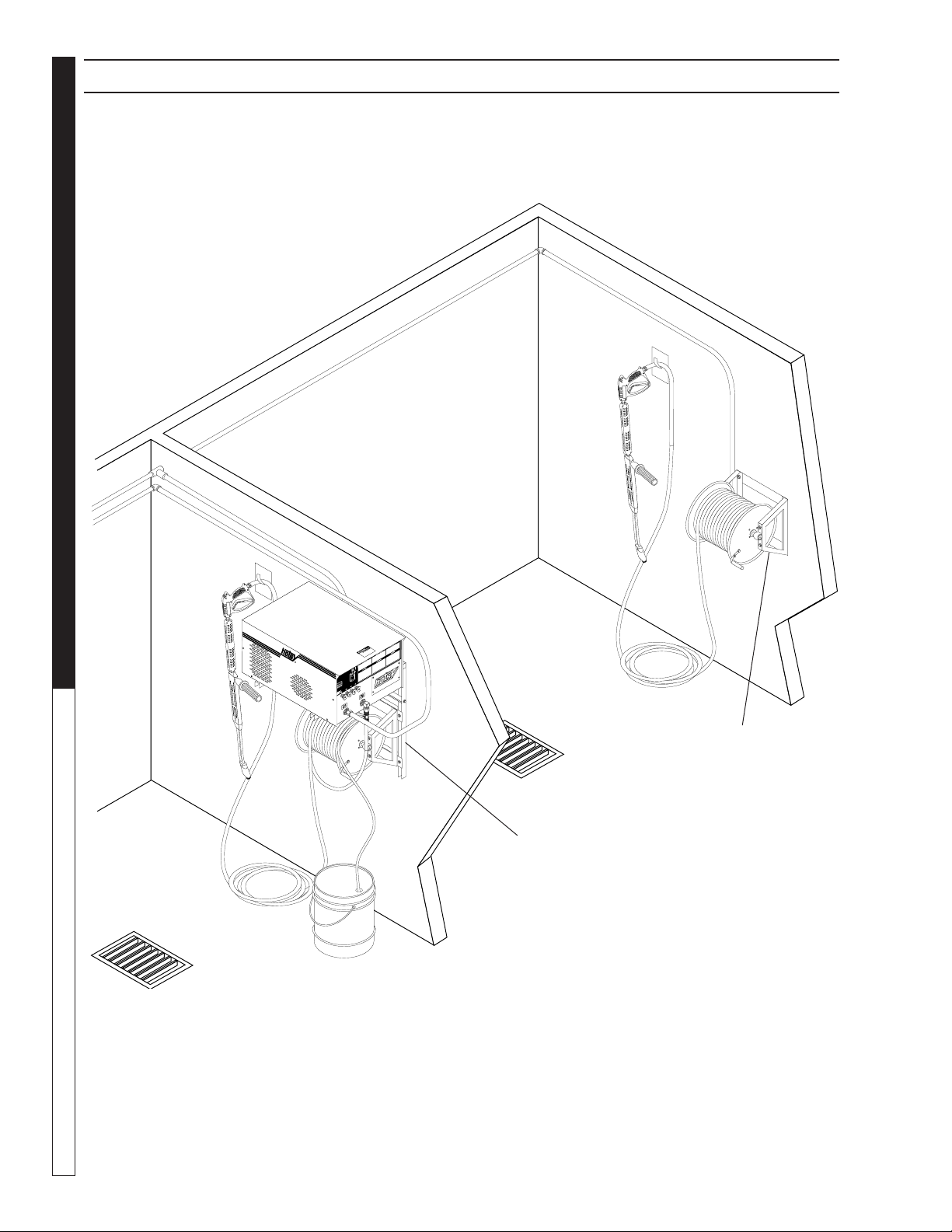

4. All installations must comply with local codes. Con-

tact your electrician, plumber, utility company or the

selling distributor for specific details.

To comply with the National Electrical Code (NFPA

70) and provide additional protection from risk of

electric shock, these pressure washer are equipped

with a UL approved ground fault circuit interrupter

(GFCI) power cord.

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

CAUTION

RISK OF EXPLOSION:

DO NOT USE WITH

FLAMMABLE LIQUIDS.

KEEP WATER SPRAY

AWAY FROM

ELECTRICAL WIRING.

RISK OF INJECTION

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.

USE PROTECTIVE

EYEWEAR WHEN

OPERATING.

97-6419 • HOTSY 1700 • REV. 11/06

5

PRESSURE WASHER OPERATOR’S MANUAL