! !

Safety Instructions

General safety precautions

• Do not use the machine without first

reading and understanding the contents

of this Operator’s Manual.

WARNING! This section describes basic

safety directions for using the machine.

This information is never a substitute for

professional skills and experience. If

you get into a situation where you feel

unsafe, stop and seek expert advice.

Contact your dealer, service agent or an

experienced user. Do not attempt any

task that you feel unsure of!

Work area safety

• Do not use the machine in inclement

weather, such as dense fog, rain, strong

wind, intense cold, etc.

• Keep the work area clean and well lit.

The machine should not be used in

areas where potential for fire or

explosions exist.

Electrical Safety

WARNING! There is always a risk of

shock from electrically powered

machines. Avoid unfavorable weather

conditions and body contact with

lightning conductors and metal objects.

Always follow the instructions in the

Operator’s Manual to avoid damage.

• Never pull the machine by the cord and

never pull out the plug by pulling the cord.

• Keep all cables away from water, oil and

sharp edges. Make sure the cable is not

pinched. Damaged electrical insulation

can create a shock hazard.

• Check to ensure the cords are in good

condition. Use a heavy duty electrical

cord 12 gauge or greater.

• Never use the machine if any cord is

damaged. Damaged electrical cords

should be destroyed or repaired by an

authorized electrical repair shop.

• The machine should be connected to a

grounded outlet socket.

• Ensure that the main voltage corresponds

with that stated one electrical rating on

the machine. Be on your guard for

electrical shocks.

To avoid overheating, do not use an

extension cord. Use only a 12-gauge

(minimum) cord.

Ensure the cord remains out of the grinding area

to avoid damage

Personal Safety

WARNING! Over exposure to vibration

can lead to circulatory damage or nerve

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure to

vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin color condition. These symptoms

normally appear in the fingers, hands, or

wrist. These symptoms may be

increased in cold temperatures.

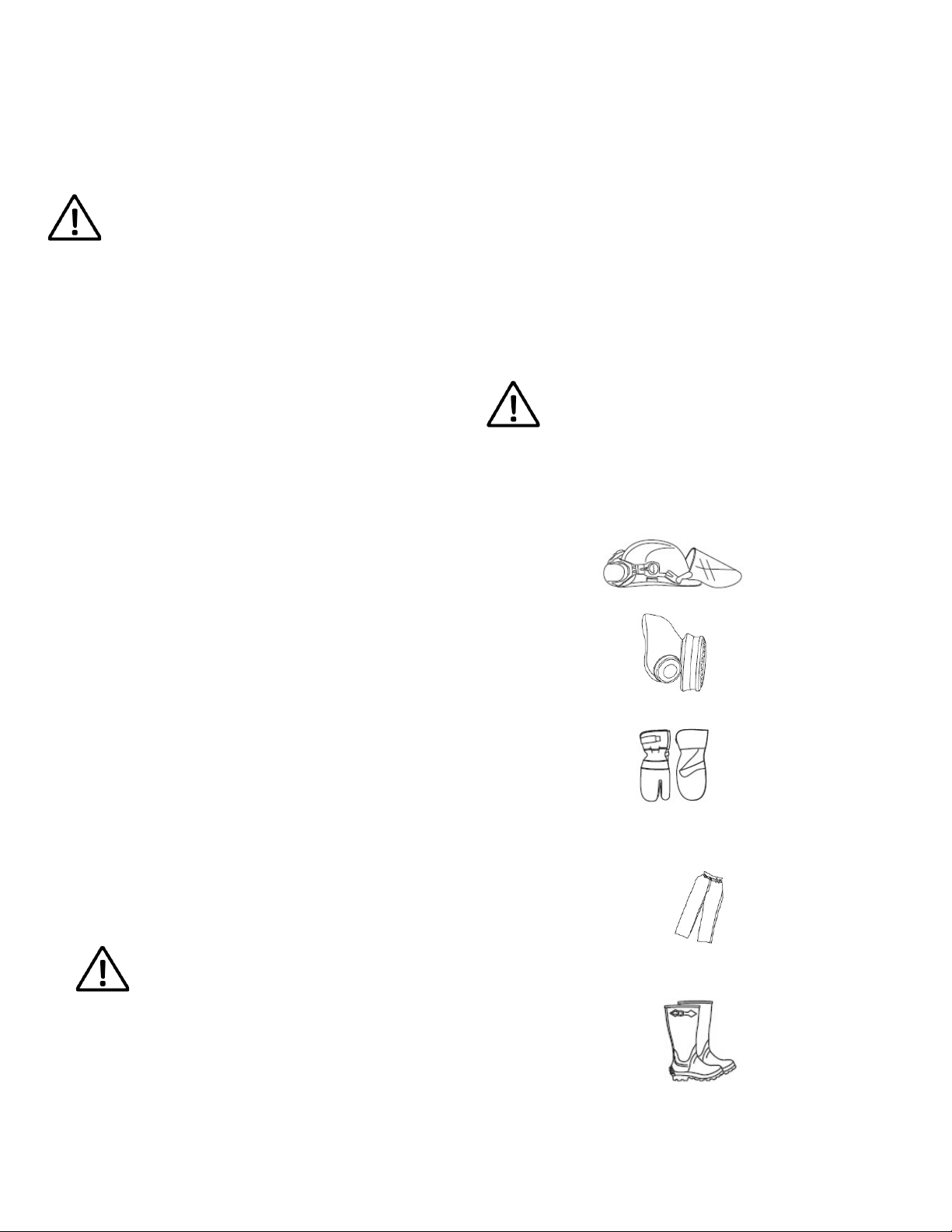

• Wear personal protective equipment. See

instructions under the heading “Personal

protective equipment”.

• Never use the machine if you are tired, or

under the influence of drugs, alcohol, or if

you are taking medication that could

cause impairment.

• All operators shall be trained in the use of

the machine. The owner is responsible for

ensuring that the operators receive

training.

• People and animals can distract you

causing you to lose control of the

machine. Always remain focused on the

task.

• Clothing, long hair, and jewelry can get

caught in moving parts.

• Never leave the machine unsupervised

with the motor running.

• Make sure that there is always another

person close at hand when you use the

machine, so that you can call for help

should an accident occur.

• Always ensure you have a safe and

stable working position