1.Safety information

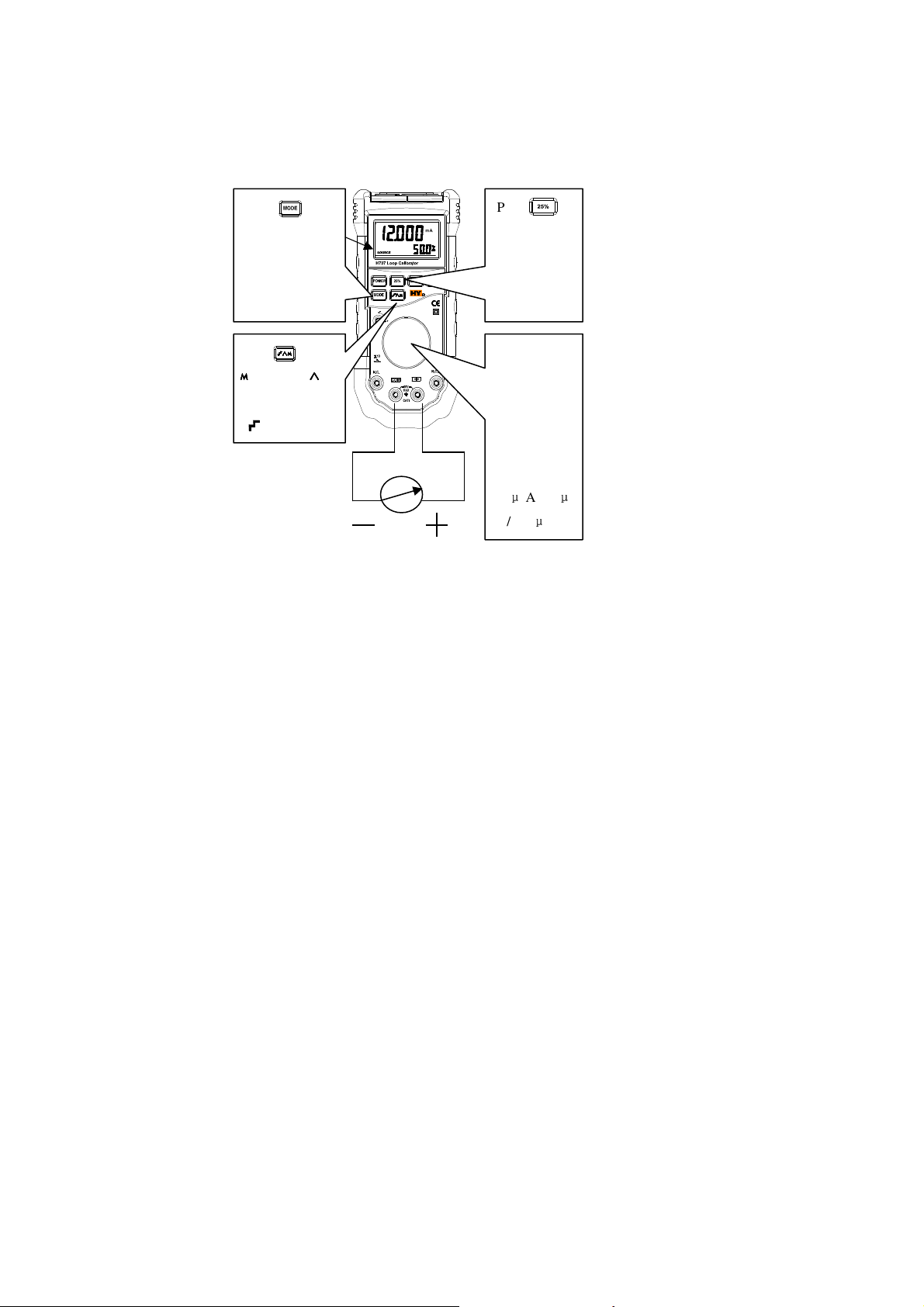

H707 Loop Calibrator (

hereafter to be referred as “Calibrator”

) is an

accurate tool for current supplying and measuring. The calibrator can deliver

source output 0-24mA and simulate two-wire transducer output 0-24mA, and can

measure 0-20mA or 4-20mA current loop, as well as measure DC voltage up to

28V.

This calibrator is an instrument subjects to IEC61010, CAT I 30V and

Pollution grade

Ⅱ

.

1.1 Warnings and notes

To avoid electric shock, personal injury or damage to the calibrator:

• Please use this calibrator following the guidance of this instruction, or the

protection provided by this instrument may be failed.

• Never use this calibrator near explosive gas, vapor or dust.

• Check the calibrator before using, if any damage found, please be sure not to

use.

• Check and test if the insulativity of lead wire is in good condition, and if there

is any damaged or exposed metal. Replace the damaged test wire.

• Never apply voltage above 30 V to between any two terminals or between any

terminal and the earth.

• Be sure to use proper terminal and model when measuring or supplying current.

• To avoid damage to this instrument when testing, it shall set the calibrator to

proper model before connecting the test wire.

• When connecting, it shall connect the COM test wire first, and then connect the

wire to be used; when disconnecting, it shall disconnect the wire to be used

first, and then disconnect the COM test wire.

• Never use this calibrator when the housing cover is open.