Setup Instructions

Placing components with sharp or pointed feet directly on the HRS Isolation Base

may cause nicks, scratches, or gouges in the surface. The use of a protective barrier

between any metal-like feet or sharp objects will prevent damage to the HRS

Isolation Base surface. Protection from sharp objects as described above is

recommended to prevent scratches and maintain the original beauty of the HRS

Isolation Base.

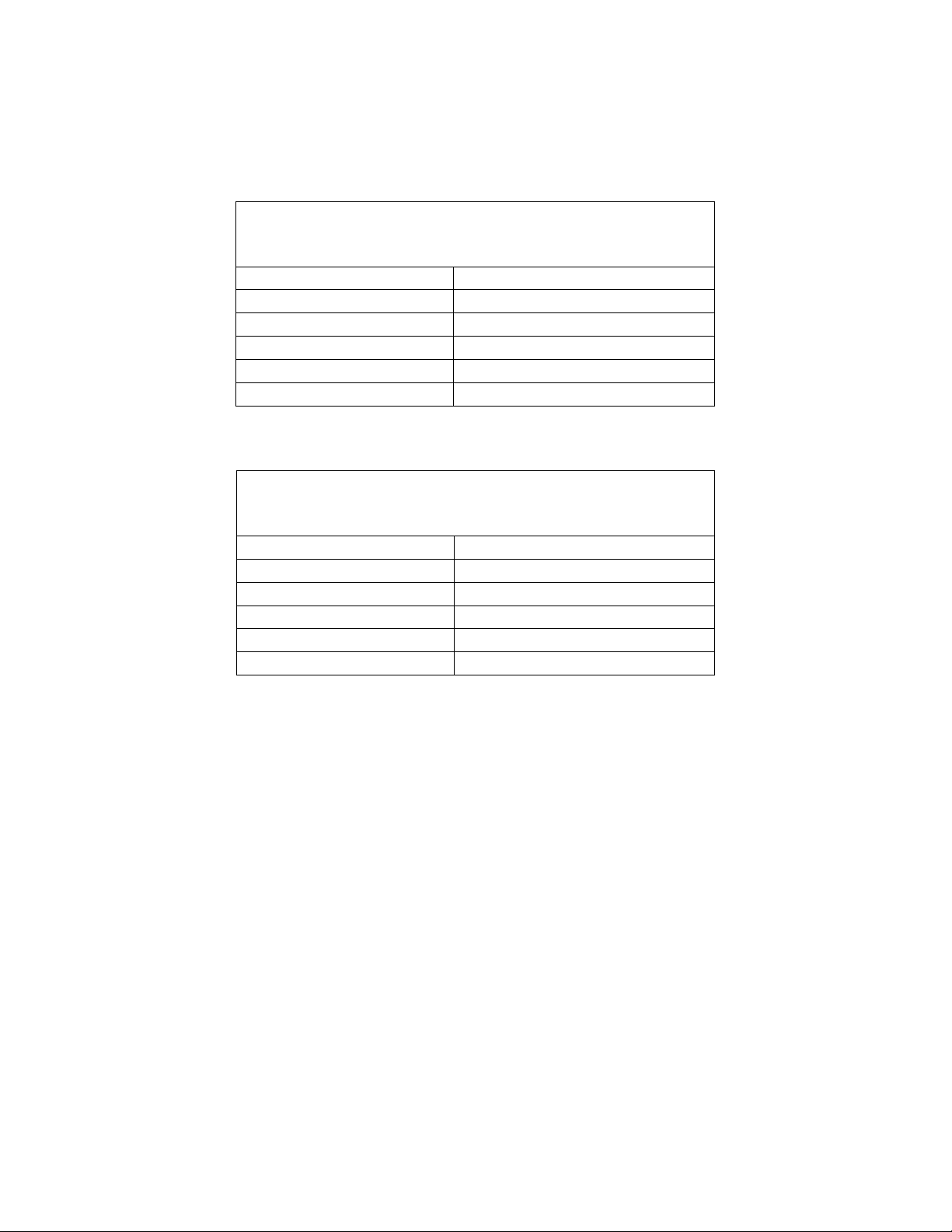

S3 Isolation Bases are produced with different HRS Footer designs to optimize the

performance of specific components. The type of footer the HRS Isolation Base

was originally configured with is identified on a label on the outside of its original

packaging. The footer designation is also identified by a color-coded dot located on

the back edge of the frame. HRS Isolation Bases have a unique ability to be changed

at any time to optimize performance for a different component or different

environment. If you change the feet of the HRS Isolation Base, we recommend you

also change the color-coded dot on the back of the HRS Isolation Base so it is easy

to identify what performance setting the base is currently configured to.

The HRS G7 Bi-Directional Noise Reduction Footer does not have any load range

limit. You can place any component on an S3 Isolation Base configured with G7

Feet. An S3 Isolation Base with G7 Feet is not sensitive to component weight or

weight distribution. HRS Broadband Isolation Feet (SF2 and SF3) and HRS Low

Frequency Feet (LF2 and LF3) are made in various load ranges to optimize

performance for different component weights. When using the SF and LF Footers,

please verify that the component which will be placed on the HRS Isolation Base

is within the rated load range for SF Footer, or is the specific component model

number for LF Footers.

If the SF or LF Footers of the S3 Isolation Base are overloaded, the HRS isolators

will hit a protective stop and significantly reduce the product performance. If your

HRS Isolation Base has SF or LF Feet (pictured on the next page), you can check

to see if the HRS Isolation Base is overloaded by testing for compliance between

the HRS Isolation Base frame and the feet at each corner. With the component

loaded on the HRS Isolation Base, check each corner individually by pressing down

firmly on each corner. An HRS Isolation Base with SF and LF Feet should be

compliant at each corner location and not feel rigid. If there is displacement at each

corner then the HRS Isolation Base is working as designed. If there is no

compliance at one or more corners, then the load range should be changed by HRS

to the proper load range. HRS can modify the HRS S3 Isolation Base load range as

many times as needed for a fraction of the original purchase price. Overloading the

HRS Isolation Base for an extended period of time may reduce its service life and

voids the warranty.