MF877-00 Page 2

Template Revision A

HPE instructions for this template are available at MF877-01

Quantity

of items

included

in product

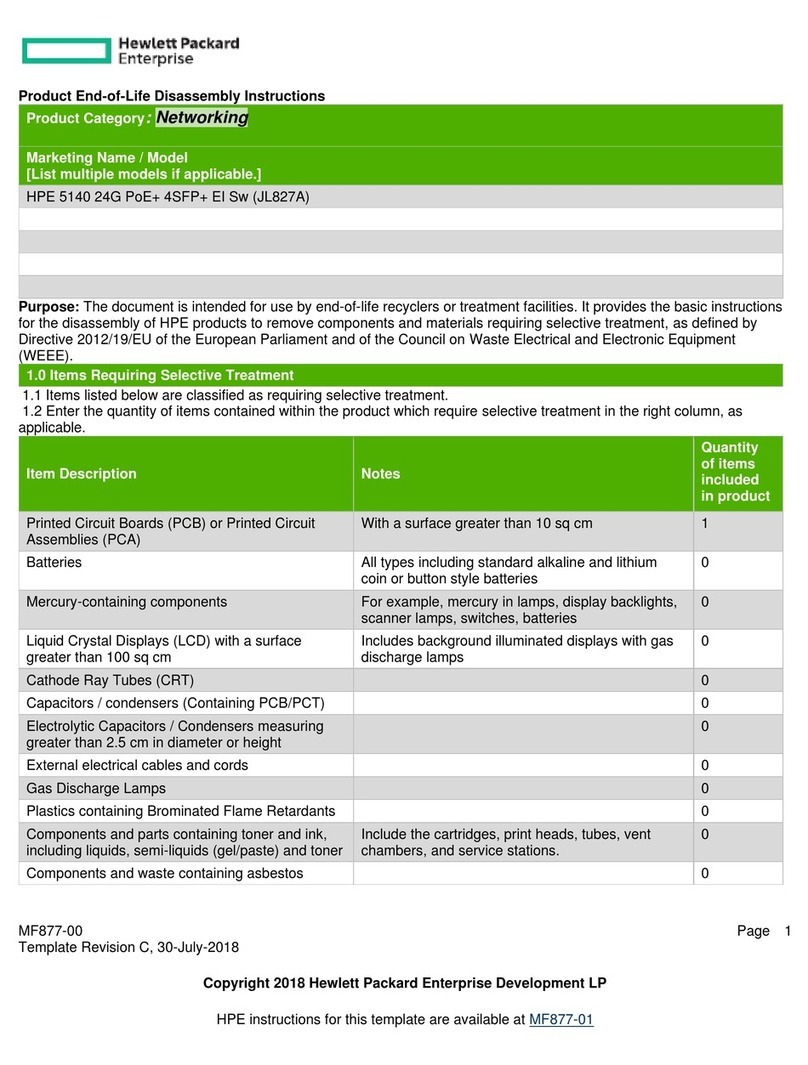

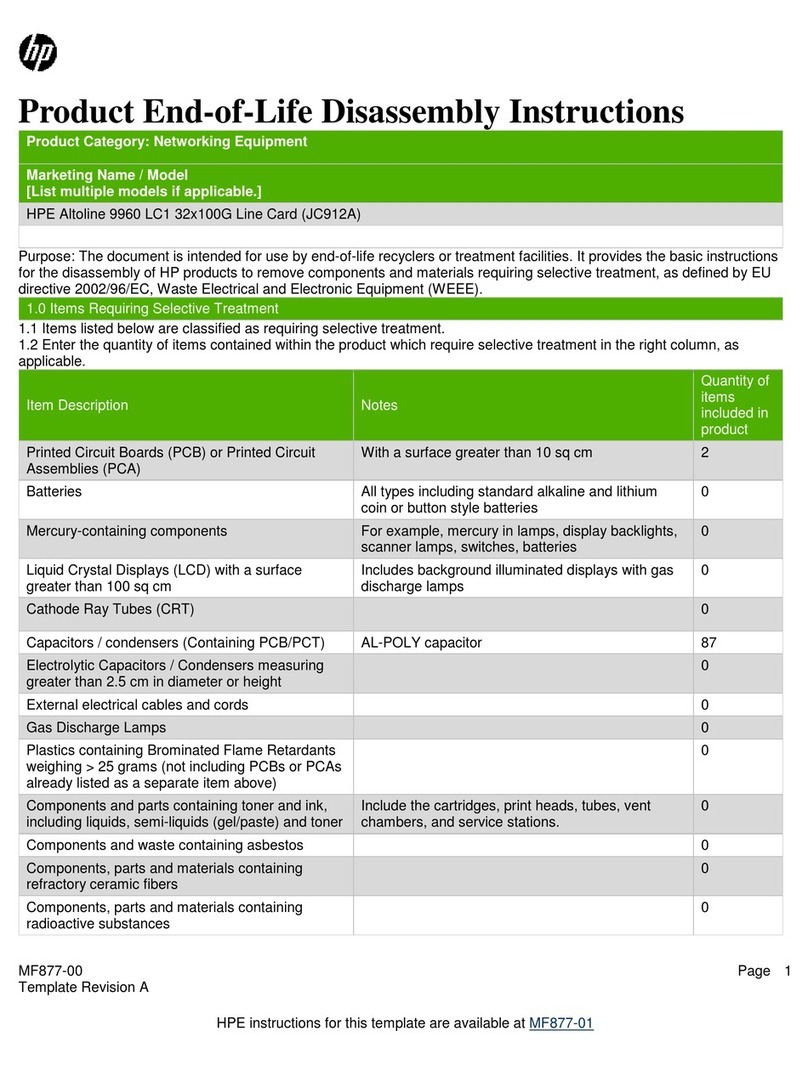

List the type and size of the tools that would typically be used to disassemble the product to a point where components

and materials requiring selective treatment can be removed.

Tool Size (if

applicable)

3.0 Product Disassembly Process

3.1 List the basic steps that should typically be followed to remove components and materials requiring selective treatment:

1. Remove all the blank panel.

2. Remove film 1-1 from panel 1-2.

3. Remove shielding fingers 2-1 from panel 2-2.

4. Unscrew all screws 3, then remove the cover assembly 4 and management panel 5.

5. Remove lab 4-3,4-4,4-5,4-6 and foam 4-2 from cover 4-1.

6. Remove film 5-1 and film 5-3 from panel 5-2.

7. Unscrew all screws 6 and screws 7, then remove the pcb 8,10,11 and air guide 9.

8. Remove dowel 8-1, dowel bushing 8-2, spring 8-3 and radiator 8-4 from pcb 8-5.

9. Unscrew all screws 10-1, then separation of pcb 10-2 and pcb 10-4, then remove the double-screw belts 10-3.

10. Unscrew all screws 11-5, then separation of pcb 11-6 and pcb 11-7, then remove dowel 11-1, dowel bushing 11-2,

spring 11-3 and radiator 11-4 from pcb 11-7.

11. Unscrew all double-screw belts 12 and radiator's screws, then remove radiator 13 and pcb 14.

12. Unscrew all screws 14-1, then remove handle 14-2 from pcb 14-3.

13. Unscrew all screws 15 and screws 17, then remove film 16 and support panel 18.

14. Unscrew all screws 19 and double-screw belts 21, then remove rack 20 and pcb 22.

15. Unscrew all screws 22-1, then remove confluence bar 22-2 from pcb 22-3.

16. Separation of film 23,27, shielding fingers 24, foam 25 and conductive foam 26 from base 28.

3.2 Optional Graphic. If the disassembly process is complex, insert a graphic illustration below to identify the items

contained in the product that require selective treatment (with descriptions and arrows identifying locations).