TABLE OF CONTENTS

Page Number

1. Introduction.................................................................................2

1.1 Guidelines Objectives..................................................................2

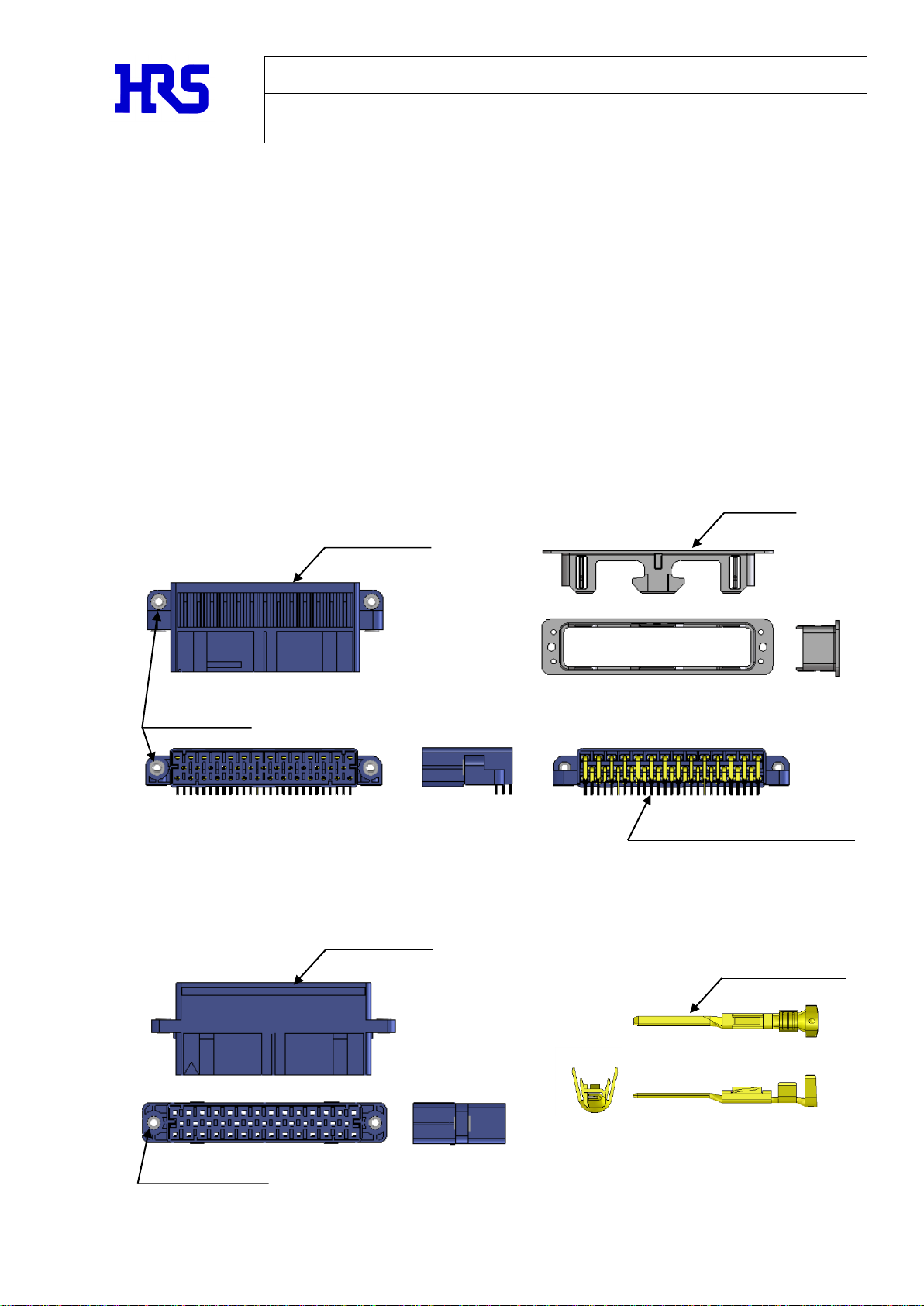

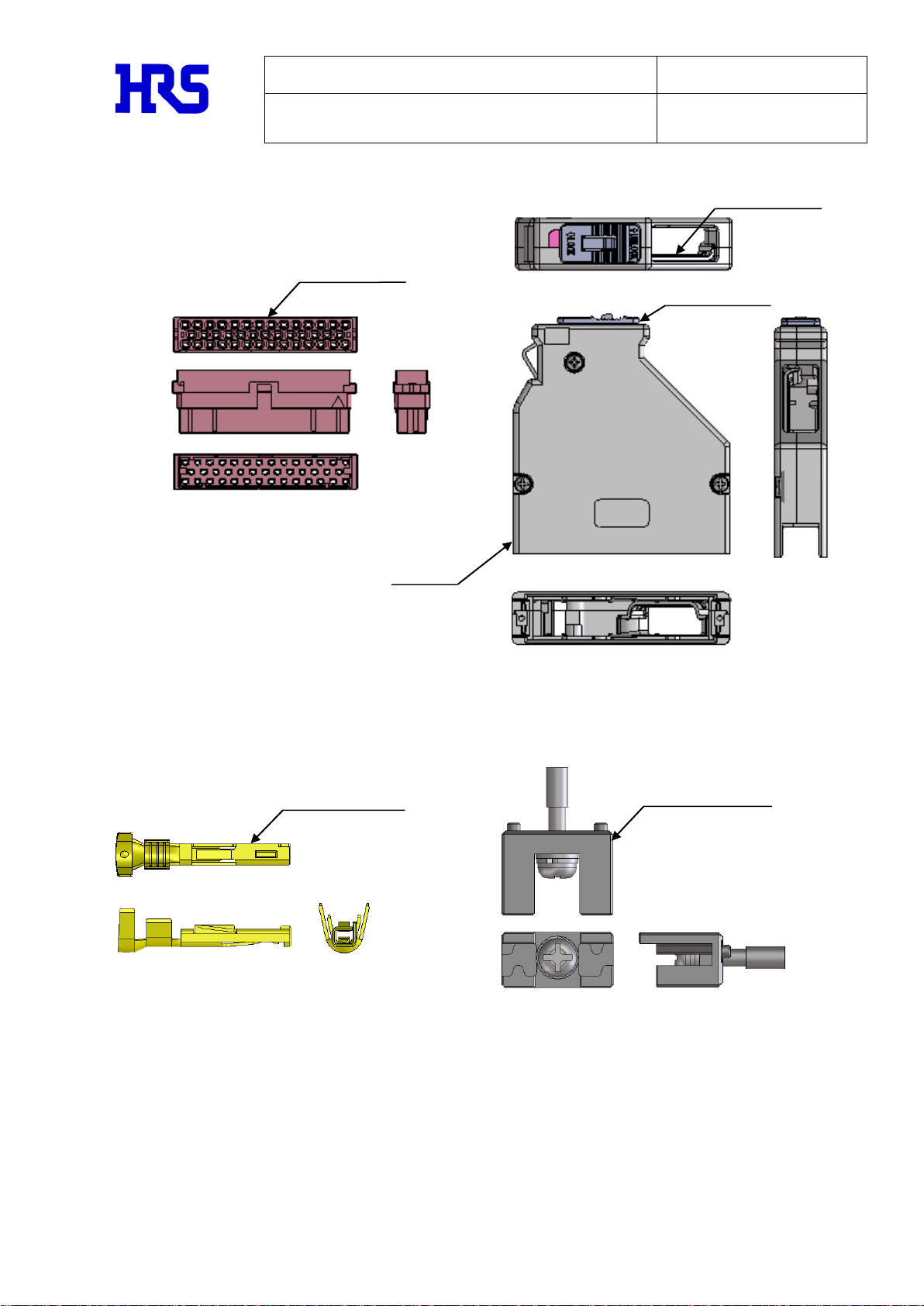

1.2 Names of Connector Components..........................................................2

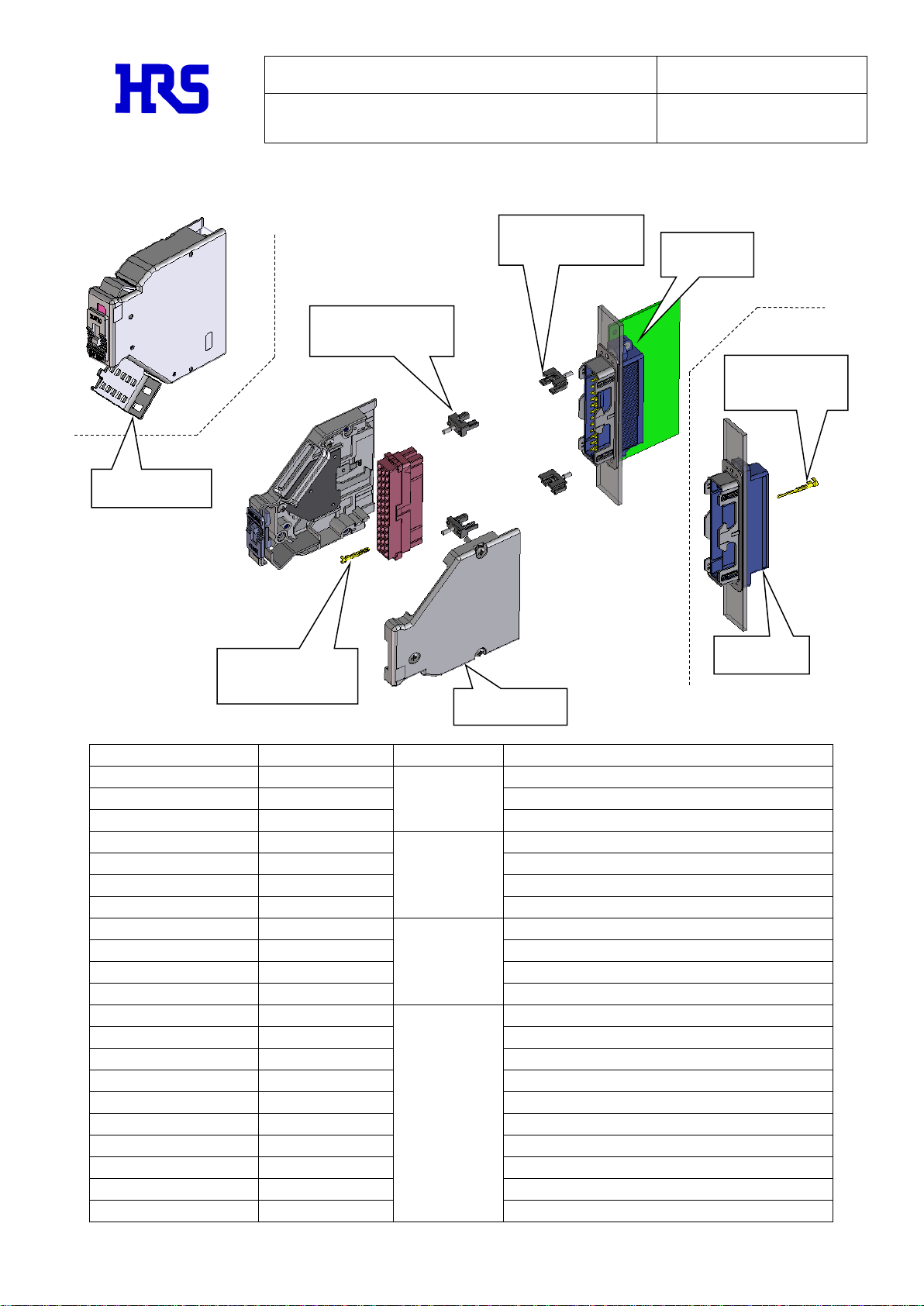

1.3 Product Composition Overview...........................................................4

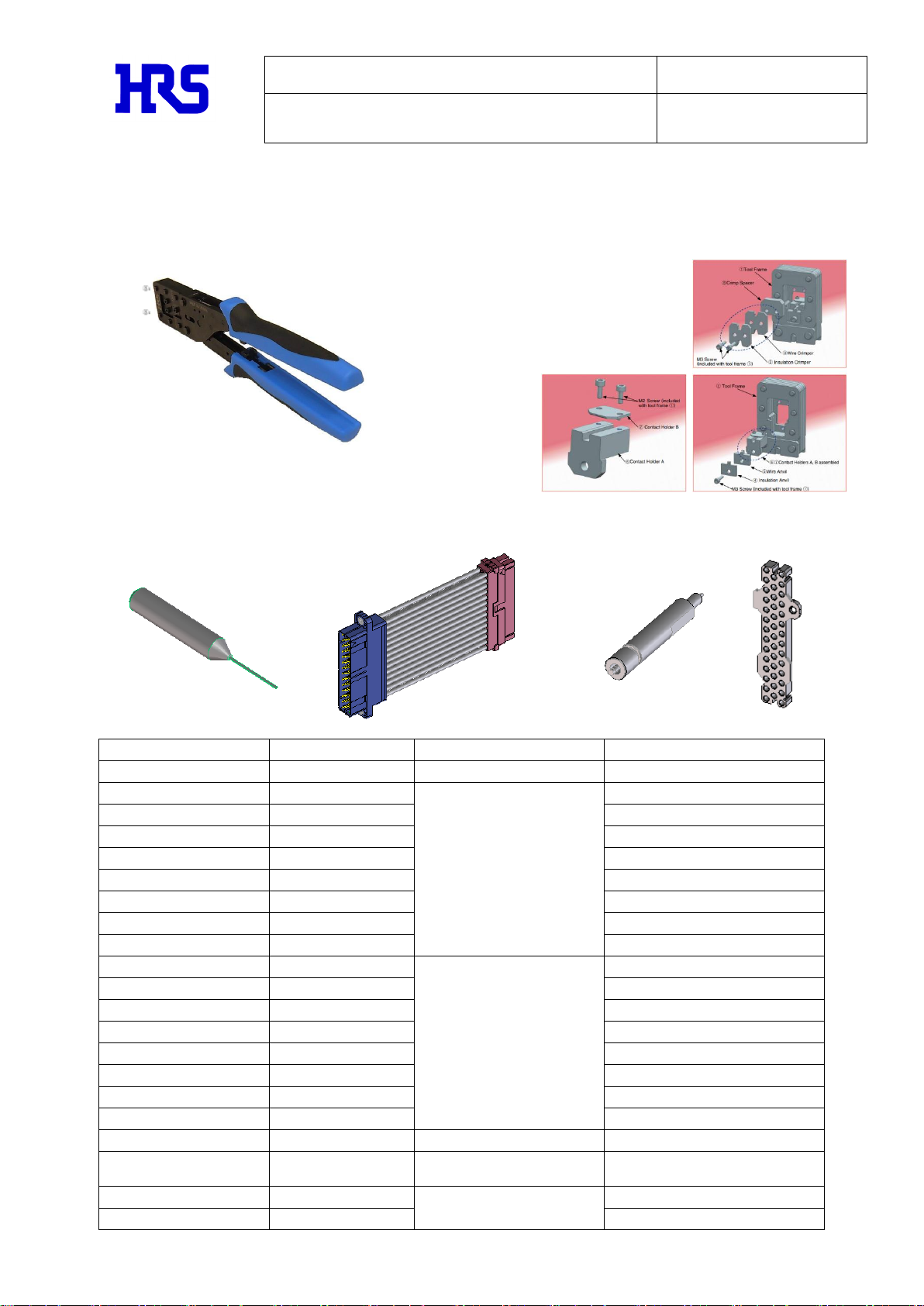

1.4 Tool List..............................................................................5

1.5 Usage Examples.........................................................................6

2. Equipment Design Requirements and Cautions...................................................7

2.1 Receptacle Selection...................................................................7

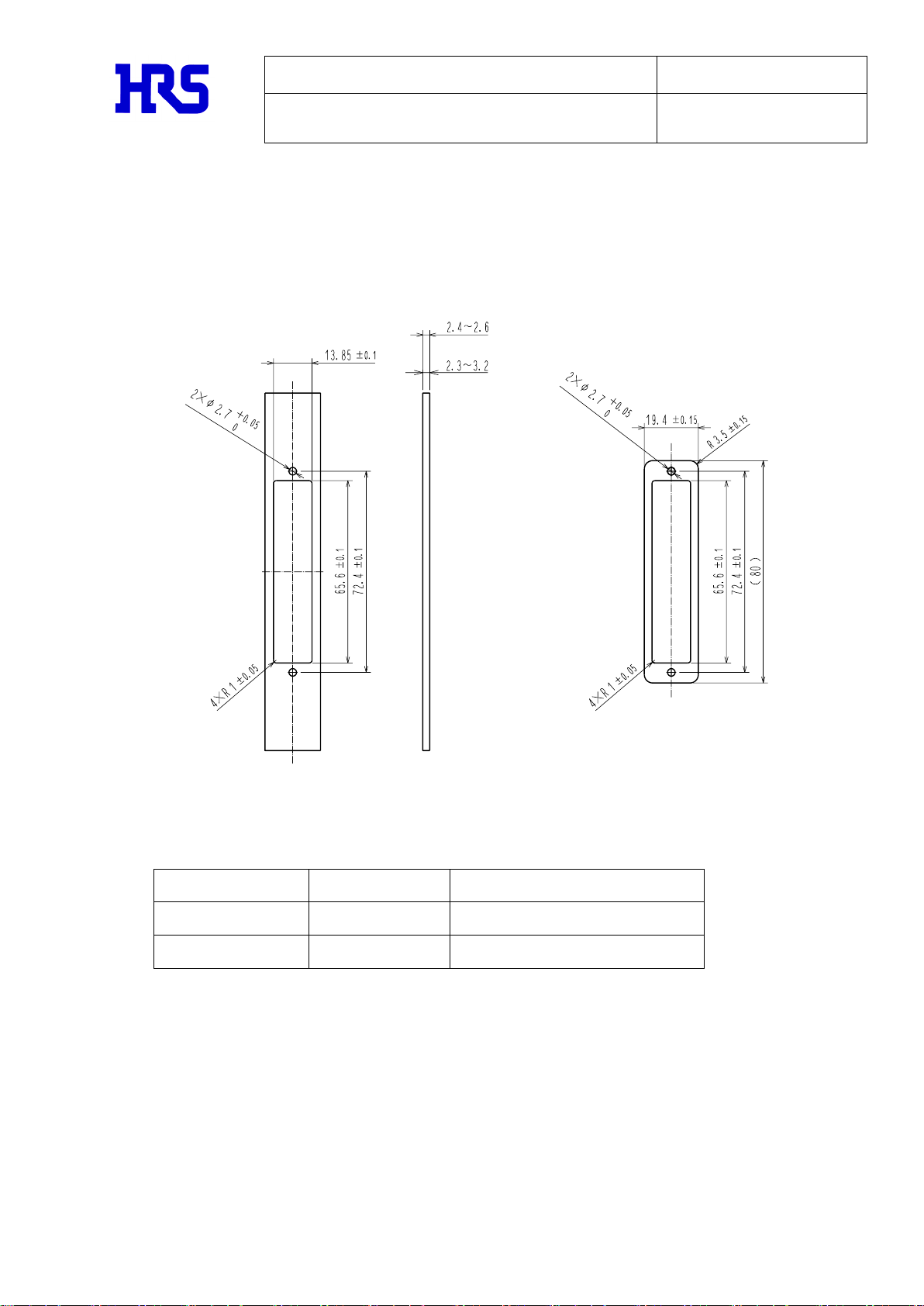

2.2 Panel Cutout ...........................................................................8

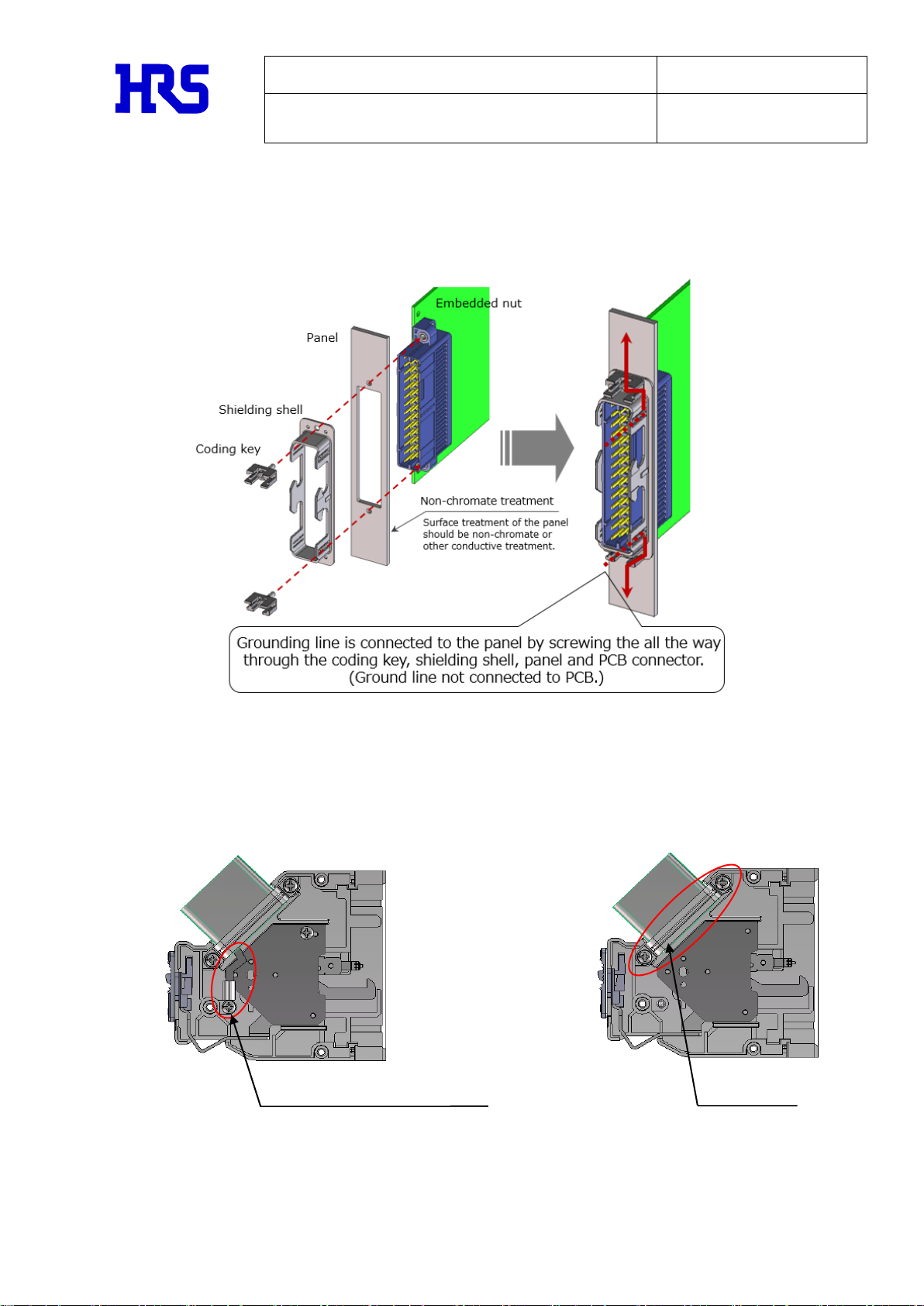

2.3 EMC Prevention .........................................................................9

2.4 Compatible Cables and Crimp contacts ..................................................10

2.5 Plug Selection ........................................................................11

2.6 Misinsertion Prevention Key ...........................................................13

2.7 Temperature Rise Curve ................................................................14

3. Usage Precautions...........................................................................15

3.1 Receptacle Installation Procedure.....................................................15

3.2 Plug Installation Procedure...........................................................17

3.3 Crimp Contact Repair Method...........................................................18

3.4 Cable Clamping Method.................................................................19

3.5 Mating and Locking Method.............................................................20

4. Other Notes .................................................................................21

4.1 Conductivity Confirmation Method ......................................................21

4.2 Contact Assembly Confirmation Method ..................................................22

4.3 Tape for Checking Locking Status ......................................................23

4.4 Connector and Packaging Handling......................................................24

TJA Series Usage Guidelines Revisions Table ................................................. 25

Aug.1.2022Copyright2022HIROSEELECTRICCO.,LTD.AllRightsReserved.