For advice on the safety and suitability of this equipment

contact your local HSS Hire.

There is a serious risk of personal injury if you do not

follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all

necessary risk assessments have been completed prior

to the use of this equipment.

This equipment should only be used by an operator

who has been deemed competent to do so by his/her

employer.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability, should seek expert advice before using it.

Keep children, animals and bystanders away from the

work area. Cordon off a NO GO area using cones and

either barriers or tape, available for hire from your local

HSS Hire.

Never use this equipment if you are ill, feeling

tired, or under the influence of alcohol or drugs.

Wear practical, protective clothing, gloves and

footwear. Avoid loose garments and jewellery

that could catch in moving parts, tie back long hair.

This equipment generates potentially harmful

noise levels. To comply with Health & Safety at Work

regulations, ear defenders must be worn by everyone in

the vicinity.

Safety goggles MUST be worn by everyone in the

work area while the equipment is in use.

Some materials when broken contain substances

which, when inhaled, can be harmful to health. A

suitable mask must be worn when using this equipment.

Never use the equipment near combustible materials or

in potentially explosive atmospheres.

Keep the electric motor’s air-vents clear at all times.

Make sure you know how to switch this machine OFF

before you switch it ON, in case you get into difficulty.

Always switch off and unplug the equipment before

changing steels. Never leave it switched on and

unattended.

Always hold the power tool securely with both hands on

the grips provided. Keep the grips dry, clean and free from

oil and grease.

Take special care when breaking anything containing

pipework or electrical cables. If in doubt, hire a cable

avoiding tool to determine the exact position of such

hazards.

Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

If working above ground-level, always work from a

suitably stable work-platform, such as an access tower.

Do not work from ladders or steps.

The power tool must be used only in a dry environment.

Do not try to repair or modify the equipment. If this tool

can’t do what you expect or fails to work return to HSS Hire.

GENERAL SAFETY

IDENTIFIER

GETTING STARTED

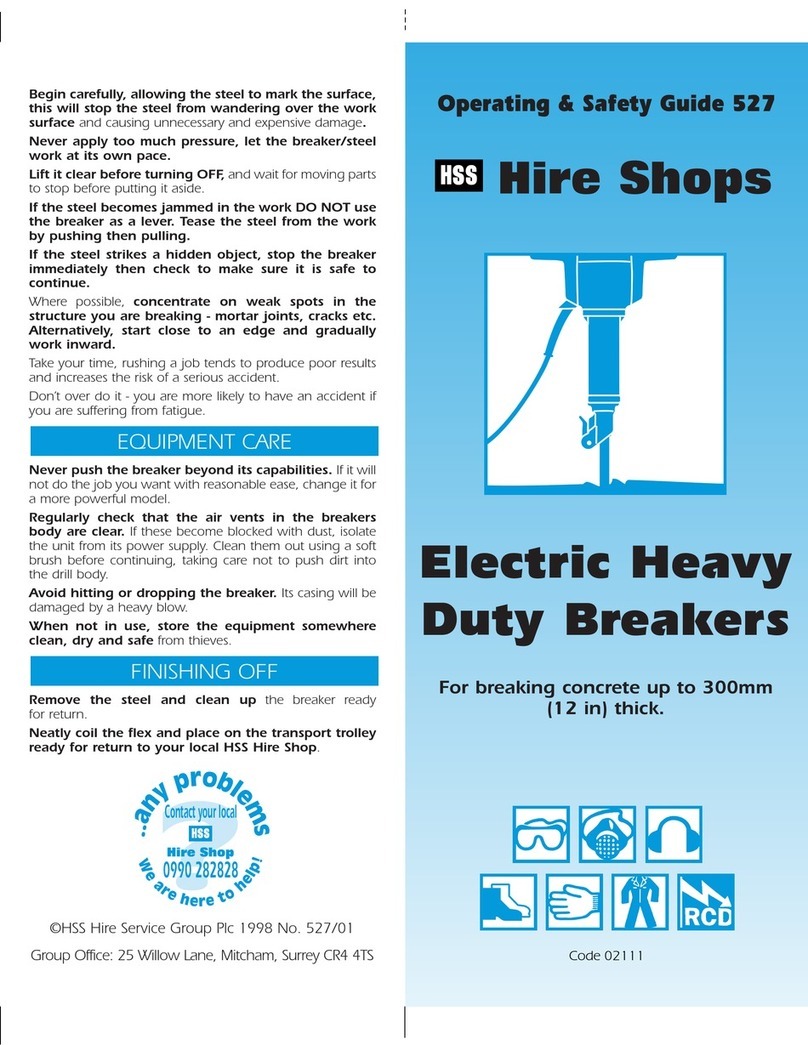

Chuck and chisel

position

adjustment

BASIC TECHNIQUES

Never use the power tool until you have fully read and

understood this User Guide and the equipment has

been properly set up using the information it contains.

The power tool is an electrically-powered breaker with

electropneumatic hammering mechanism designed for

heavy chiseling work. The power tool is designed for

breaking / removing and demolishing concrete, masonry,

stone or asphalt. Working on materials hazardous to the

health (e.g. asbestos) is not permissible.

SETTING SIDE-HANDLE

Set the side-handle to a comfortable working position.

Release the side handle clamping band by turning the

knob. Relax the tension on the side handle clamping ring

and slide it over the chuck and onto the cylindrical section

at the front end of the power tool. Pivot the side handle into

the desired position. Secure the side handle by tightening

the knob.

FITTING STEEL

The chisel can be adjusted to 6 different positions (in 60°

increments). This ensures that flat chisels and shaped

chisels can always be set to the optimum working position.

Before inserting chisel check that the connection end is

clean and lightly greased. Clean it and grease it if necessary.

Push the insert tool into the chuck and rotate it while

applying slight pressure until it engages in the guide grooves.

Push the insert tool further into the chuck until it is heard to

engage.

Check that the insert tool has engaged correctly by pulling it.

SWITCHING ON

To switch on the power tool plug the supply cord into the

power outlet and press the ON / OFF switch.

WORKING AT LOW TEMPERATURES

The unit must reach a minimum operating temperature

before the hammering mechanism begins to operate.

Bring the power tool to the minimum operating

temperature by switching it on and allowing it to run and

warm up. Bring the tip of the chisel into contact with the

work surface at regular intervals (approx. every 30 sec.) to

check whether the hammering mechanism has begun to

operate. Repeat the procedure if the hammering

mechanism does not begin to operate.

NOTE: As starting is electronically controlled, the

power tool’s starting characteristics may be different

in cold conditions.

ELECTRICAL SAFETY

This power tool is designed to plug in to 110V power

socket, so it must be provided with a suitable 110V

generated power supply, or powered from the mains via a

suitable 110V transformer.

When necessary use only extension cords of a type

approved for the application and with conductors of

adequate cross section. The power tool may otherwise

lose performance and the extension cord may overheat.

Check the extension cord at regular intervals. If shows any

signs of damage replace immediately.

When the equipment needs extension cord it is

recommended to use minimum 2,5 mm2cross section cord

with maximum length of 20m.

When working outdoors, use only extension cords that

are approved and correspondingly marked for this

application.

Extension leads should be fully unwound and loosely

coiled, away from the equipment. Never run them

through water, over sharp edges or where they could trip

someone.

If the equipment fails, or if its flex or plug gets

damaged, return it. Never attempt to repair it yourself.

Keep flexes out of harm’s way and clear of moving parts.

To reduce the risk of electric shock, use a suitable

RCD (Residual Current-Operated Device) available

from your local HSS Hire.

Never carry or pull the tool by its flex.

Ensure the equipment is switched OFF before plugging

it into it’s power supply.

Grip

On / off switch

Supply cord

Power level

selection switch

Side handle

Knob

Ventilation

slots

WARNING

If the power tool starts without pressing the on/off

switch when the supply cord is plugged back in after

unplugging, the unit must be returned to HSS Hire.

Service

indicator

Power level

indicator

Ventilation

slots