CG1-2A H Beam cutter

- 5 -

1.2.6 Safety precautions for skin burns

Observe the safety precautions to prevent skin burns. Ignoring heat, spatter, and sparks

during operation could cause a fire or burned skin.

1. Do not perform cutting near flammables. (Move flammables well away from the sparks.)

2. Do not cut containers filled with flammables.

3. Do not keep lighters, matches, and other flammables nearby.

4. Flames from the torch will burn the skin. Keep your body away from the torch and tip, and

check the safety before operating the switches and valves.

5. Wear the correct protectors to protect your eyes and body.

6. Correctly tighten the tip to prevent backfire.

● When fixing a tip to the torch, tighten the nut with the two wrenches attached.

● If the tip is tighten excessively, it will be heated during cutting and tightened still more,

making it difficult to remove the tip.

● Avoid damaging the taper of the tip since this may cause backfire.

7. Check with soapsuds for any leakage of gas from the connection part of the distributor,

hoses and torch. Never use oil or grease on the connection of the oxygen pipe to avoid

backfire which may lead to explosion.

8. Be sure to check the following when igniting:

●Place the torch on the torch holder before igniting.

●Wear the required protectors (gauntlets, helmet, goggles, etc.)

● Check for any obstacles, dangerous materials and flammables near or in the direction of

cutting.

● The surface temperature is very high, so do not touch it even you wear gauntlets.

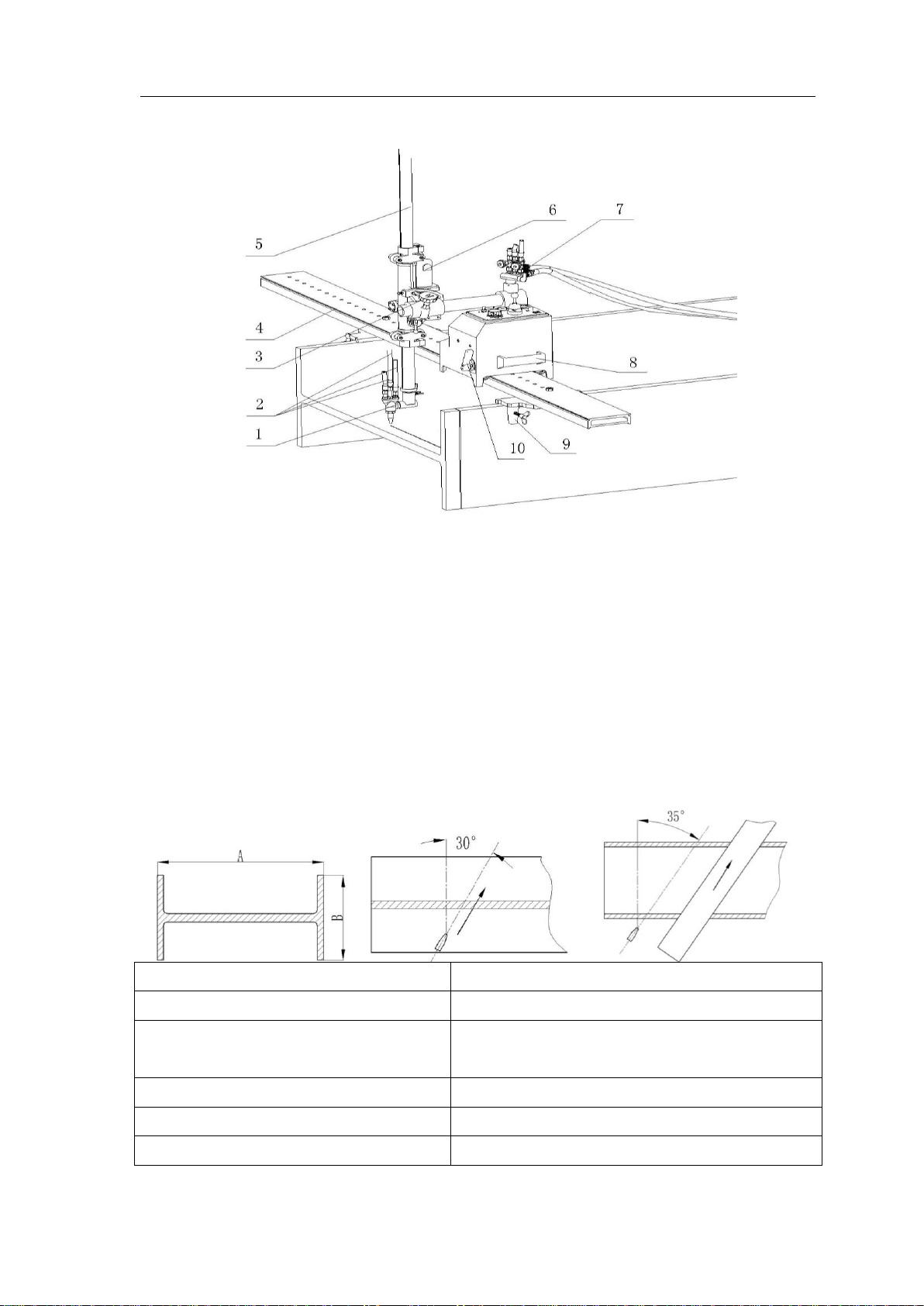

Outline of machine

2.1 Features of machine

“CG1-2A” portable H Structural section gas cutter is designed for cutting large-sized

structural section. The cutter is constituted of web plate cutting mechanism, wing plate

cutting mechanism, control box, gas distributor and torch. The shell of cutter is made of

aluminum. Every section is connected with web plate cutting mechanism. The web plate

mechanism is composed of box of reducing speed, motor and clutch. The web plate cutting

mechanism walks on the track with four rollers. The wing plate cutting mechanism is installed

on one side of the web plate and four pulley sustaining bars move vertically in the way that

gear moves with gear rack. Design of the cutter is reasonable and the cutter is easy to check

and repair. All operations are completed on the control panel such as quadruple switches,

quick return push-button, speed modulation, power source switch. It is easy to master the

operations even if freshman.