operation.

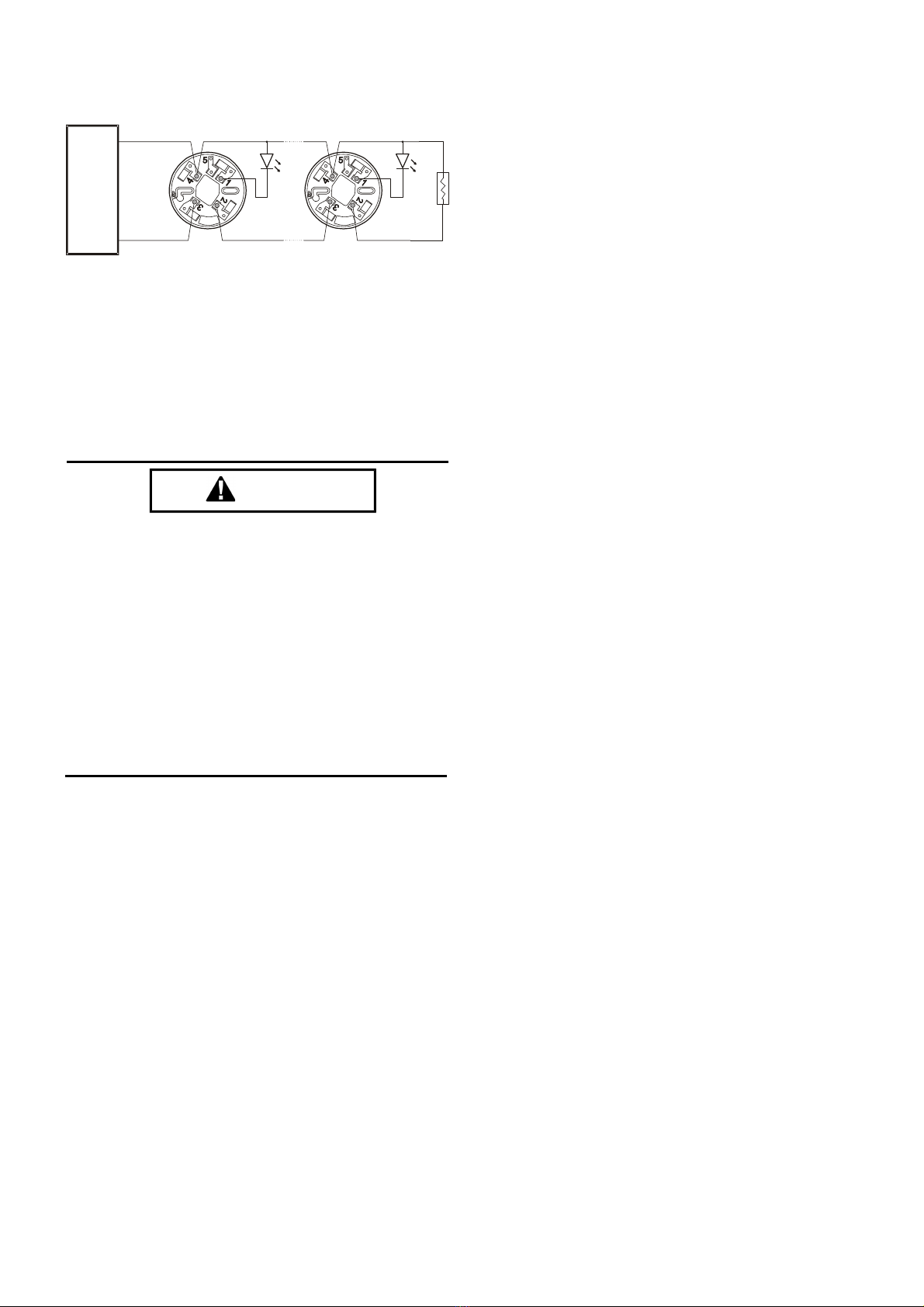

Figure 1. Wiring diagram:

Warning :Forbid connect 4VDC directly without current-limiting

resistance. Otherwise, the detector would be burnt out.

Dust covers are an effective way to imit the entry of

dust into smoke detector sensing chambers. However,

they may not comp ete y prevent airborne dust

partic es from entering the detector. Therefore, We

recommends the remova of detectors before

beginning construction or other dust producing

activity.

Be sure to remove the dust covers from any sensors

that were eft in p ace during construction as part of

returning the system to service.

TAMPER-RESISTANCE

Models DG311 include a tamper-resistant capability that

prevents their removal from the bracket without the use

of a tool.

TESTING

Before testing, notify the proper authorities that the

smoke detector system is undergoing maintenance and

will temporarily be out of service. Disable the zone or

system undergoing maintenance to prevent unwanted

alarms. Detectors must be tested after installation and as

part of periodic maintenance.

NOTE: Before testing the detector, check to ensure the

LEDs blink. If they do not, the detector has lost power

(check the wiring), it is defective (return it for repair), or

the detector sensitivity is outside the listed limits.

The sensor can be tested in the following ways:

A. Smoke Entry test: Aerosol Generator (Gemini 501)

The GEMINI model 501 aerosol generator can be used

for smoke entry testing. Set the generator to represent

4%/ft to 5%/ft obscuration as described in the GEMINI

501 manual. Using the bowl shaped applicator, apply

aerosol until the panel alarms.

B.Direct Heat Method (Hair dryer of 1000 – 1500 watts)

1. From the side of the detector, direct the heat toward the

sensor. Hold the heat source about 6 inches (15cm) away

to prevent damage to the cover during testing.

A sensor that fails any of these tests should be cleaned as

described under CLEANING, and retested. If the sensor

fails after cleaning, it must be replaced.

When testing is complete, restore the system to normal

operation and notify the proper authorities that the system

is back in operation.

CLEANING

Before removing the detector, notify the proper

authorities that the smoke detector system is undergoing

maintenance and will be temporarily out of service.

Disable the zone or system undergoing maintenance to

prevent unwanted alarms.

1. Remove the sensor to be cleaned from the system.

2. Remove the sensor cover by pressing firmly on each

of the four removal tabs that hold the cover in place.

3. Vacuum the screen carefully without removing it. If

further cleaning is required continue with Step 4,

otherwise skip to Step 7.

4. Remove the chamber cover/screen assembly by

pulling it straight out.

5. Use a vacuum cleaner or compressed air to remove

dust and debris from the sensing chamber.

6. Reinstall the chamber cover/screen assembly by

sliding the edge over the sensing chamber. Turn until

it is firmly in place.

7. Replace the cover using the LEDs to align the cover

and then gently pushing it until it locks into place.

8. Reinstall the detector.

9. Test the detector as described in TESTING.

10. Reconnect disabled circuits.

11. Notify the proper authorities that the system is back

on line.