2 Safety

2.1 Symbols

Caution

This symbol warns against risk of injury. Please heed all instructions desig-

nated by this symbol to prevent injuries and/or death.

Attention

This symbol warns against property damage. Please heed the respective

instructions to prevent risk of damage to the unit and its functions.

Notice

This symbol denotes information about the economic use of the equipment

or special tips.

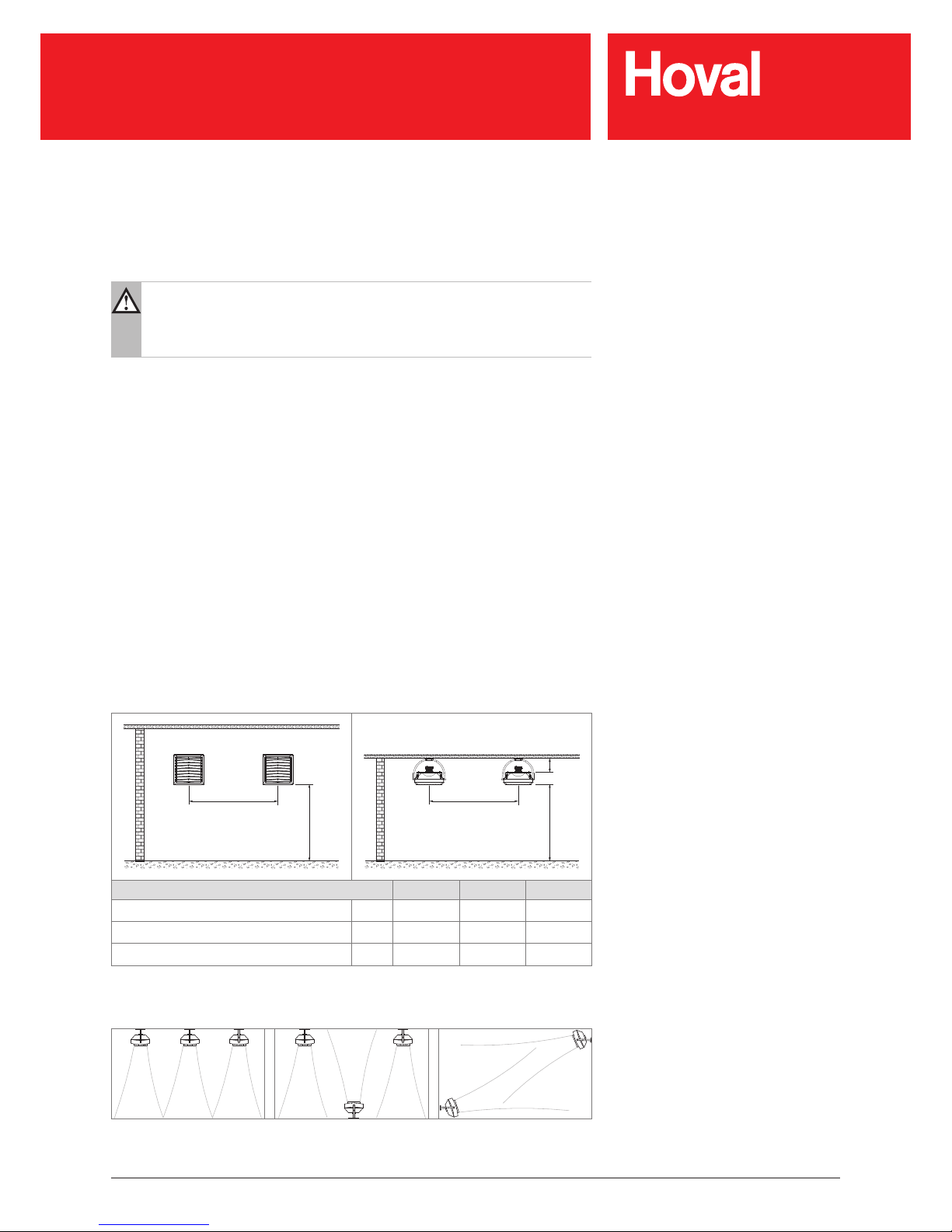

2.2 Operational safety

The unit is built to conform to the state-of-the-art and is operationally safe.

Despite every precaution being taken, potential and not immediately obvious risks

always remain, for example:

■ Dangers when working with the electrical system

■ Parts (e.g. tools) can fall down below when working on the ventilation unit.

■ Malfunctions as a result of defective parts

■ Hazards from hot water when working on the hot water supply

Therefore:

■ Please read the operating instructions before unpacking, installing, commis-

sioning and before maintaining the equipment.

■ Store the operating instructions so that they are easily accessible.

■ Observe any attached information and warning signs.

■ Immediately replace damaged or removed informational and warning signs.

■ Follow the local safety and accident prevention regulations at all times.

■ Disconnect the power supply and wait at least 5 minutes before opening the

unit.

■ When working in the unit, take precautions against unprotected, sharp metal

edges.

■ The unit may only be installed, operated and serviced by authorised, trained

and instructed skilled personnel:

– Specialists as dened by these operating instructions are those persons

who, based on their training, knowledge and experience as well as their

knowledge of the relevant regulations and guidelines, can carry out the work

assigned to them and recognise potential hazards.

■ Unauthorised reconguration or modication of the unit is not permitted.

TopVent®TV

Safety

Art.No. 4 216 284-en-01 / Page 4