98

PRECAUTIONS DURING USAGE

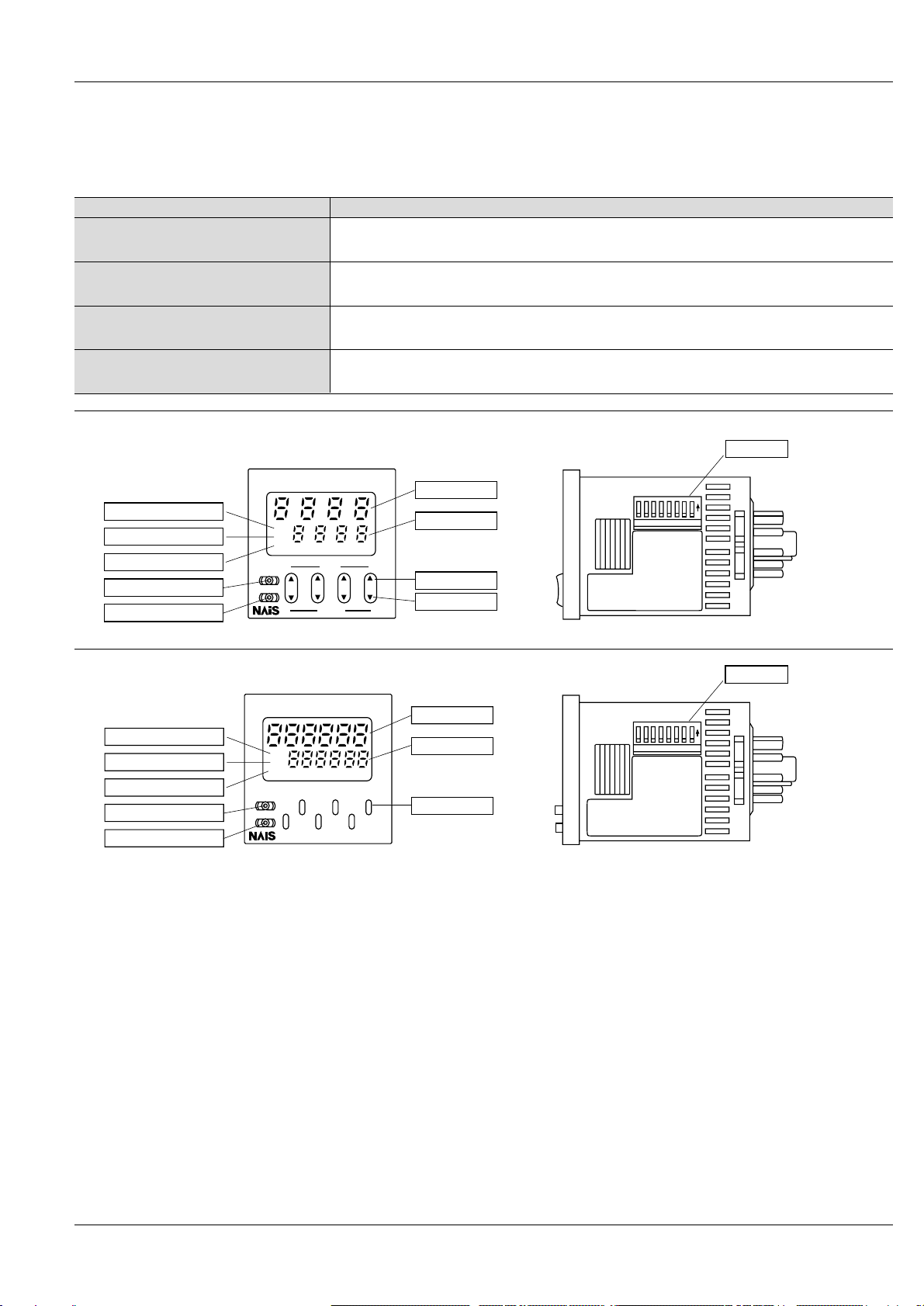

1. Terminal wiring

1) When wiring the terminals, refer to the

terminal layout and wiring diagrams and

be sure to perform the wiring properly

without errors.

2) For embedded installation applica-

tions, the screw-down terminal type is

recommended.

Use either the rear terminal block (A 8-

RR) or the 8P cap (AD8-RC) for the 8-

pin type, and the 11P cap (A 8-DP11)

for the 11-pin type. Avoid soldering

directly to the round pins on the unit.

For front panel installation applications,

use the 11-pin type DIN rail terminal

block (A C18004).

3) After turning the unit off, make sure

that any resulting induced voltage or

residual voltage is not applied to power

supply terminals Wthrough U(8-pin

type), Wthrough P(11-pin type) or

and (screw-down terminal type). (If

the power supply wire is wired parallel to

the high voltage wire or power wire, an

induced voltage may be generated

between the power supply terminals.)

4) Have the power supply voltage pass

through a switch or relay so that it is

applied at one time. If the power supply

is applied gradually, the counting may

malfunction regardless of the settings,

the power supply reset may not function,

or other such unpredictable occurrence

may result.

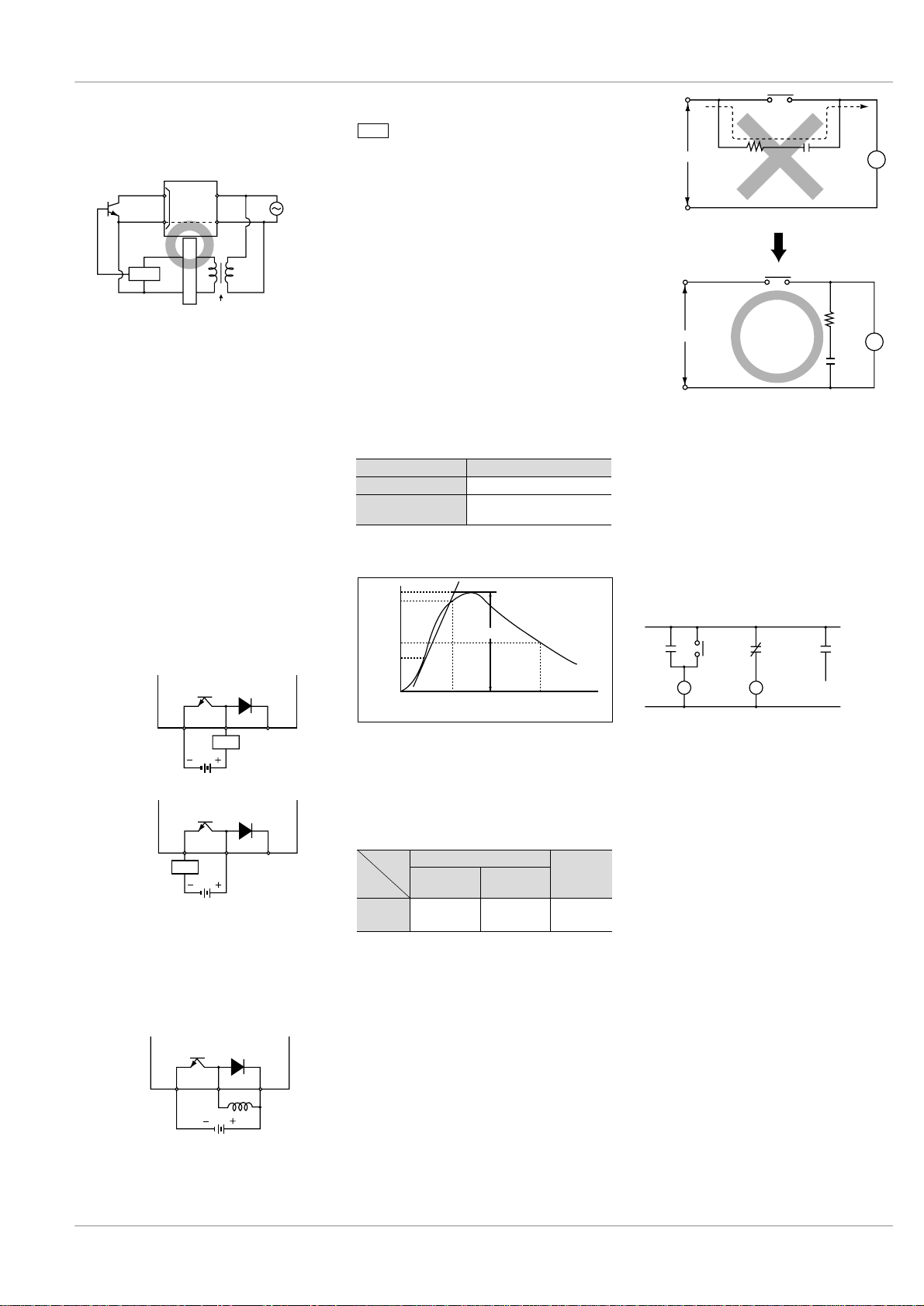

2. Input connections

he power circuit has no transformer.

When an input signal is fed to two or

more counters at once, do not arrange

the power circuit in an independent way.

If the counter is powered on and off inde-

pendently as shown in Fig. A, the coun-

ter's internal circuitry may get

damaged.Be careful never to allow such cir-

cuitry. (Figs. A, B and C show the circuitry for

the 11-pin type.)

21

If independent power circuitry must be used,

keep the input contacts or transistors sepa-

rate from each other, as shown in Fig. B.

When power circuitry is not independent,

one input signal can be fed to two or

more counters at once, as shown in Fig. C.

3. Input and output

1) Signal input type

(1) Contact point input

Use highly reliable metal plated contacts.

Since the contact point’s bounce time

leads directly to error in the count value,

use contacts with as short a bounce time

as possible. In general, select Input 1

and Input 2 to have a maximum counting

speed of 30 Hz and to be reset with a

minimum input signal width of 20 ms.

(2) Non-contact point input

Connect with an open collector. Use

transistors whose characteristics satisfy

the criteria given below.

VCEO = 20 V min.

IC= 20 mA min.

ICBO = 6µA max.

Also, use transistors with a residual volt-

age of less than 2 V when the transistor

is on.

* he short-circuit impedance should be

less than 1 kΩ.

[When the impedance is 0 W, the current

coming from the input 1 and input 2 ter-

minals is approximately 12 mA, and from

the reset input and lock input terminals is

approximately 1.5 mA.]

Also, the open-circuit impedance should

be more than 100 kΩ.

* As shown in the diagram below, from a

non-contact point circuit (proximity

switches, photoelectric switches, etc.)

with a power supply voltage of between

12 and 40 V, the signal can be input

without using an open collector transis-

tor. In the case of the diagram below,

when the non-contact point transistor Q

switches from off to on (when the signal

voltage goes from high to low), the sig-

nal is input.

2) he input mode and output mode

change depending on the DIP switch set-

tings. herefore, before making any con-

nections, be sure to confirm the opera-

tion mode and operation conditions cur-

rently set.

3) For the power supply of the input

Note: he LC4H-W does not have the lock input

R.

7

Note: he LC4H-W does not have the lock input

R.

7