Before testing, notify the proper authorities that the

system is undergoing maintenance, and will temporarily

be out of service. Disable the system to prevent unwanted

All sensors must be tested after installation and

periodically thereafter. Testing methods must satisfy the

Authority Having Jurisdiction (AHJ). Sensors offer

maximum performance when tested and maintained in

The sensor can be tested in the following ways:

A. Smoke Entry test: Aerosol Generator (Gemini 501)

The GEMINI model 501 aerosol generator can be used

for smoke entry testing. Set the generator to represent

4%/ft to 5%/ft obscuration as described in the GEMINI

501 manual. Using the bowl shaped applicator, apply

aerosol until the panel alarms. Additionally, canned

aerosol simulated smoke (canned smoke agent) may be

used for smoke entry testing of the smoke detector. Tested

and approved aerosol smoke products are the Smoke

Detector Tester model 25S available from Home

Safeguard Industries and Chekkit Smoke Detector Tester

models CHEK02 and CHEK06 available from SDi.

When used properly, the canned smoke agent will cause

the smoke detector to go into alarm. Refer to the

manufacturer’s published instructions for proper use of

A.Canned aerosol simulated smoke (canned smoke agent)

formulas will vary by manufacturer. Misuse or overuse of

these products may have long term adverse effects on the

smoke detector. Consult the canned smoke agent

manufacturer’s published instructions for any further

warnings or caution statements.

B. Direct Heat Method (Hair Dryer of 1000-1500 watts)

A hair dryer of 1000-1500 watts should be used to test the

thermistors. Direct the heat toward either of the two

thermistors, holding the heat source approximately 12

inches from the detector in order to avoid damaging the

plastic housing. The detector will reset only after it has

had sufficient time to cool. Make sure both thermistors

A sensor that fails any of these tests should be cleaned as

described under CLEANING, and retested. If the sensor

fails after cleaning, it must be replaced.

When testing is complete, restore the system to normal

operation and notify the proper authorities that the system

Before removing the detector, notify the proper

authorities that the smoke detector system is undergoing

maintenance and will be temporarily out of service.

Disable the zone or system undergoing maintenance to

1. Remove the sensor to be cleaned from the system.

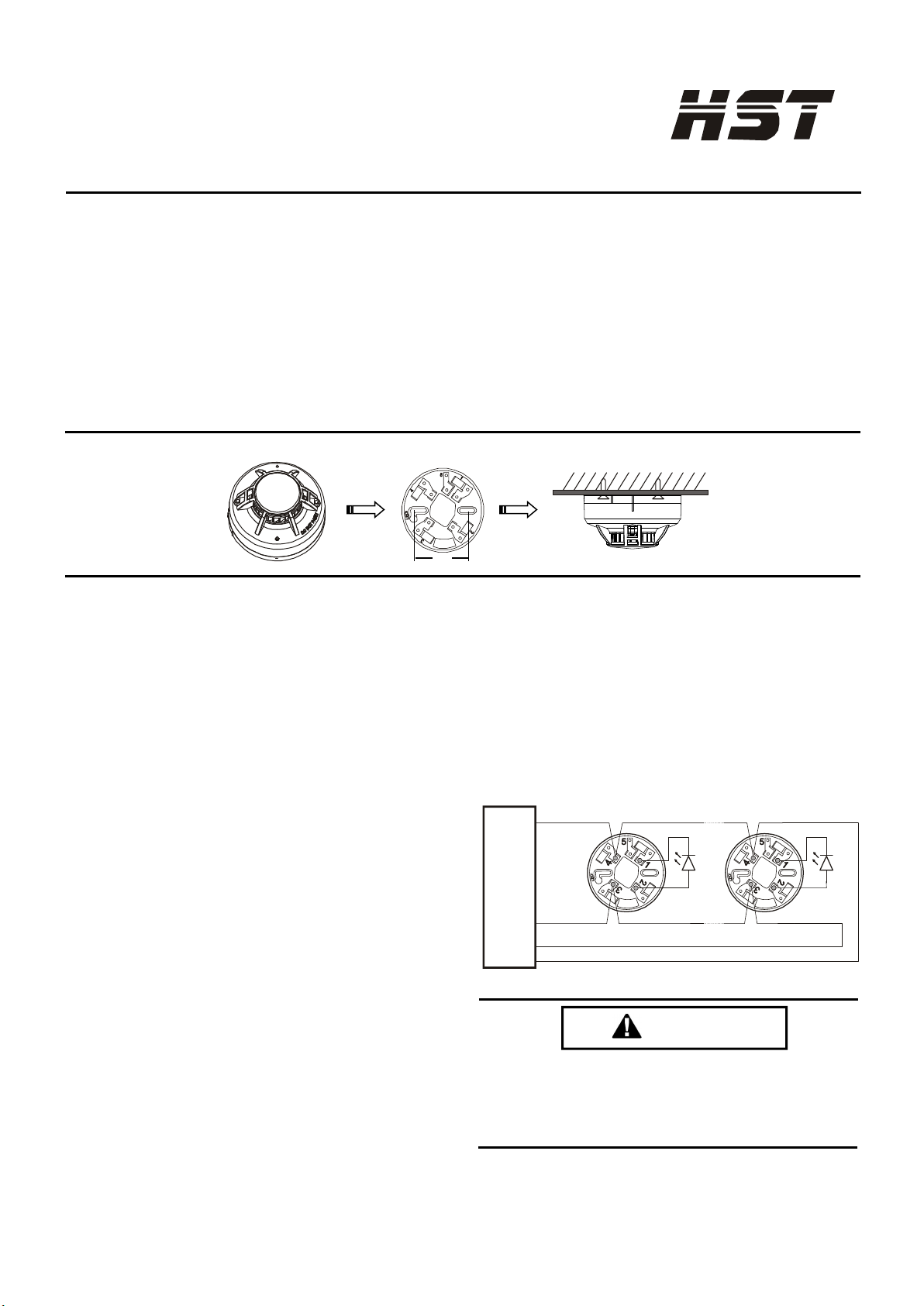

2. Remove the sensor cover by pressing firmly on each

of the four removal tabs that hold the cover in place.

3. Vacuum the screen carefully without removing it. If

further cleaning is required continue with Step 4,

otherwise skip to Step 7.

4. Remove the chamber cover/screen assembly by

5. Use a vacuum cleaner or compressed air to remove

dust and debris from the sensing chamber.

6. Reinstall the chamber cover/screen assembly by

sliding the edge over the sensing chamber. Turn until

7. Replace the cover using the LEDs to align the cover

and then gently pushing it until it locks into place.

8. Reinstall the detector.

9. Test the detector as described in TESTING.

10. Reconnect disabled circuits.

11. Notify the proper authorities that the system is back

THREE-YEAR LIMITED WARRANTY

We warrants its enclosed smoke detector to be free from defects in materials and workmanship under normal use and service for a period of three years from date of

manufacture. We makes no other express warranty for this smoke detector. No agent, representative, dealer, or employee of the Company has the authority to increase or

alter the obligations or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the repair or replacement of any part of the smoke

detector which is found to be defective in materials or workmanship under normal use and service during the three year period commencing with the date of manufacture.

After phoning Convoy Security’s technical support number for a Return Authorization number, send defective units postage prepaid to Convoy Security local

representative office. Please include a note describing the malfunction and suspected cause of failure. The Company shall not be obligated to repair or replace units which

are found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no case shall the Company be

liable for any consequential or incidental damages for breach of this or any other Warranty, expressed or implied whatsoever, even if the loss or damage is caused by the

Company’s negligence or fault. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not

apply to you. This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

FCC STATEMENT

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause Harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

–Reorient or relocate the receiving antenna.

–Increase the separation between the equipment and receiver.

–Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Please refer to insert for the Limitations of Fire Alarm Systems