P/N KIL00912478 FORM NO. K1287 1007 ERO-7-005-06 Side 1 of 2

HUBBELL ELECTRICAL PRODUCTS

A Division of HUBBELL INCORPORATED (Delaware)

3940 Martin Luther King Drive

St. Louis, Missouri 63113 USA

www.Hubbell-Killark.com

INSTALLATION, OPERATION & MAINTENANCE DATA SHEET

FOR

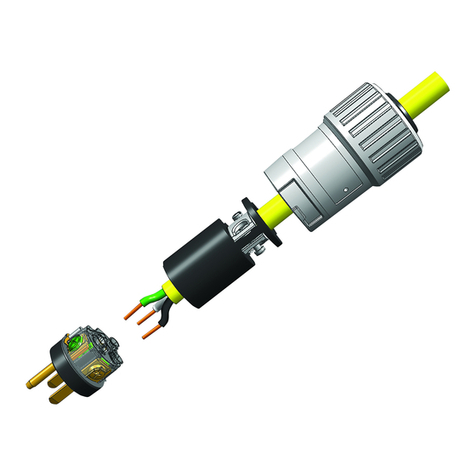

VSI30 Series Receptacles and Plugs

30 Amp Receptacle VSI30R and Plug VSI30P

For Hazardous and Corrosive Applications

Please read this entire document

before beginning any work.

1. Safety Instructions 3.2 Conduit/Cable Installation

Installation and maintenance of these plugs and receptacles

should only be performed by skilled and experienced

personnel in accordance with the National Electrical Code

(NEC) (NFPA 70) and any local regulations which relate to

hazardous (classified) locations.

For conduit installation, connect rigid conduit to the hub and

avoid misalignment.

For cable installation, connect a listed cable fitting.

Conduit or cable fittings should not be tightened more than 50

ft-lbs (68 N-m) of torque.

CAUTION:

∗Disconnect power supply before installing or servicing

these plugs and/or receptacles.

∗A modification to this product, other than noted on this form,

is not permitted.

∗Operate only undamaged and clean plugs & receptacles with

observations of the operating parameters in section 2.

∗For a Class I Zone 1 conduit installation, conduit seals are

required; refer to NEC 505.16 (B) (1). For any other cable or

conduit installation NO seals are required.

∗Use only approved wiring methods for the location, with the

associated conduit/cable fittings.

∗The receptacle is suitable for use on a circuit capable of

delivering not more than 10,000 rms symmetrical amperes,

600V maximum, when protected by properly sized Class J

fuses.

2. Technical Data

Please refer to the technical data on the nameplates.

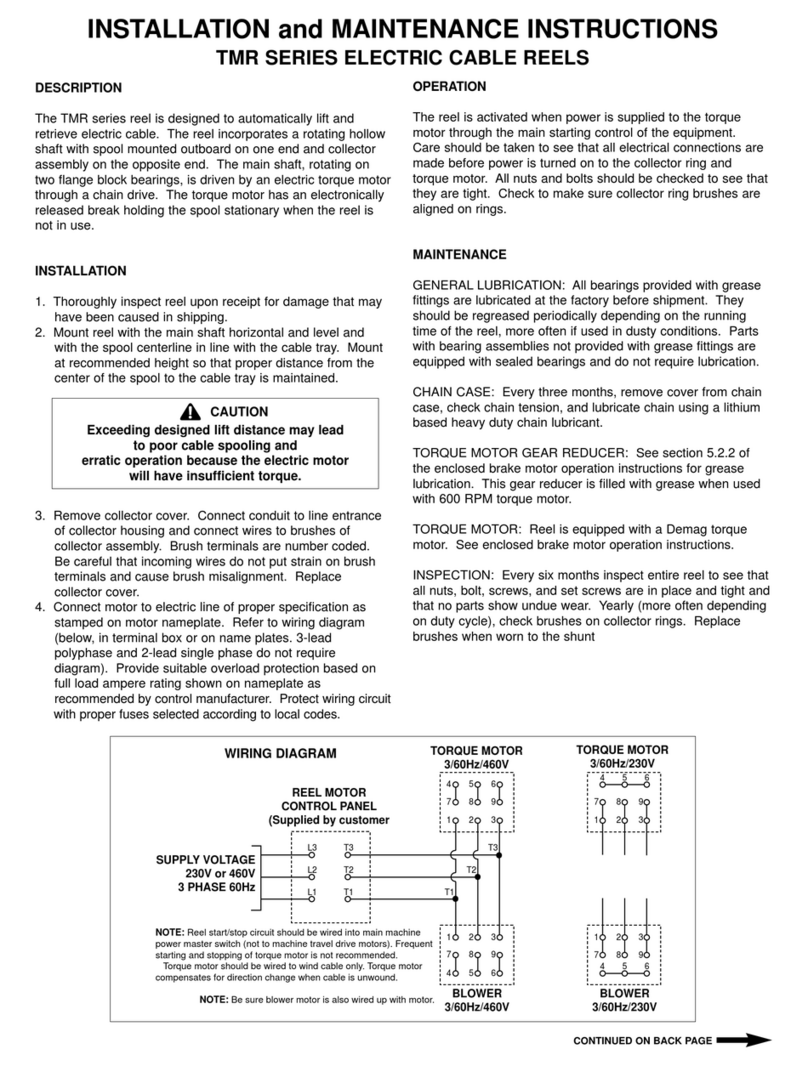

3.3 Wiring

Open the terminal cover and connect the supply conductors. If

Tais < 45°C, use 75°C rated wire; if Tais > 45°C use

90°C wire. The terminals accept up to two wires which are 14

AWG through 8 AWG per terminal. Allow proper length for

bending and cut the conductors to length. Strip the conductor

insulation 13/32" (10 mm) from the end. Insert the conductors

into the appropriate terminals which are marked to correspond

with the markings inside the plug. Torque all terminal screws to

16 in-lbs (1.8 N-m); including all unused terminals.

3.4 Installation of Auxiliary Contact Block (optional)

One or two blocks, either for I.S. or

non-I.S. circuits can be installed by

snapping them into either side of the

main terminal block. These contact

blocks also can be retrofitted and

must be installed according to IOM

Form No. K1289. See Parts and Accessories for block types.

2.1 Certification:

FM Project: 3024590 & CSA File 240743

Class I, Zone 1 & 2, AEx de IIC T*

Ex de IIC T*

Class I, Division 2, Groups ABCD;

Class II, Division 1&2, Groups EFG; Class III

*Temp. Class T6 at Ta<40°C, T5 at Ta<55°C.

3.5 Installation of Additional Entries

Additional top and side wiring entries can be installed in the

receptacle by punching through hole(s) 1-3/8" nominal dia. for

1" NPT. Use the mounting kit P/N YOST8571801290. The kit

contains one brass bonding plate, two locknuts with two 1"

NPT threaded holes and one bonding jumper with connection

2.2 Ambient temperature range:

-22°F to +131°F (-30°C to +55°C). screw. Insert entry fitting through the enclosure hole, tighten

into the bonding plate and secure with locknut. Connect the

2.3 Storage temperature range:

-67°F to +212°F (-55°C to +100°C). bonding jumper to the terminal marked . A second 1" NPT

bottom fitting can be installed by removing the close-up plug

2.4 Environmental protection: IP 66 / Type 3, 4, 4X.

Covers must be tight when plug is not inserted to maintain

environmental protection. Observe the labels on the plug and

and installing a 1" NPT fitting with locknut in it’s’ place. See

Parts and Accessories.

4. Horsepower Rating

receptacle.

3. Receptacle Installation

3.1 Enclosure mounting

Securely mount the receptacle in a vertical position using four

1/4" (6 mm) screws and suitable washers. Dimensions are

marked on the back of the receptacle housing.

Voltage AC 3-Phase

600V 25 HP SEE PLUG WIRING

480V 20 HP INSTRUCTIONS ON

240V 10 HP REVERSE SIDE

120V 5 HP