EL-MF877-00 Page 1

Template Revision C

Last revalidation date 04-01-2018

HPI instructions for this template are available at EL-MF877-01

Product End-of-Life Disassembly Instructions

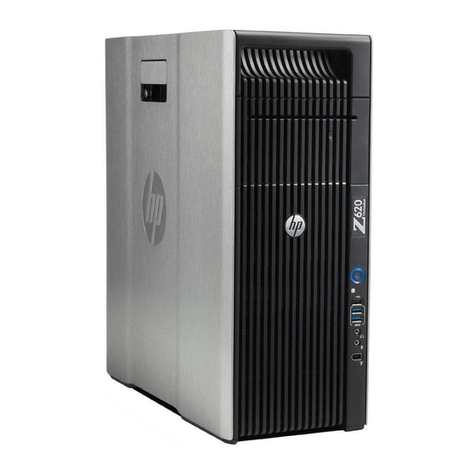

Product Category: Workstations

Marketing Name / Model

[List multiple models if applicable.]

HP Z2 Mini G5 Workstation

Purpose: The document is intended for use by end-of-life recyclers or treatment facilities. It provides the basic instructions for the

disassembly of HPI products to remove components and materials requiring selective treatment, as defined by EU directive

2002/96/EC, Waste Electrical and Electronic Equipment (WEEE).

NOTE: Recyclers should sort plastic materials into resin streams for recycling based on the ISO 11469 plastic marking code on the

plastic part. For any questions on plastic marking, please contact HP’s Sustainability Contact.

1.0 Items Requiring Selective Treatment

1.1 Items listed below are classified as requiring selective treatment.

1.2 Enter the quantity of items contained within the product which require selective treatment in the right column, as applicable.

Item Description Notes

items

included in

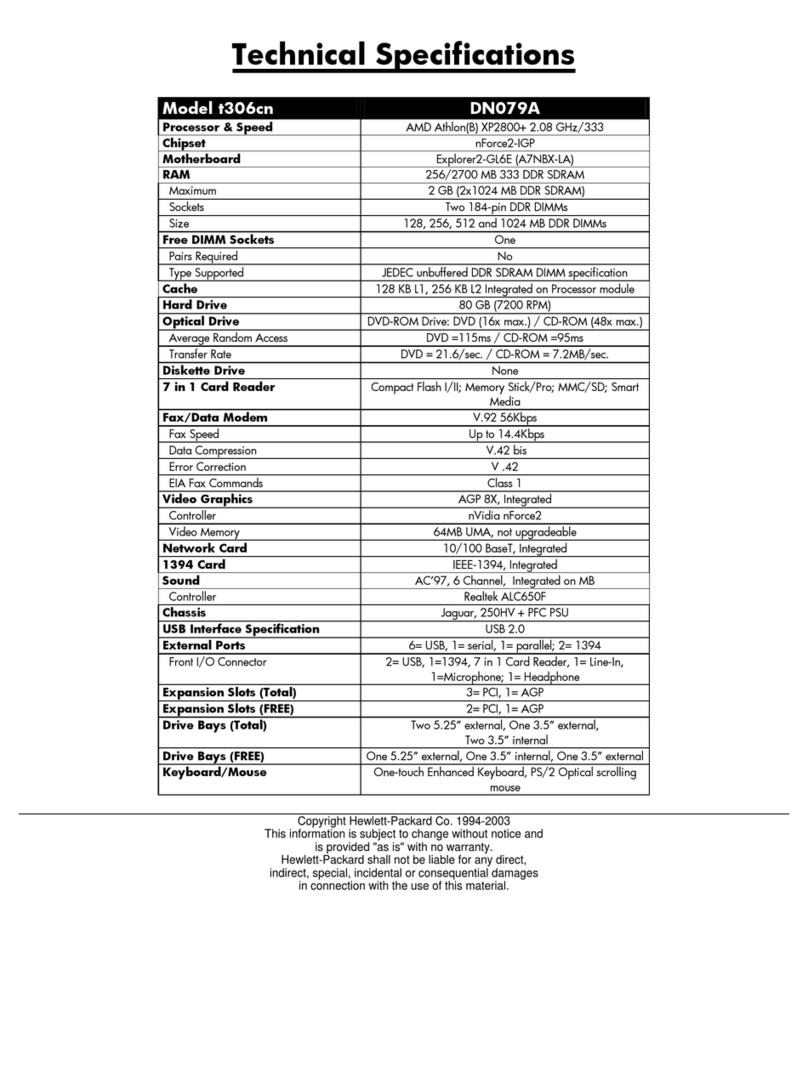

Printed Circuit Boards (PCB) or Printed Circuit

Assemblies (PCA)

With a surface greater than 10 sq cm

Batteries, excluding Li-Ion batteries.

All types including standard alkaline, coin or button style

batteries

Li-Ion batteries. Include all Li-Ion batteries if more than

one is provided with the product (such as a detachable

notebook keyboard battery, RTC coin cell, etc.)

Battery(ies) are attached to the product by (check all

that apply with an “x” inside the “[ ]”):

[0 ] screws

[0 ] snaps

[ ] adhesive

[ ] other. Explain

NOTE: Add detailed removal procedures including

required tools in the sections 3.1/3.2.

Mercury-containing components For example, mercury in lamps, display backlights,

scanner lamps, switches, batteries

0

Liquid Crystal Displays (LCD) with a surface greater than

Includes background illuminated displays with gas

0

Capacitors / condensers (Containing PCB/PCT)

Electrolytic Capacitors / Condensers measuring greater

than 2.5 cm in diameter or height

External electrical cables and cords

DC Cable for External Power Supply