1

Precautions

Following All Safety Precautions

Before any operations, read the instructions and precautions in this document carefully to minimize the possibility

of accidents.

The Danger, Caution, and Note items in this document do not cover all the safety precautions that must be

observed. They provide only the generic safety precautions for operations.

When operating Huawei products and equipment, you must comply with safety precautions and special safety

instructions relevant to the corresponding equipment provided by Huawei. The safety precautions in this

document are relevant only to Huawei products. Huawei is not liable for any consequence that results from

violation of universal regulations for safety operations and safety codes on design, production, and equipment use.

Complying with Local Safety Regulations

When operating the product or equipment, comply with local safety regulations.

Qualified Personnel Only

Installation and maintenance personnel must be trained to perform operations correctly and safely.

Personnel Safety

The high-voltage power supply provides power for running the system. Avoid direct contact with the high-voltage

power supply or contact through damp objects. Failure to do so causes serious injury or death.

Non-standard and incorrect operations on the high-voltage power supply may result in fire and electric shock.

Do not perform operations on high-voltage and AC power supply facilities or on a tower or mast in the case of

thunderstorm. Failure to do so causes serious injury or death.

Ground the device before powering it on. Failure to do so causes damage to the device or personal injury.

Power off the device before performing operations on the power supply facilities.

High power radio-frequency signals are harmful to the human body. Ensure that the transmitter antennas are

muted before installing or maintaining an antenna on a tower or mast that holds a large number of transmitter

antennas.

Do not stand close to, or look into the optical fiber outlet without eye protection when handling optical fibers.

Take preventive measures when drilling holes. Otherwise, dust may hurt your eyes or you may inhale the dust.

Power off the batteries before connecting the cables to the batteries. Failure to do so causes personal injury.

When working at heights, be cautious about falling objects.

Device Safety

Check the electrical connection of the device before operation and ensure that the device is securely grounded.

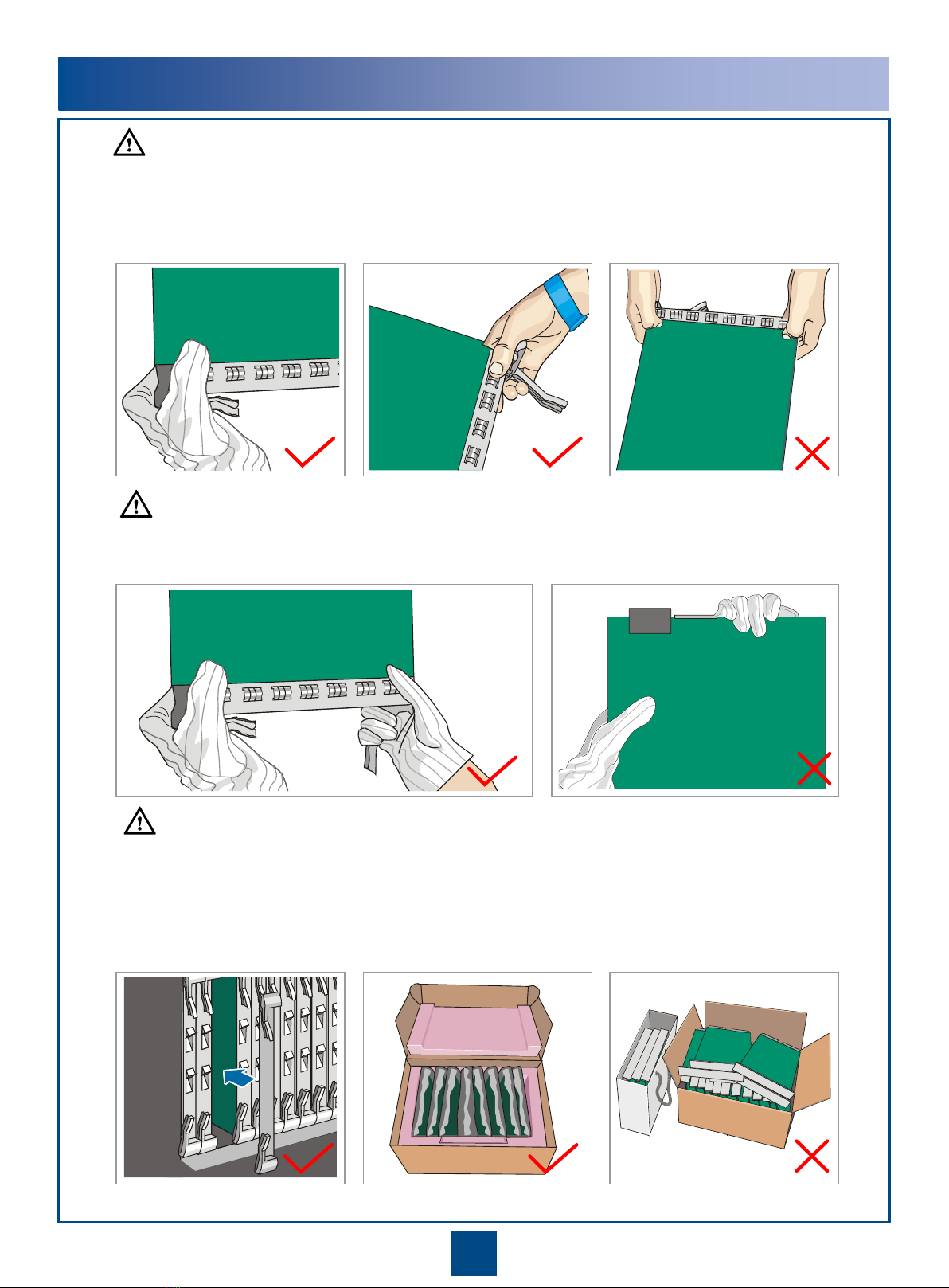

The static electricity discharged from the human body may damage the electrostatic sensitive components, such

as large-scale integrated circuits (LSIs), on the circuit board. Wear an ESD wrist strap or ESD gloves when

handling a circuit board.

When operating batteries, take proper measures to prevent short circuits in the batteries and electrolyte spill or

loss. The electrolyte may erode metal and boards, or even cause rust of the equipment or short circuits in the

boards.