97-6642 • HOTSY 781SS, 871SS, 921SS • REV. 7/06

OPERATOR’S MANUAL PRESSURE WASHER

10

OPERATION INSTRUCTIONS

Before Starting

1. Read all manuals provided with this pressure wash-

er. Become familiar with location and function of all

operating and safety controls.

WARNING: Check hoses, fittings, wand, trigger gun

and fuel connections daily for signs of wear, cracks

and looseness, and replace as required.

2. Connect water supply hose to the garden hose con-

nector located on pump. The water faucet and supply

hose must be capable of providing a minimum of 3.5

gallons per minute (GPM).

3. Fill oil burner fuel tank. Use kerosene, #1 grade home

heating oil, #1 or #2 diesel fuel. DO NOT USE GAS-

OLINE, CRANKCASE OIL DRAININGS, ORWASTE

OIL.

WARNING: DO NOT fill engine fuel tank while engine

is running or hot. Let engine cool before refueling or

spontaneous fire may result. Fuel spillage or vapors

could ignite if engine is hot.

4. Fill the engine fuel tank.Do not overfill, fill to the bottom

of filler neck only. Use lead free gasoline minimum 86

octane. DO NOT use gasoline containing more than

15% MTBE, 5% methanol or 10% ethanol. Refer to

the provided gasoline engine manual for additional

details.

5. Check pump and engine oil levels.

6. If detergents are to be used, only use detergents

intended for pressure washers. Follow instructions on

the detergent container.

IMPORTANT: Before installing pressure nozzle on

initial start-up, turn on the water supply and allow

water to run from the end of the wand until clear to

prevent the pressure nozzle from clogging.

IMPORTANT: If the pressure washer has not been

used for an extended period of time, remove the

pressure nozzle from the end of the wand and turn

on water supply. Allow water to run from the end of

the wand until clear.

7. Install the proper pressure nozzle for your cleaning

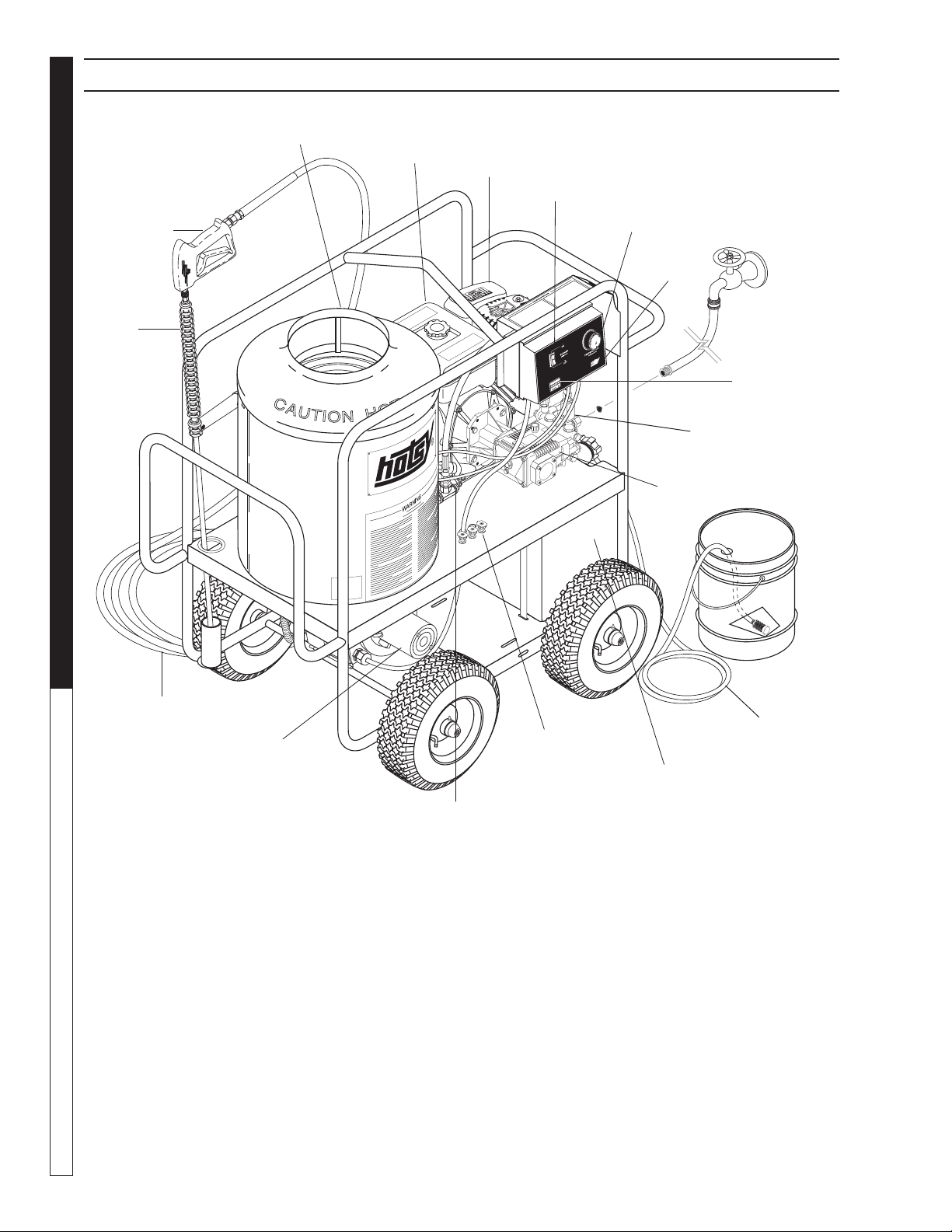

needs on the end of wand, refer to Figure 4.

IMPORTANT:The trigger gun provided with this pres-

sure washer is equipped with a manual trigger lock to

prevent accidental operation of the trigger gun. (Refer

to Figure 4) The manual trigger lock should be used

whenever the trigger gun is not in use.

To Start

DANGER: DO NOT point wand or trigger gun at your-

self or at any person. Bodily injury may result from

water under high pressure.

WARNING: Wear eye, ear, hand, foot and skin protec-

tion at all times while operating pressure washer.

IMPORTANT: The water must be turned on before

starting. Running the pump dry will cause damage

and void warranty.

IMPORTANT: DO NOT allow the machine to run with

trigger of the trigger gun released for more than

10 minutes at any one time or damage to pump may

occur.

1. Turn ON water supply.

2. Hold wand firmly, release trigger of trigger gun.

3. Place engine ON/OFF switch in the ON position.

4. Open fuel shutoff valve (if so equipped). Move choke

lever to FULL CHOKE position, (choke may not be

needed on warm engine). Move throttle lever to HALF

THROTTLE position.

5. Pull the rope starter slowly until resistance is felt, then

pull briskly. Do not allow the rope starter to snap back

against the engine. Return it gently to prevent damage

to the starter.

6. When the engine starts, move choke lever until

engine runs smoothly. When engine warms, move

choke lever to NO CHOKE position. Move throttle

lever to FULL THROTTLE position.

IMPORTANT: To allow for proper burner operation,

the throttle control must be kept in the full throttle

position during operation.

NOTE: If engine fails to start, refer toTroubleshooting

Guide in this manual.

7. Squeeze trigger of trigger gun and allow air to purge

from system.

8. If HOT water is desired, adjust the thermostat to the

proper temperature and turn burner switch ON. The

burner will light immediately with a small puff of smoke.

You may need to initially adjust your burner for peak

performance. See Oil Burner section under Instal-

lation.If smoke continues, contact Customer Service

at 1-303-792-5200. When the trigger of the trigger

gun is released or when the thermostat temperature

setting is reached, the burner will automatically turn

off.

Figure 4 - Nozzle Installation/Manual Trigger Lock

Manual Trigger Lock

Pressure

Nozzle