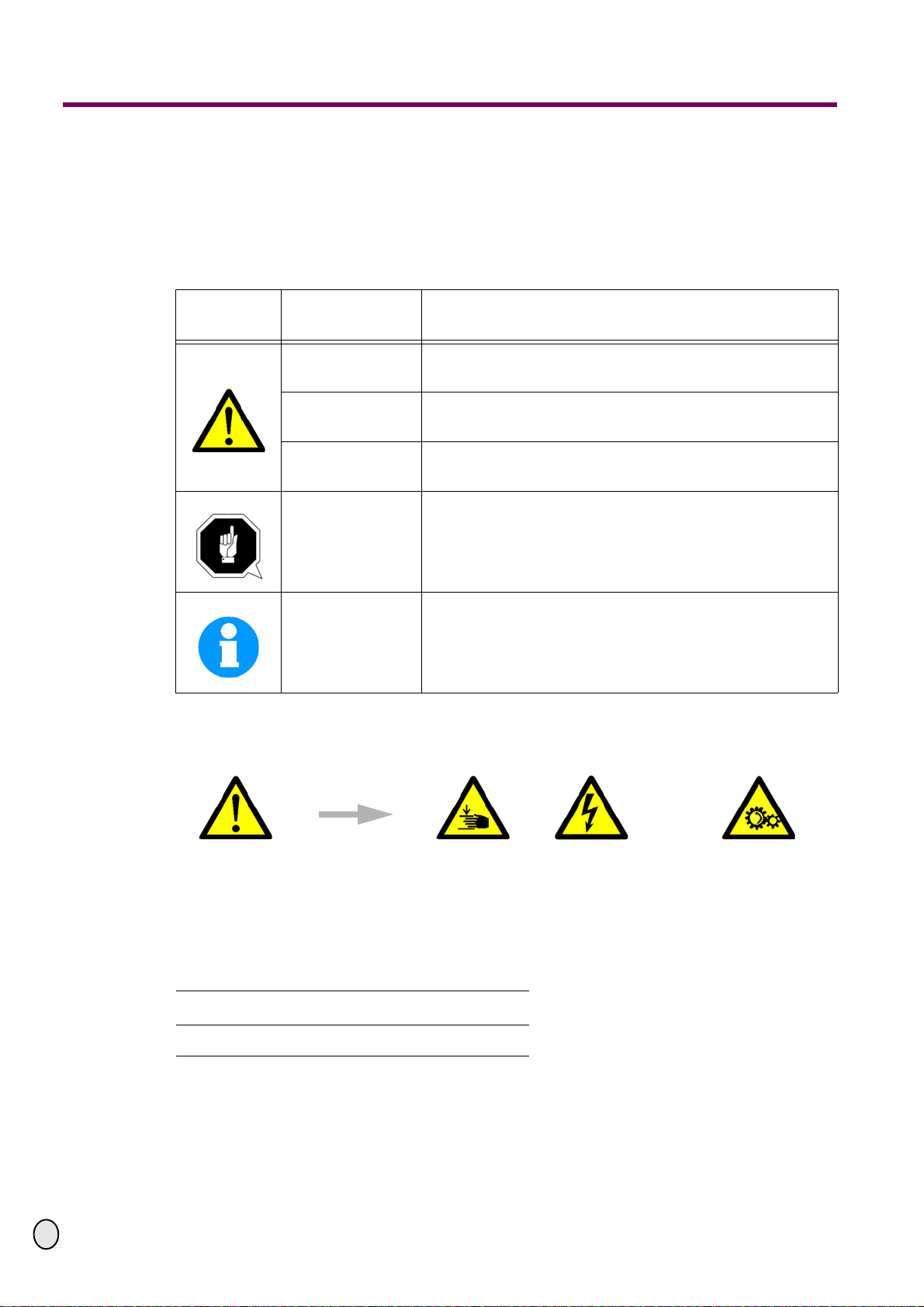

Safety warnings (warning notes)

OPTIMUM

MASCHINEN - GERMANY

23. Oktober 2008Page 4 Safety warnings (warning notes) Add-on kit BF 46 / BF30 Vario CNC ; Version 1.0.2

©2008 GB

1.2 Proper use

WARNING!

In the event of improper use of the add-on pieces, it

• will endanger the user,

• will endanger the machine and other material property of the operator or user,

• may affect proper operation of the machine.

The add-on pieces as conversion kit are provided for motor-driven milling operations of your

machine.

Improper

use! The milling machine with the adapter kit must only be placed and operated in dry and ventilated

rooms.

The handwheels of the driven axes need to be disassembled.

If the adapter kit is used in any way other than described above or modified without approval of

the company Optimum Maschinen Germany GmbH the adapter kit is no longer properly used.

We do not take any liability for damages caused by improper use.

We would like to stress that any modifications to the construction, or technical or technological

modifications that have not been authorized by Optimum Maschinen GmbH will also render the

guarantee null and void.

We are pleased that you have decided to buy a CNC milling machine made by Optimum Maschi-

nen Germany GmbH.

The illustrations of the machines may vary in a few details from the illustrations of this instruction

manual, but this will have no effect on the operation of the machine.

Any changes in the construction, equipment and accessory are reserved for the advancement.

Therefore, you cannot derive any claims from the indications and descriptions. Errors are

reserved!

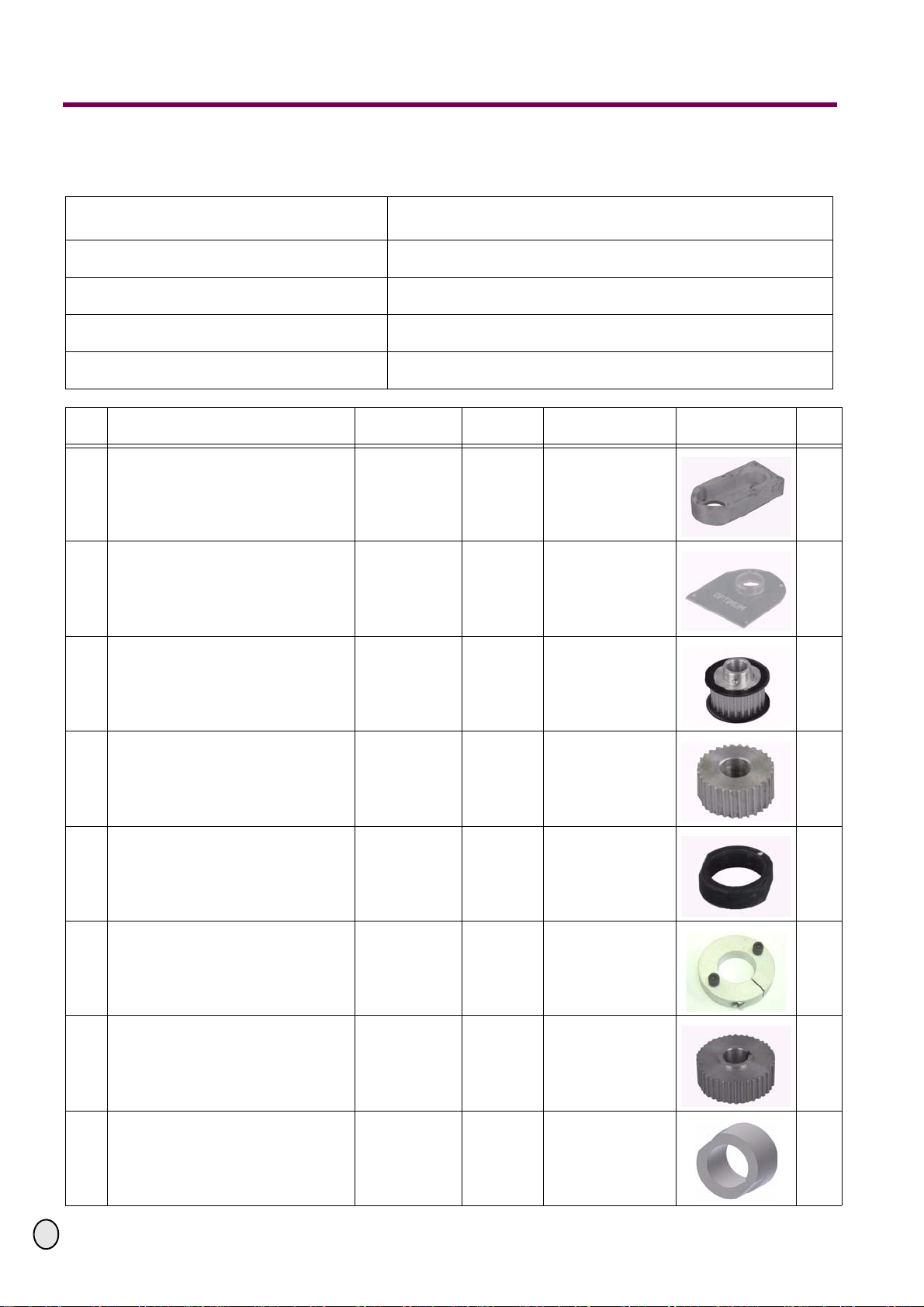

1.3 Required auxiliary material

Means of shaft lock-down device "Loctite 648, join the shaft".

The designation of the parts in the assembly description corresponds to the numbering on

the packing list.

In order to degrease the shaft, a cleaner for brakes or a corresponding cleaning agent is

required.

Required tools:

Hand drill, caliper gauge,

Twist drill 6.8mm, screw tap M8, countersink

Allen key, fork wrench, socket wrench 24mm

Screw driver, tongs

Wire cutter, trimming knife

Hot-air drier, shrink hose, sleeves

Blow-back proof plastic tip hammer

Lubricating oil for thread cutting