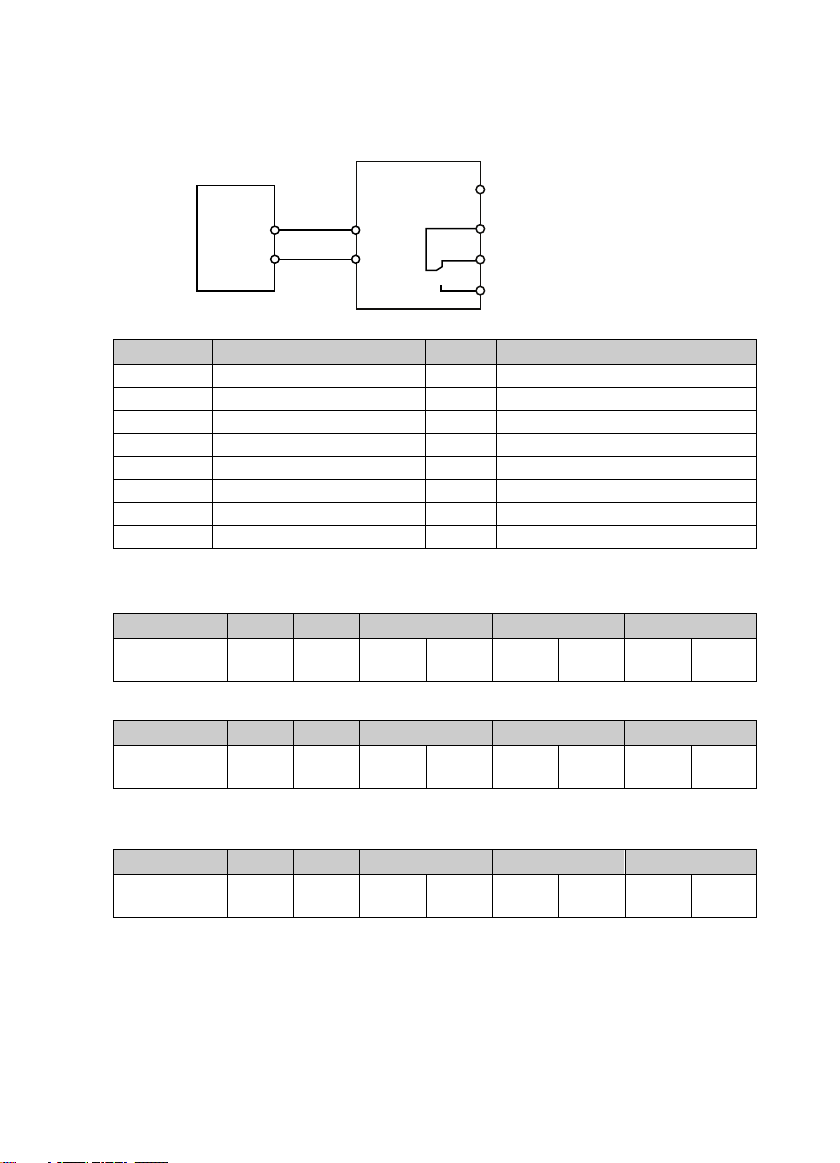

(4). To use terminal to control timing start / stop HD3Z

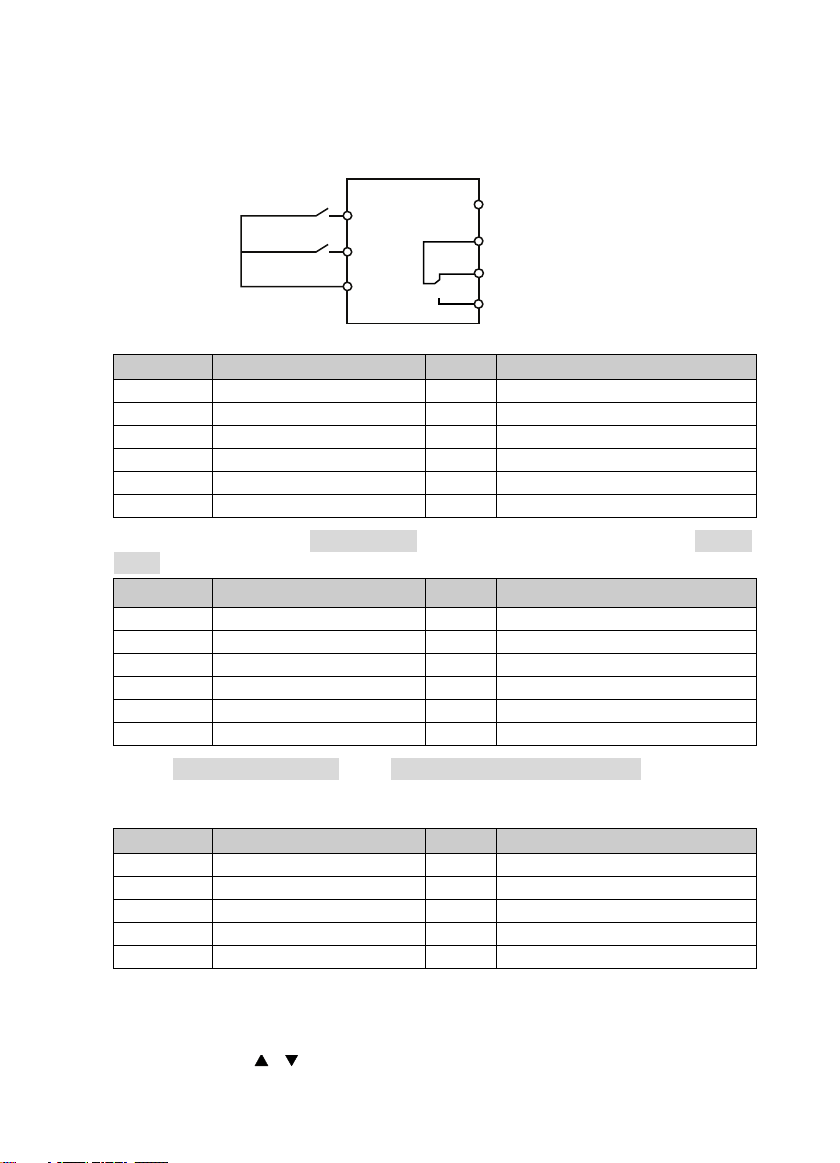

1. Check that HD3Z is installed properly. DI1: Forward signal input; DI2: Reverse signal input. Below is

the connection.

2. Power on, and set function parameters as per below table:

Ref. Code Function Setting Meaning

F00.10 To select frequency setting channel 0 (default) Set by keypad digital setting

F00.11 To select command setting channel 1 Running command set by terminal

F00.13 Running frequency digital setting - Running frequency, set according to actual

F03.01 / F03.02 Acc. / Dec. time 1 - Acc. / Dec. time, adjust according to actual

F15.00 DI1 function selection 2 (default) FWD (DI FWD signal input)

F15.01 DI2 function selection 3 (default) REV (DI REV signal input)

3. Check present time and date (D01.00 - D01.02). If not synchronize with real time, reset time (P00.00 -

P00.02).

Ref. Code Function Setting Meaning

D01.00 Present year - Present year by system

D01.01 Present MM/DD - Present MM/DD by system

D01.02 Present time - Present time by system

P00.00 Year - Set year (according to actual)

P00.01 MM/DD - Set MM/DD (according to actual)

P00.02 Time - Set Hr/Min (according to actual)

4. Enable timing start / stop (P01.00) and set timing start / stop time (P01.01 - P01.08) according to

actual needs. For instance: Set inverter start at 8:00, stop at 12:00, start at 14:00, stop at 17:30.

Refer to below:

Ref. Code Function Setting Meaning

P01.00 Timing start and stop selection 1 Valid, enable timing start and stop

P01.01 Timing start 1 8.00 Start

P01.02 Timing stop 1 12.00 Stop

P01.03 Timing start 2 14.00 Start

P01.04 Timing stop 2 17.30 Stop

5. Connect K1 or K2 to enable timing start or stop function. Inverter will auto controls motor to run

FWD or REV or stop according to time sequence in above table. Disconnect K1 or K2, motor stops

running, inverter exits timing start / stop function.

6. Set F00.13 or press / on keypad to increase / decrease setting frequency.

DI1

COM

K1

K2 DI2

DO1

R1C

R1B

R1A

ForwardOutput indicating

signal at running

Fault indicating

Reverse